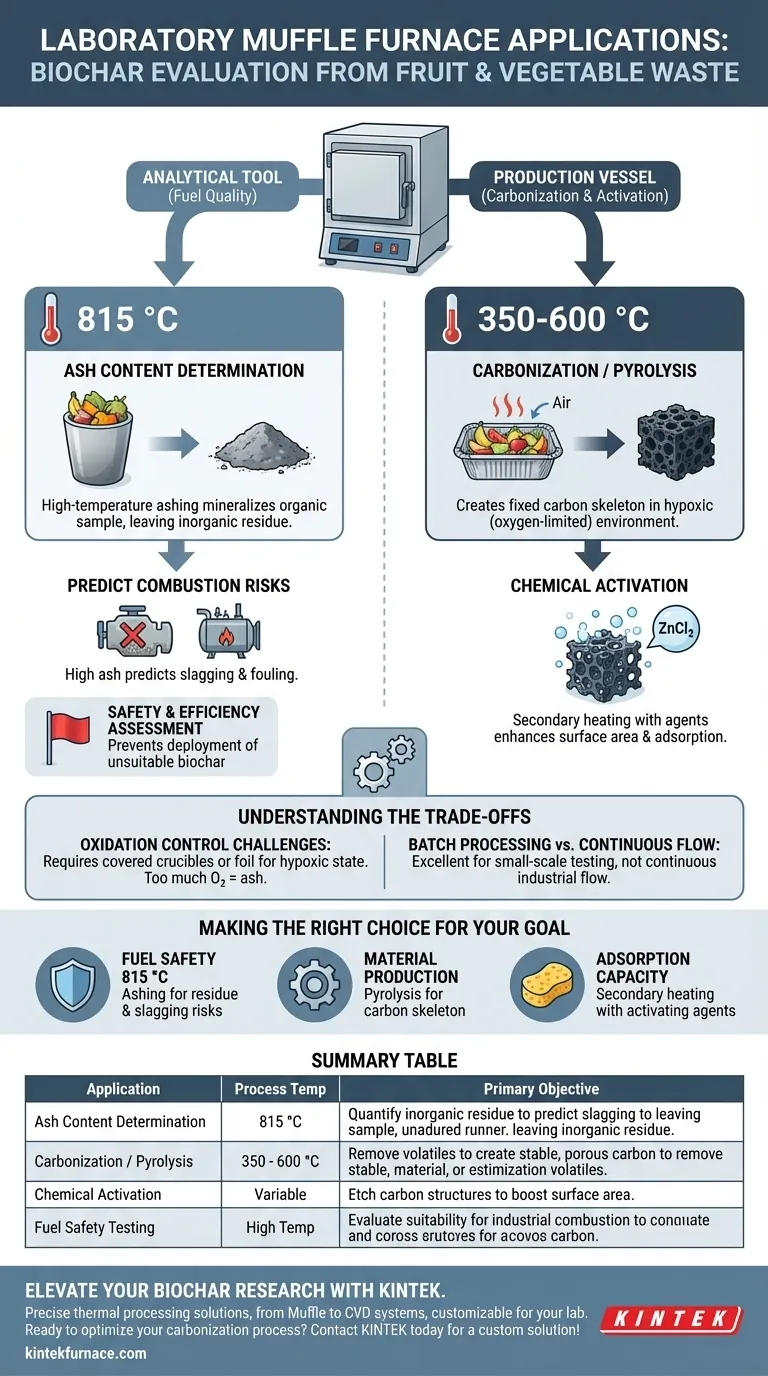

A laboratory muffle furnace serves two critical functions in biochar evaluation: it acts as an analytical tool for determining fuel quality through high-temperature ashing and as a production vessel for the carbonization and activation of raw biomass. Specifically, for fruit and vegetable waste, it provides the thermal stability required to measure inorganic residues or transform organic matter into a porous carbon framework.

Core Takeaway While often used solely for production, the muffle furnace is indispensable for predictive analysis of biochar fuel. It reveals the inorganic ash content that dictates whether a specific fruit or vegetable waste biochar will cause equipment failure (slagging and fouling) during combustion.

Analyzing Biochar Fuel Quality

The primary application of the muffle furnace in this context is quantitative analysis of the biochar's suitability as a fuel source.

Determination of Ash Content

To evaluate the purity of biochar, the furnace is used to perform high-temperature ashing, typically at 815 °C. This extreme heat completely mineralizes the organic sample, leaving behind only the inorganic residue.

