In short, muffle furnaces are used for these analyses because they provide an extremely precise, high-temperature, and controlled environment. This allows analysts to systematically break down a pharmaceutical sample by heat—first driving off water, then burning off organic volatile matter, and finally leaving only the inorganic ash. This step-by-step decomposition is essential for quantifying the exact composition of a drug or raw material.

The use of a muffle furnace is not just about measuring components; it is about fundamentally verifying the purity, stability, and safety of a pharmaceutical product. It provides the controlled conditions necessary to isolate and quantify contaminants or verify the correct material composition, which are non-negotiable requirements in the industry.

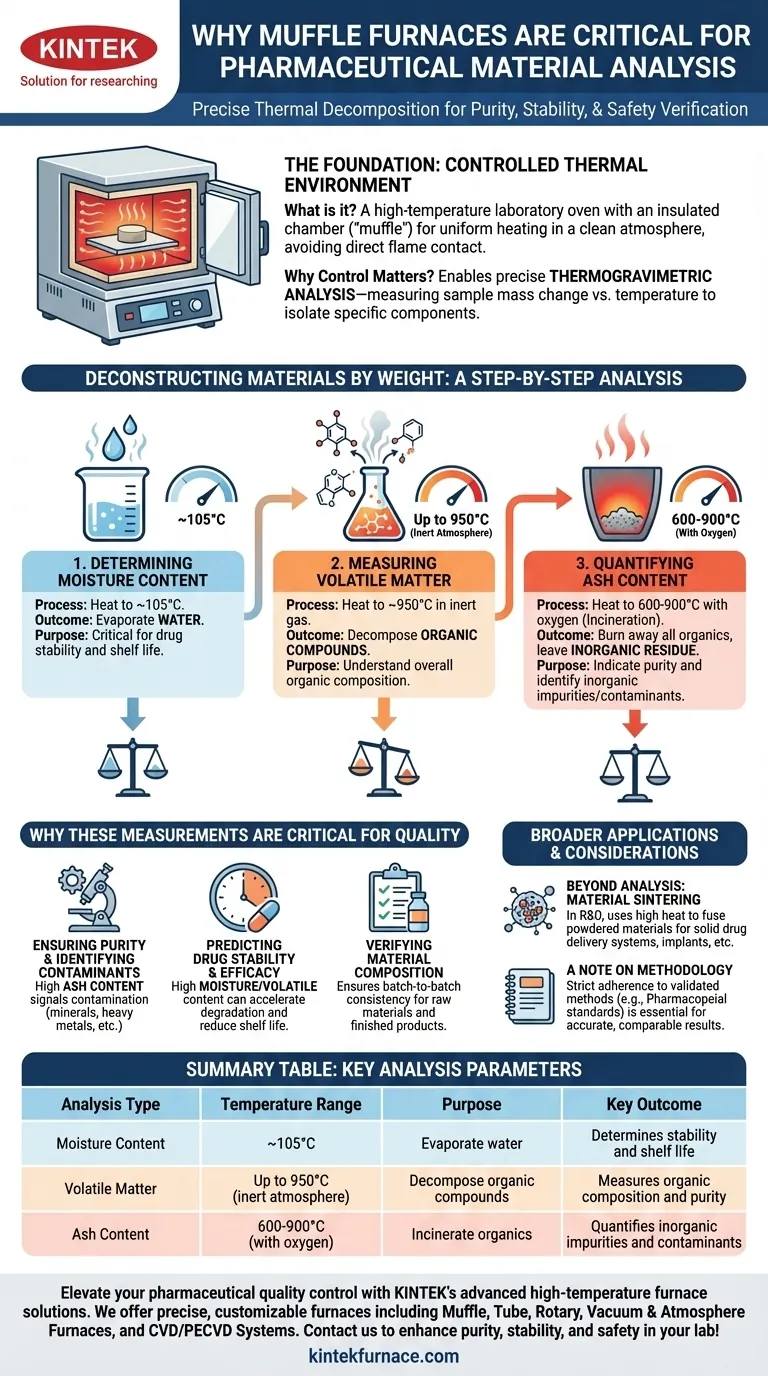

The Foundation: Controlled Thermal Environment

What is a Muffle Furnace?

A muffle furnace is essentially a high-temperature laboratory oven. Its defining feature is an insulated inner chamber (the "muffle") that heats the sample without exposing it to direct flames or combustion contaminants.

This design ensures that the sample is heated uniformly and in a clean atmosphere, which is critical for achieving accurate and repeatable analytical results.

Why Control is Everything in Analysis

In pharmaceutical analysis, results must be precise and reproducible. The muffle furnace’s ability to maintain a specific temperature for a set duration is its primary advantage.

This level of control allows for thermogravimetric analysis, where changes in a sample's mass are measured as the temperature changes. By controlling the temperature precisely, we can isolate and measure specific components.

Deconstructing Materials by Weight

The core analytical process involves heating a sample to progressively higher temperatures and weighing it at each stage. The weight loss at each step corresponds to a specific component.

Determining Moisture Content

First, a sample is heated to a relatively low temperature, typically just above the boiling point of water (~105°C).

The resulting weight loss is attributed purely to the evaporation of moisture. This is a critical first step, as excess moisture can significantly impact a drug's stability and shelf life.

Measuring Volatile Matter

Next, the temperature is increased significantly (e.g., to 950°C in an inert atmosphere) to force the decomposition and release of volatile matter.

This includes a wide range of organic compounds within the material. The weight lost during this stage represents the volatile content, which is crucial for understanding the product's overall organic composition.

Quantifying Ash Content

Finally, the sample is heated to a very high temperature (e.g., 600-900°C) in the presence of oxygen. This process, known as ashing or incineration, completely burns away all organic and volatile substances.

The residue left behind is the ash content, which consists of non-combustible inorganic materials like salts, minerals, or metallic impurities.

Why These Measurements Are Critical for Quality

These analyses are not academic exercises; they are pillars of pharmaceutical quality control (QC) and research.

Ensuring Purity and Identifying Contaminants

The ash content is a direct indicator of inorganic purity. An unexpectedly high ash value can signal contamination with minerals, heavy metals, or residual catalysts from the manufacturing process.

Predicting Drug Stability and Efficacy

High moisture or volatile content can indicate that a drug substance or excipient is unstable. These components can accelerate chemical degradation, potentially reducing the drug's efficacy and shelf life.

Verifying Material Composition

For raw materials and finished products, these tests verify that the composition matches the specification. It is a fundamental method to ensure consistency from batch to batch.

Broader Applications and Considerations

While crucial for analysis, the capabilities of a muffle furnace extend into material manufacturing and require careful methodology.

Beyond Analysis: Material Sintering

In pharmaceutical R&D, muffle furnaces are used for sintering. This process uses high heat to fuse powdered materials together without melting them.

This technique is vital for creating certain solid drug delivery systems, ceramic-based implants, or biocompatible materials where precise density and porosity are required.

A Note on Methodology

The accuracy of these tests depends entirely on a validated method. The specific temperatures, heating times, and atmospheric conditions must be strictly followed according to official pharmacopeial standards to ensure the results are meaningful and comparable.

Making the Right Choice for Your Goal

The specific analysis you perform depends entirely on your objective.

- If your primary focus is quality control and purity: Ash content analysis is your most critical test to detect inorganic contaminants.

- If your primary focus is stability testing: Measuring moisture and volatile content is essential to predict how a material will behave over time.

- If your primary focus is materials research: The furnace's precise temperature control is key for developing new materials through processes like sintering and thermal degradation studies.

Ultimately, mastering the use of a muffle furnace provides a foundational tool for ensuring the quality and safety of pharmaceutical materials from raw ingredients to the final product.

Summary Table:

| Analysis Type | Temperature Range | Purpose | Key Outcome |

|---|---|---|---|

| Moisture Content | ~105°C | Evaporate water | Determines stability and shelf life |

| Volatile Matter | Up to 950°C (inert atmosphere) | Decompose organic compounds | Measures organic composition and purity |

| Ash Content | 600-900°C (with oxygen) | Incinerate organics | Quantifies inorganic impurities and contaminants |

Elevate your pharmaceutical quality control with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide precise, customizable furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure they meet your unique experimental needs for accurate moisture, ash, and volatile content analysis. Contact us today to discuss how our solutions can enhance purity, stability, and safety in your lab!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production