At their core, muffle furnaces are popular because they provide a simple, cost-effective way to achieve precise, high-temperature heating in a clean and controlled environment. This unique combination makes them an indispensable workhorse for an incredibly wide range of industrial processes, from materials science research to routine quality control testing.

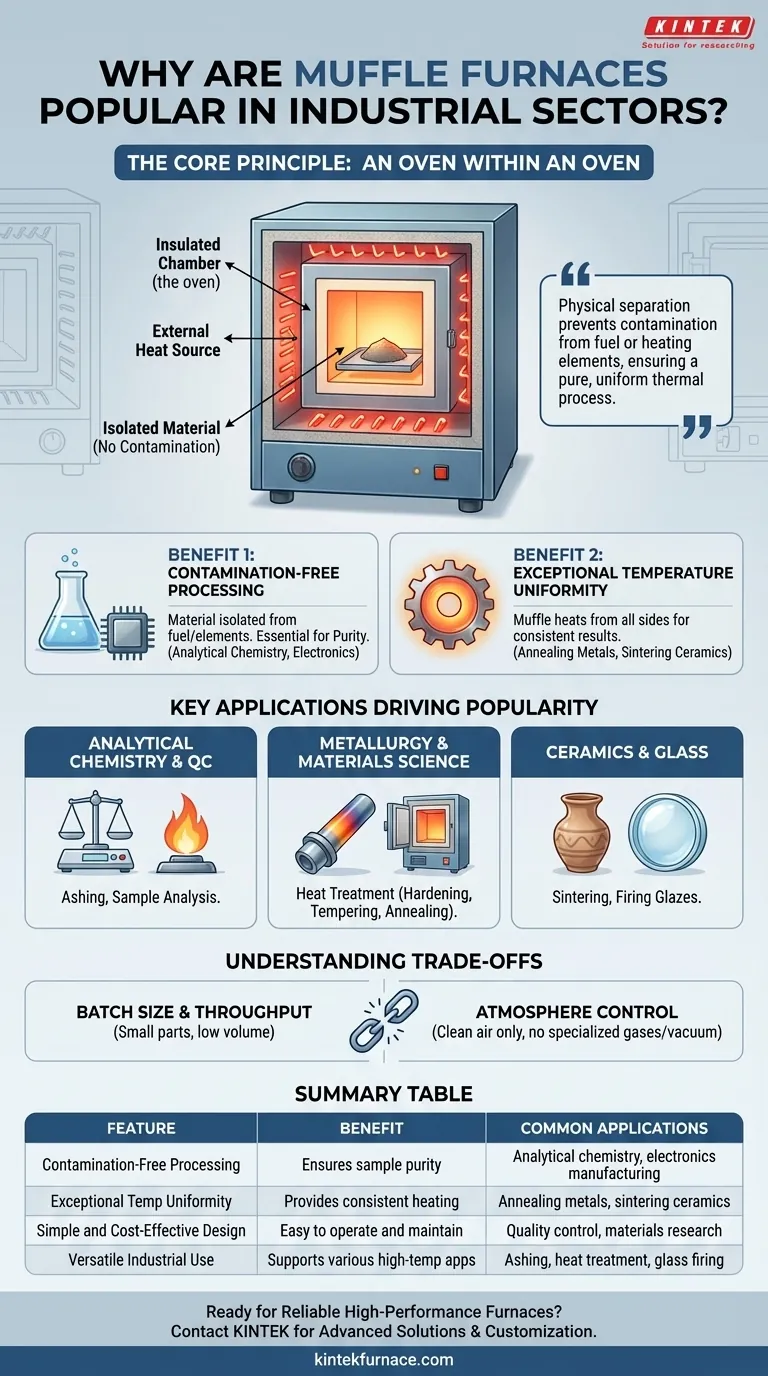

The defining feature of a muffle furnace is its design: the material being heated (the charge) is placed inside a sealed chamber, or "muffle," which is then heated externally. This physical separation prevents contamination from fuel or heating elements, ensuring a pure, uniform thermal process that is critical for countless applications.

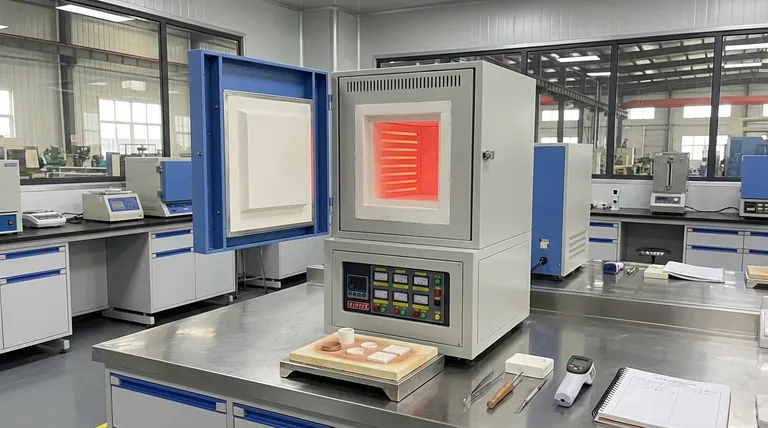

The Core Principle: An Oven Within an Oven

The term "muffle furnace" can be understood by thinking of it as an oven within an oven. This simple but powerful design principle is the source of its primary advantages.

The Power of Isolation

A muffle is a refractory box or chamber that isolates the workpiece from the direct heat source. In electric furnaces, it separates the material from the heating elements; in fuel-fired furnaces, it separates it from the flame and combustion gases.

This isolation is the furnace's key characteristic. Everything else about its performance stems from this fundamental design choice.

Benefit 1: Contamination-Free Processing

Because the material never comes into direct contact with the heating source, the risk of contamination is virtually eliminated.

This is non-negotiable in applications like analytical chemistry, where a sample's composition must remain unaltered, or in electronics, where impurities can ruin sensitive components.

Benefit 2: Exceptional Temperature Uniformity

Heating the muffle from all sides creates a highly uniform radiant heat environment inside the chamber. This ensures the entire workpiece receives the same temperature, preventing hot spots or inconsistencies.

This uniformity is critical for processes like annealing metals or sintering ceramics, where precise thermal profiles determine the final material properties.

Key Applications Driving Its Popularity

The muffle furnace's blend of purity and precision has made it a standard tool in nearly every industry that relies on thermal processing.

For Analytical Chemistry and Quality Control

Muffle furnaces are the industry standard for ashing, a process that burns off all organic matter to determine the non-combustible mineral content of a sample.

This is used everywhere from food science and environmental analysis to pharmaceutical drug testing and coal quality analysis.

For Metallurgy and Materials Science

Industries from aerospace to general manufacturing use muffle furnaces for heat treatment of small metal parts.

Processes like hardening, tempering, and annealing are used to alter the microstructure and mechanical properties of metals. The controlled, clean environment of a muffle furnace ensures these treatments are predictable and repeatable.

For Ceramics and Glass Manufacturing

The creation of advanced ceramics and specialized glass requires precise firing cycles. Muffle furnaces are used for sintering ceramic powders into solid components and for firing glazes.

The clean atmosphere prevents discoloration, and the uniform heat ensures the parts cure without stress or cracking.

Understanding the Trade-offs

While incredibly versatile, the muffle furnace is not the solution for every heating problem. Understanding its limitations is key to using it effectively.

Primary Limitation: Batch Size and Throughput

Traditional muffle furnaces are batch-style ovens, best suited for smaller parts or samples. They are not designed for continuous, high-volume production lines, where a tunnel or conveyor furnace would be more appropriate.

Secondary Limitation: Atmosphere Control

While a standard muffle furnace provides a clean air environment, it does not inherently control the atmosphere. For processes requiring specific inert gases (like argon or nitrogen) or a vacuum, a specialized atmosphere furnace or vacuum furnace is necessary.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the specific requirements of your process.

- If your primary focus is analytical purity and sample testing: The muffle furnace is the ideal tool for its contamination-free environment, making it essential for ashing and material analysis.

- If your primary focus is heat-treating small metal or ceramic parts: Its combination of temperature uniformity and operational simplicity provides a highly reliable and cost-effective solution.

- If your primary focus is high-volume production: A muffle furnace is likely too small and slow; investigate continuous or larger-scale batch furnaces designed for industrial throughput.

Ultimately, the muffle furnace's enduring popularity comes from mastering the fundamentals of clean, uniform, and accessible high-temperature processing.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Contamination-Free Processing | Ensures sample purity by isolating materials from heat sources | Analytical chemistry, electronics manufacturing |

| Exceptional Temperature Uniformity | Provides consistent heating for reliable results | Annealing metals, sintering ceramics |

| Simple and Cost-Effective Design | Easy to operate and maintain, ideal for labs and small-scale processes | Quality control, materials research |

| Versatile Industrial Use | Supports various high-temperature applications across sectors | Ashing, heat treatment, glass firing |

Ready to enhance your lab's thermal processing with reliable, high-performance furnaces? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today via our contact form to discuss how we can tailor a solution for your specific needs in metallurgy, ceramics, or analytical chemistry!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment