In short, vacuum muffle furnaces are essential in labs where high-temperature processes demand strict atmospheric control to prevent contamination or oxidation. They are most commonly found in facilities developing battery materials, conducting advanced materials science R&D, annealing medical-grade alloys, and heat-treating high-performance steel parts.

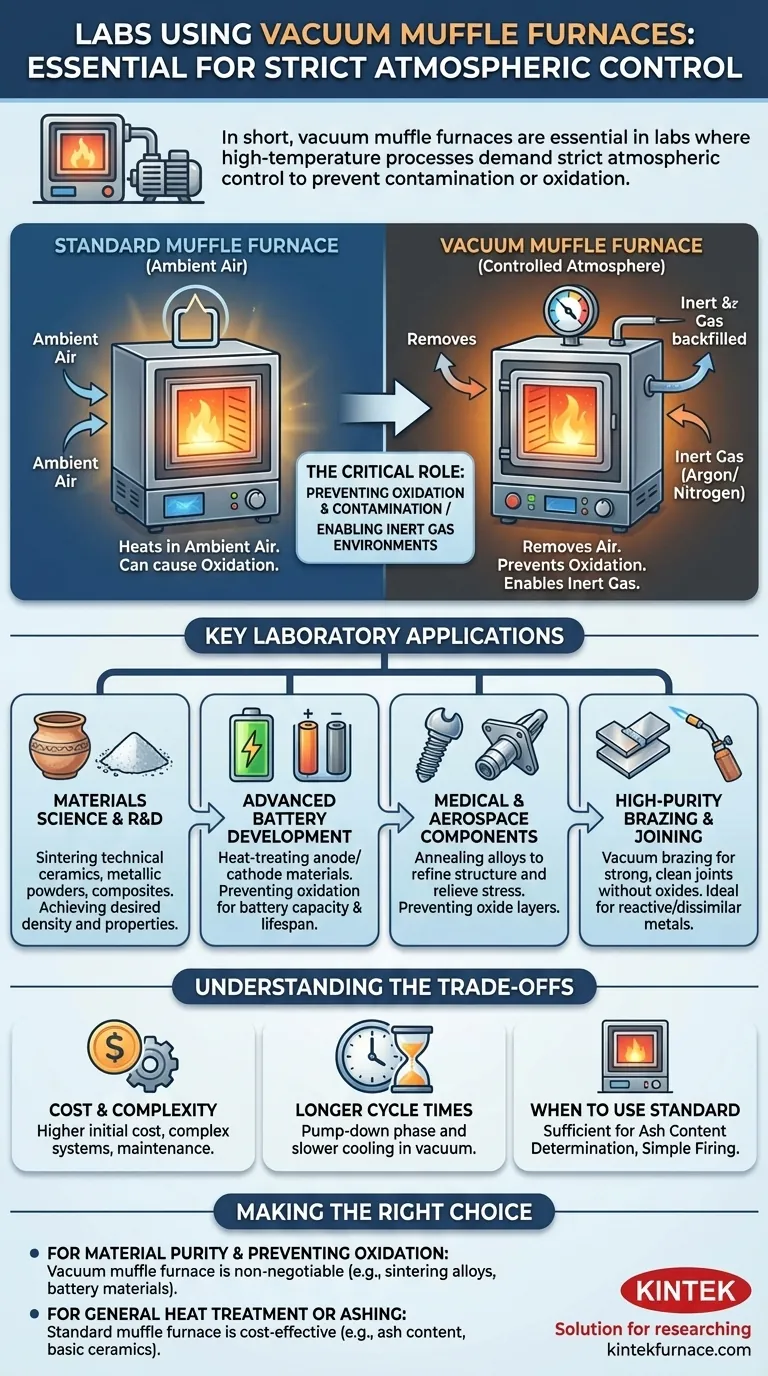

The core difference between a standard muffle furnace and a vacuum muffle furnace is atmospheric control. While a standard furnace heats materials in ambient air, a vacuum furnace first removes the air, creating a controlled environment essential for processing sensitive, reactive, or high-purity materials.

The Critical Role of Atmospheric Control

The decision to use a vacuum muffle furnace is almost always driven by the need to manage the environment surrounding the material being heated. At high temperatures, the oxygen and moisture in ambient air can fundamentally alter or ruin a workpiece.

