A laboratory muffle furnace functions as a high-precision oxidation chamber designed to isolate the mineral content of plant material. It generates a stable, high-temperature environment—typically up to 600°C—to facilitate the complete combustion of organic matter. By burning away carbon components through a process called "dry ashing," the furnace leaves behind only the inorganic residue necessary for subsequent chemical analysis.

Core Takeaway The muffle furnace is the primary tool for "dry ashing," a purification process that removes the organic "noise" from a sample. By thermally decomposing plant matter into clean ash, it creates the essential baseline required to accurately measure total mineral content and trace elements.

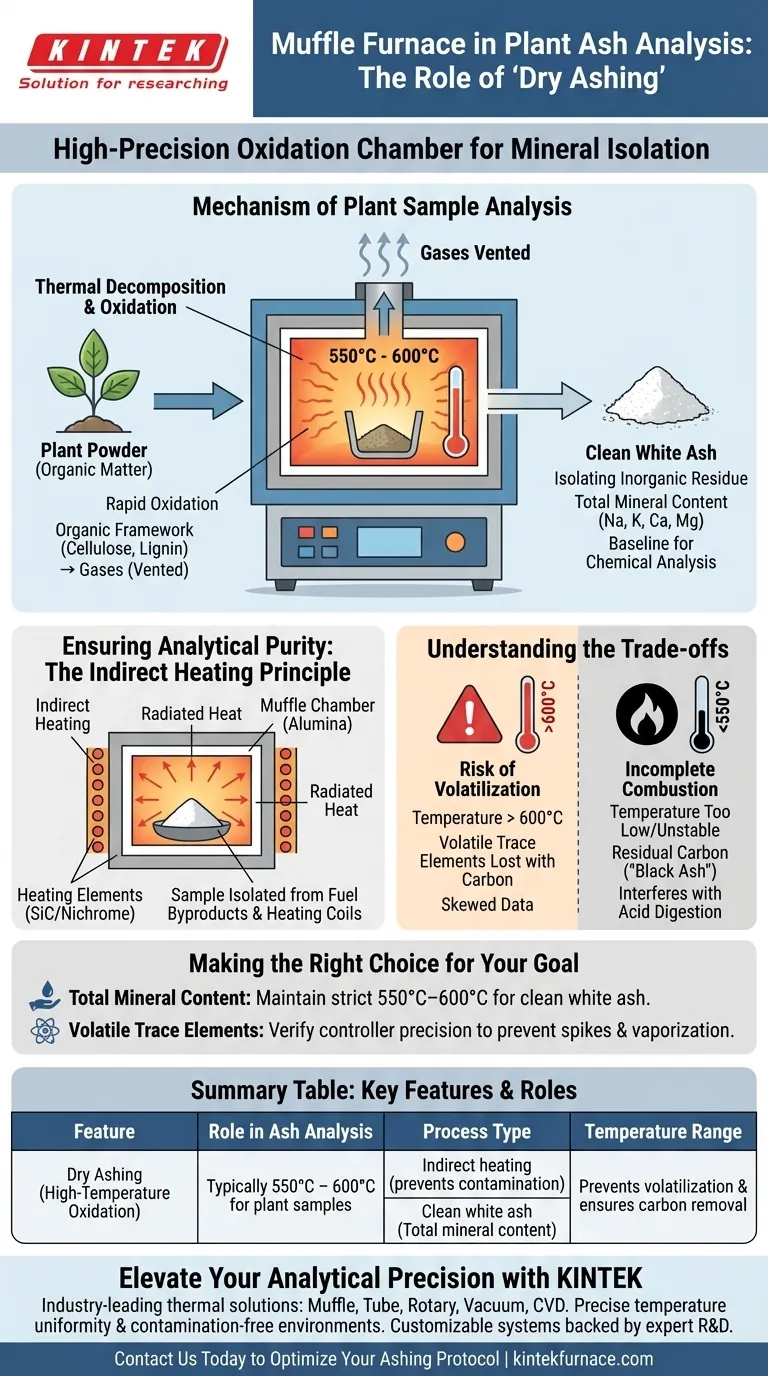

The Mechanism of Plant Sample Analysis

Thermal Decomposition and Oxidation

The primary role of the muffle furnace is to facilitate the complete thermal decomposition of plant powders.

When a sample is introduced to the furnace's environment (typically maintained between 550°C and 600°C), the intense heat triggers rapid oxidation.

This process converts the organic framework of the plant—cellulose, lignin, and proteins—into gases that are vented away, effectively removing the carbon matrix.

Isolating the Inorganic Residue

The ultimate output of this process is a substance known as clean white ash.

This ash represents the total inorganic mineral content of the plant sample.

Obtaining this residue is a non-negotiable prerequisite for further analytical steps, specifically the quantification of elements such as sodium, potassium, calcium, and magnesium.

Ensuring Analytical Purity

The Indirect Heating Principle

To ensure the ash analysis is accurate, the sample must never come into direct contact with the heating source.

Muffle furnaces utilize indirect heating, where electric heating elements (often silicon carbide or nichrome) are located outside the inner chamber (the muffle).

The muffle, typically made of high-temperature resistant alumina, absorbs this heat and radiates it evenly onto the sample.

Preventing Contamination

This isolation is the "muffle" in muffle furnace—it muffles or shields the sample from external impurities.

If a sample were exposed to fuel byproducts or direct contact with heating coils, the chemical composition of the ash could be altered.

By separating the combustion chamber from the heating source, the furnace guarantees that the resulting mineral data reflects only the plant sample, not the equipment.

Understanding the Trade-offs

The Risk of Volatilization

While high heat is necessary to remove organics, it presents a risk to certain volatile minerals.

If the furnace temperature exceeds the recommended 600°C threshold, specific trace elements may vaporize and be lost along with the carbon.

Strict adherence to temperature protocols is required to prevent data skewing.

Incomplete Combustion

Conversely, failing to maintain a sufficiently high or stable temperature results in "black ash."

This indicates the presence of residual carbon, which interferes with the subsequent acid digestion and chemical analysis.

The furnace's ability to maintain a constant temperature is just as critical as its maximum heat capability.

Making the Right Choice for Your Goal

To maximize the utility of a muffle furnace in your lab, align your parameters with your specific analytical targets:

- If your primary focus is Total Mineral Content: Ensure the furnace is capable of maintaining a strict 550°C–600°C range to yield clean white ash without black carbon residue.

- If your primary focus is Volatile Trace Elements: Verify the controller's precision to prevent temperature spikes that could cause element loss through vaporization.

The muffle furnace is not just a heater; it is the gatekeeper of purity that ensures your chemical quantification starts with a flawless, contaminant-free baseline.

Summary Table:

| Feature | Role in Ash Analysis |

|---|---|

| Process Type | Dry Ashing (High-Temperature Oxidation) |

| Temperature Range | Typically 550°C – 600°C for plant samples |

| Heating Method | Indirect heating to prevent sample contamination |

| Primary Output | Clean white ash (Total mineral content) |

| Critical Control | Prevents volatilization of trace elements & ensures complete carbon removal |

Elevate Your Analytical Precision with KINTEK

Don't let organic interference or temperature fluctuations compromise your research data. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered for the rigorous demands of laboratory analysis. Our high-temp furnaces offer the precise temperature uniformity and contamination-free environments essential for perfect dry ashing and mineral quantification.

Backed by expert R&D and manufacturing, we specialize in customizable systems tailored to your unique lab requirements.

Contact Us Today to Optimize Your Ashing Protocol

Visual Guide

References

- Janet Mbaluka Kivuva, Sebastian Chakeredza. Nutritional profiles and phytochemicals of sausage tree (Kigelia Africana) and moringa (Moringa oleifera) at Africa University, Zimbabwe. DOI: 10.22271/27893065.2025.v5.i2a.131

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of high-temperature calcination in a muffle furnace? Mastering Ce-TiO2 Catalyst Preparation

- What cooling strategy should be followed in a muffle furnace for BiFeO3 nanofibers? Ensure Structural Integrity

- What role does a muffle furnace play in the calcination modification of clinoptilolite? Optimize Zeolite Performance

- How does a programmable muffle furnace improve thin film crystal structure? Optimize Annealing for Precision Results

- What are the main functions of muffle furnaces in materials processing? Achieve Precise, Clean Thermal Control for Your Lab

- What function does a muffle furnace perform during the air calcination of ZnO-Co3O4? Optimize Your Nanocomposites

- Why is an industrial-grade burnout furnace required for enameled copper wire scrap? Ensure High Purity Copper Refining

- What is the function of Muffle Furnaces in raw material analysis? Optimize Energy Systems with Precise Qualification