Predicting Combustion Risks

High ash content in biomass—common in agricultural residues like pea shells—is a critical red flag. By isolating this residue, you can predict the likelihood of slagging and fouling in combustion engines or boilers.

Safety and Efficiency Assessment

If the muffle furnace reveals a high percentage of inorganic residue, the biochar may be unsuitable for certain high-efficiency energy applications. This step prevents the deployment of biochar that could damage industrial equipment.

Facilitating Carbonization and Pyrolysis

Beyond analysis, the muffle furnace is used to physically create the biochar through controlled thermal decomposition.

Establishing the Carbon Skeleton

For vegetable waste (such as pulse-based biomass), the furnace provides a constant high-temperature environment (e.g., 600 °C) to remove volatile components. This process, known as pyrolysis, transforms the raw plant residue into a fixed carbon skeleton.

Creating a Hypoxic Environment

Unlike open combustion, this process requires oxygen-limited conditions to prevent the sample from burning away. Techniques such as compressing waste into aluminum foil boxes allow the muffle furnace to maintain the necessary hypoxic state for thermochemical conversion.

Chemical Activation and Modification

The furnace is also used for secondary thermal decomposition to enhance the biochar's properties. By heating the char with agents like zinc chloride, the furnace facilitates the etching of the carbon structure to significantly increase its specific surface area and adsorption capabilities.

Understanding the Trade-offs

While versatile, the muffle furnace has specific limitations compared to other laboratory equipment like tube furnaces.

Oxidation Control Challenges

Muffle furnaces generally contain ambient air, making it difficult to achieve a strictly anaerobic environment without using covered crucibles or foil packets. If the sample is exposed to too much oxygen during pyrolysis, it will turn to ash rather than biochar.

Batch Processing vs. Continuous Flow

These furnaces are typically designed for batch processing. This makes them excellent for small-scale evaluating and testing, but less suitable for simulating continuous industrial production flows.

Making the Right Choice for Your Goal

- If your primary focus is Fuel Safety: Prioritize high-temperature ashing at 815 °C to determine the inorganic residue and assess slagging risks.

- If your primary focus is Material Production: Use the furnace at 350–600 °C with oxygen-limiting containers to fix the carbon skeleton and remove volatiles.

- If your primary focus is Adsorption Capacity: Utilize a secondary heating stage with chemical activating agents to etch the pore structure and increase surface area.

The muffle furnace is not just a heater; it is a dual-purpose instrument that allows you to both manufacture the carbon framework and rigorously stress-test its chemical viability.

Summary Table:

| Application | Process Temperature | Primary Objective |

|---|---|---|

| Ash Content Determination | 815 °C | Quantify inorganic residue to predict slagging and fouling risks. |

| Carbonization / Pyrolysis | 350 - 600 °C | Remove volatiles to create a stable, porous carbon skeleton. |

| Chemical Activation | Variable | Etch carbon structures with agents (e.g., ZnCl2) to boost surface area. |

| Fuel Safety Testing | High Temp | Evaluate suitability for industrial combustion engines and boilers. |

Elevate Your Biochar Research with KINTEK

Precise thermal processing is the key to transforming agricultural waste into high-value biochar. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific laboratory requirements.

Whether you are performing high-temperature ashing to prevent equipment slagging or developing advanced porous carbons through chemical activation, our high-temp furnaces provide the uniform heating and durability you need.

Ready to optimize your carbonization process? Contact KINTEK today for a custom solution!

Visual Guide

References

- Andreja Škorjanc, Danijela Urbancl. Advancing Energy Recovery: Evaluating Torrefaction Temperature Effects on Food Waste Properties from Fruit and Vegetable Processing. DOI: 10.3390/pr13010208

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are muffle furnaces used to determine moisture, ash, and volatile content in pharmaceutical materials? Essential for Precise Quality Control

- How does chamber size affect muffle furnace selection? Ensure Precision with the Right Fit

- What are the main benefits of using a muffle furnace? Achieve Precise, Contamination-Free Heating for Your Lab

- What role does a laboratory muffle furnace play in the ash analysis of plant samples? Achieve Clean Mineral Isolation

- How is a high-temperature box resistance furnace utilized in the self-ignition process? Enhance Catalyst Performance

- What emergency preparedness measures should be taken when using a muffle furnace? Ensure Safety and Prevent Hazards

- How is an industrial muffle furnace used to assess the ash content of biomass fibers? Master High-Temp Calcination

- How is the furnace door of a box type resistance furnace secured and operated? Ensure Safety and Efficiency in Your Lab