Preventing Oxidation and Contamination

Many advanced materials, especially metals and alloys, will rapidly oxidize (rust or tarnish) when heated. This oxide layer can degrade the material's structural, electrical, or chemical properties.

A vacuum furnace removes the reactive gases, primarily oxygen, from the chamber. This allows materials to be heated to extreme temperatures without unwanted chemical reactions, ensuring their purity and performance.

Enabling Inert Gas Environments

Once a vacuum is achieved, the furnace chamber can be backfilled with a high-purity inert gas, such as argon or nitrogen.

This creates a stable, non-reactive atmosphere at a specific pressure. This technique is critical for processes like sintering, where powdered materials are fused together without melting, as it prevents oxidation while facilitating heat transfer.

Key Laboratory Applications

The need for a controlled atmosphere makes vacuum muffle furnaces indispensable in several high-tech fields. Each application leverages the furnace's ability to protect the material during thermal processing.

Materials Science and R&D

Laboratories researching new materials rely on vacuum furnaces for sintering technical ceramics, metallic powders, and composites. The oxygen-free environment is the only way to achieve the desired density and mechanical properties in many next-generation materials.

Advanced Battery Development

The creation of anode and cathode materials for lithium-ion batteries is an extremely sensitive process. Any oxidation or contamination introduced during heat treatment can severely degrade the battery's capacity, efficiency, and lifespan. Vacuum furnaces provide the necessary high-purity environment.

Medical and Aerospace Components

The manufacturing of medical devices, such as implants made from titanium alloys, requires annealing to refine the material's grain structure and relieve stress. A vacuum prevents the formation of an oxide layer that could compromise biocompatibility and strength. The same principle applies to heat-treating specialty steels for aerospace parts.

High-Purity Brazing and Joining

Brazing is a process used to join metals. Vacuum brazing is a superior technique for creating extremely strong, clean joints, especially with dissimilar or reactive metals. The vacuum ensures that no oxides form on the surfaces, allowing the brazing filler metal to flow cleanly and create a perfect bond.

Understanding the Trade-offs: Vacuum vs. Standard Furnace

While powerful, a vacuum muffle furnace is not always the right tool. Understanding its limitations is key to making a sound investment.

When a Standard Furnace Is Sufficient

For many common lab applications, atmospheric control is unnecessary or even counterproductive. Processes like ash content determination, simple ceramic firing, or analyzing non-combustible materials are designed to be performed in the presence of air. In these cases, a simpler, more-cost effective standard muffle furnace is the appropriate choice.

The Cost and Complexity Factor

Vacuum muffle furnaces are significantly more expensive than their standard counterparts. They require vacuum pumps, complex sealing systems, and more sophisticated controls, all of which add to the initial cost and long-term maintenance.

Longer Cycle Times

Achieving a deep vacuum takes time. The "pump-down" phase before heating and the often-slower cooling phase (as convection is reduced in a vacuum) mean that total cycle times are typically longer than in a standard furnace.

Making the Right Choice for Your Process

Your choice ultimately depends on the chemical and physical requirements of your material during heat treatment.

- If your primary focus is material purity and preventing oxidation: A vacuum muffle furnace is non-negotiable for processes like sintering advanced alloys, developing battery materials, or annealing reactive metals.

- If your primary focus is general heat treatment or ashing: A standard muffle furnace is the more cost-effective and straightforward choice for applications like determining ash content, firing basic ceramics, or heat-treating non-reactive metals.

- If you require a specific non-oxidizing atmosphere: A vacuum furnace is essential, as it provides the ability to first remove the air and then backfill the chamber with a precise inert gas like argon.

Understanding the role of the atmosphere is the key to selecting the right tool and achieving precise, repeatable results.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Materials Science & R&D | Sintering ceramics, metallic powders, composites |

| Battery Development | Anode/cathode material heat treatment for lithium-ion batteries |

| Medical & Aerospace | Annealing titanium alloys, heat-treating specialty steels |

| High-Purity Brazing | Joining reactive or dissimilar metals with clean, strong bonds |

Ready to enhance your lab's capabilities with precise atmospheric control? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum muffle furnaces can deliver superior purity and performance for your specific applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas