At its core, a muffle furnace executes two critical functions: it provides exceptionally uniform high-temperature heating, and it isolates the material being processed from the heating elements and external contaminants. This combination allows for precise thermal processing in a tightly controlled environment, which is essential for developing and analyzing advanced materials.

While many instruments can generate heat, a muffle furnace is distinguished by its ability to deliver a clean, stable, and homogenous high-temperature environment. This makes it indispensable for any application where the material's final purity, structure, and properties are non-negotiable.

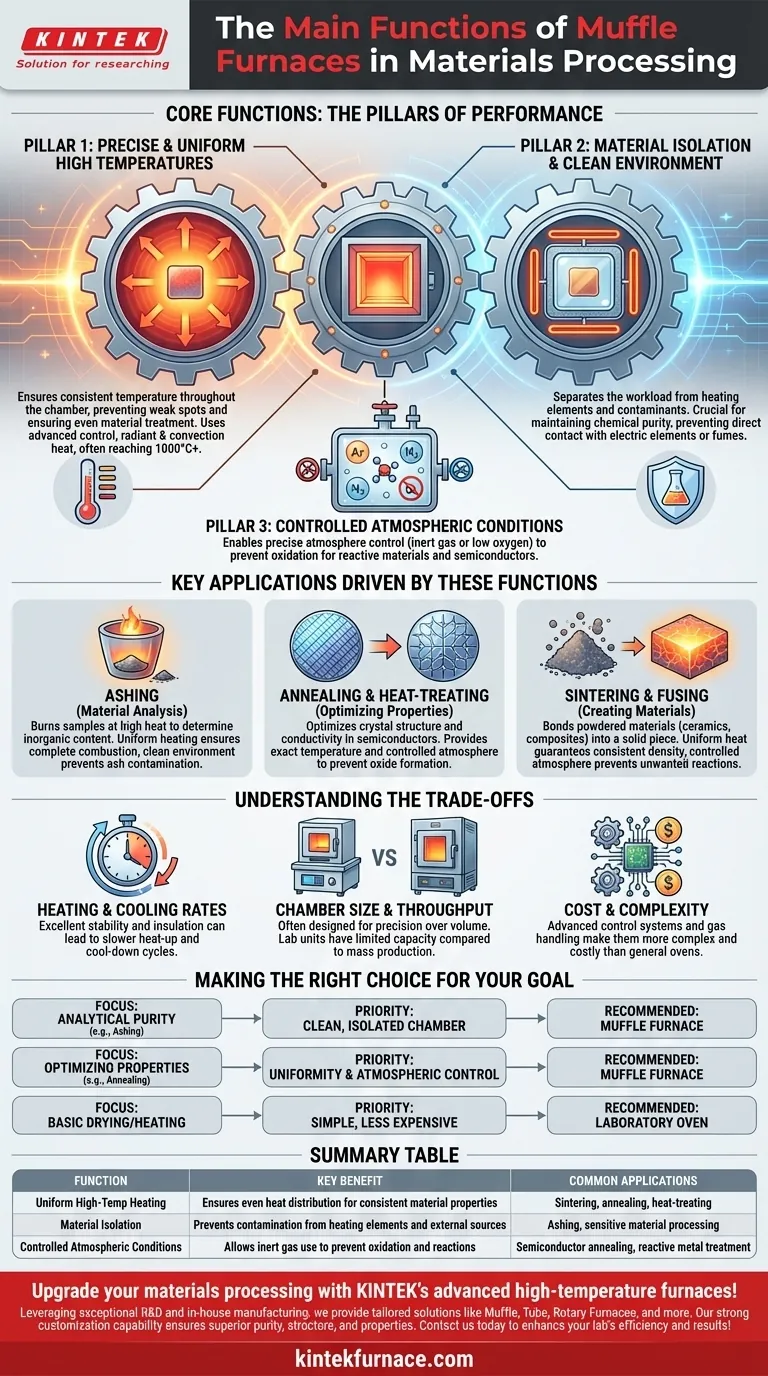

The Pillars of Muffle Furnace Function

A muffle furnace's value comes from its ability to perfectly manage the heating environment. This is built on two foundational principles: temperature control and material isolation.

Pillar 1: Achieving Precise and Uniform High Temperatures

A muffle furnace is engineered for thermal stability. Its design ensures that temperature is consistent throughout the entire processing chamber.

This uniformity is critical for guaranteeing that a workpiece or sample is treated evenly, preventing weak spots or inconsistent material properties. The furnace uses advanced control systems and a combination of radiant and convection heat to maintain a homogeneous temperature, often reaching 1000°C or higher.

Pillar 2: Isolating the Material in a Clean Environment

The term "muffle" refers to the inner chamber that encloses the material. This chamber separates the workload from the heating elements and any potential contaminants.

This separation is the furnace's defining feature. By preventing direct contact with electric elements or exposure to combustion fumes (in fuel-fired models), the muffle ensures the material's chemical purity is maintained. This clean operation is vital for sensitive processes.

Pillar 3: Enabling Controlled Atmospheric Conditions

Because the muffle creates a sealed chamber, it enables precise control over the atmosphere surrounding the material.

This function is crucial for materials that react with air at high temperatures. The chamber can be filled with an inert gas (like argon or nitrogen) to prevent oxidation, or operate in a low-oxygen environment. This capability is essential for heat-treating reactive metals or annealing semiconductors.

How These Functions Drive Key Applications

The unique capabilities of a muffle furnace make it the go-to instrument for a range of demanding thermal processes.

For Material Analysis: Ashing

In ashing, a sample is burned at a high temperature to determine its inorganic content. The furnace's uniform heating ensures complete combustion, while its clean environment prevents contamination of the residual ash, guaranteeing accurate analytical results.

For Optimizing Properties: Annealing and Heat-Treating

In semiconductor manufacturing, silicon wafers are annealed to optimize their crystal structure and conductivity. A muffle furnace provides the exact temperature required and a controlled atmosphere to prevent the formation of oxide layers that would ruin the electronic properties.

For Creating Materials: Sintering and Fusing

Sintering involves heating powdered materials until their particles bond together to form a solid piece. This is used to create advanced ceramics, composites, and alloys. The furnace's uniform heat ensures consistent density, and the controlled atmosphere prevents unwanted chemical reactions during formation.

Understanding the Trade-offs

While powerful, muffle furnaces are specialized tools with specific operational characteristics.

Heating and Cooling Rates

The heat-resistant refractory materials that provide excellent temperature stability and insulation also retain heat effectively. This can result in slower heat-up and cool-down cycles compared to less insulated ovens.

Chamber Size and Throughput

Many laboratory-scale muffle furnaces are designed for precision over volume. While large industrial models exist, the benchtop units common in research and development have limited capacity, making them better suited for sample processing than mass production.

Cost and Complexity

The features that enable precise temperature and atmospheric control—advanced sensors, controllers, and gas-handling systems—make muffle furnaces more complex and costly than general-purpose laboratory ovens.

Making the Right Choice for Your Goal

Selecting a heating method depends entirely on what you need to achieve with your material.

- If your primary focus is analytical purity (e.g., ashing): Your priority is the furnace's ability to provide a clean, isolated chamber that prevents any contamination of the sample.

- If your primary focus is optimizing material properties (e.g., annealing): You need a furnace with superior temperature uniformity and advanced atmospheric control to achieve specific structural changes without oxidation.

- If your primary focus is basic drying or heating non-reactive materials: A simpler, less expensive laboratory oven without a muffle may be sufficient for your needs.

Ultimately, a muffle furnace is the definitive tool when the integrity of your material cannot be compromised by the heating process itself.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Uniform High-Temperature Heating | Ensures even heat distribution for consistent material properties | Sintering, annealing, heat-treating |

| Material Isolation | Prevents contamination from heating elements and external sources | Ashing, sensitive material processing |

| Controlled Atmospheric Conditions | Allows inert gas use to prevent oxidation and reactions | Semiconductor annealing, reactive metal treatment |

Upgrade your materials processing with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior purity, structure, and properties. Contact us today to discuss how our furnaces can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation