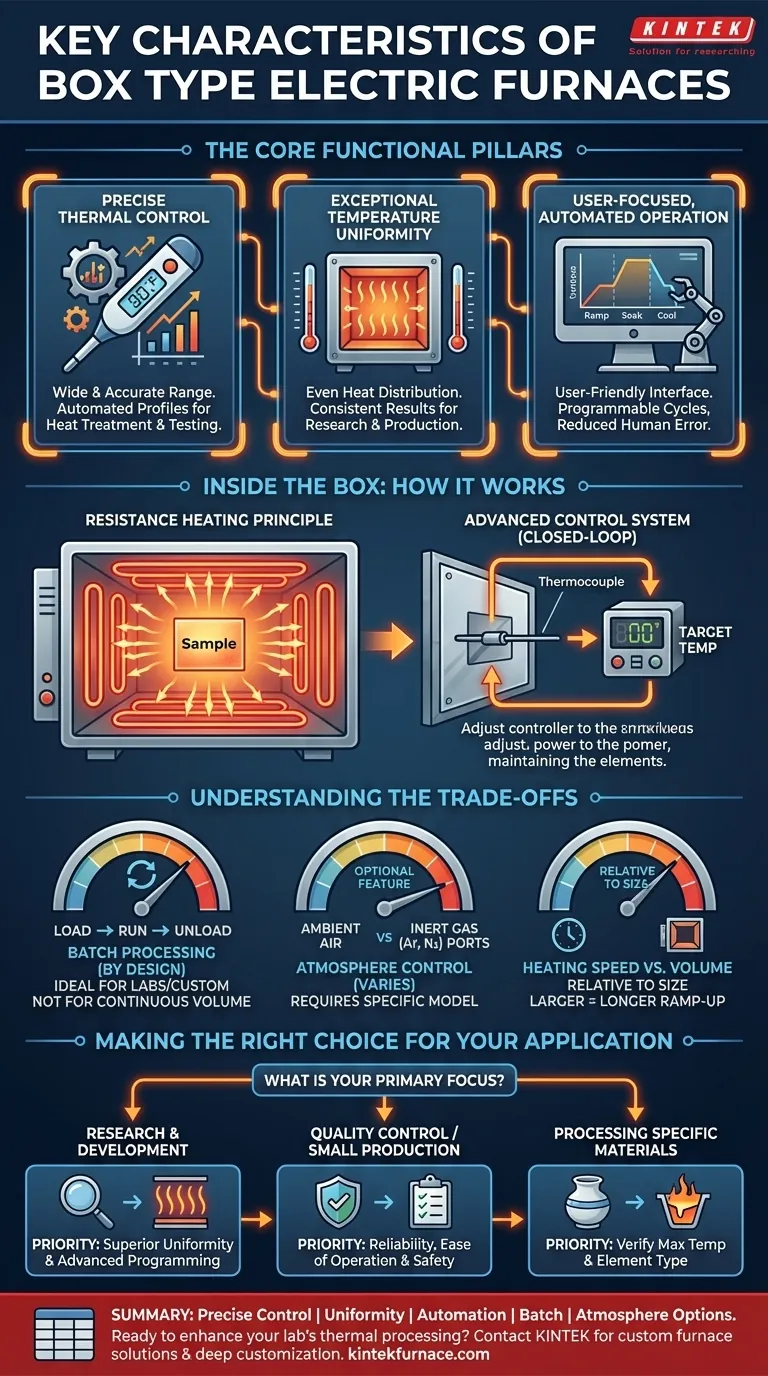

At their core, box-type electric furnaces are defined by three primary characteristics: a wide and precisely controllable temperature range, excellent temperature uniformity throughout the chamber, and straightforward, automated operation. These furnaces are designed as versatile tools for laboratory experiments and small-scale industrial processes, providing a highly controlled thermal environment for materials.

A box furnace is not simply a hot box; it is an instrument of precision. Its value lies in its ability to execute specific, repeatable thermal profiles, making it an indispensable tool for material science, quality control, and specialized manufacturing where thermal consistency is paramount.

The Core Functional Pillars

To understand if a box furnace is the right tool for your task, you must understand its fundamental capabilities. These furnaces are built around providing a stable, predictable, and easy-to-manage heating environment.

Precise Thermal Control & High Temperatures

Box furnaces offer a broad operating temperature range, making them suitable for a diverse array of processes from drying and curing to sintering and melting.

Their primary strength is the high accuracy of their temperature control systems. This allows users to program and automatically maintain specific temperatures, which is critical for heat treatment and material testing.

Exceptional Temperature Uniformity

Advanced heating technology and control systems ensure a uniform temperature distribution across the entire internal chamber.

This temperature uniformity is crucial for research and production. It guarantees that every part of a sample or batch is subjected to the exact same thermal conditions, leading to consistent and repeatable results.

User-Focused, Automated Operation

Modern box furnaces feature user-friendly digital interfaces that simplify complex heating schedules.

Operators can easily program multi-step temperature ramps, soaks, and cooling cycles. This automation reduces the chance of human error and ensures process consistency.

How a Box Furnace Achieves This Performance

The performance of a box furnace is not magic; it is the result of specific engineering choices in its heating and control mechanisms. Understanding these principles helps in evaluating different models.

The Principle of Resistance Heating

The heat source is typically an array of heating elements, such as resistance wires or plates.

When an electric current is passed through these elements, their natural resistance causes them to generate intense, radiant heat, which then fills the insulated chamber. Different element materials (like graphite or specialized alloys) are used to achieve different maximum temperatures.

The Role of Advanced Control Systems

The furnace achieves high accuracy through a closed-loop system. A thermocouple measures the internal temperature and feeds this data back to a digital controller.

The controller then adjusts the power sent to the heating elements to precisely match the user's programmed temperature profile, ensuring stability and accuracy.

Understanding the Trade-offs

No single piece of equipment is perfect for every job. Acknowledging the inherent limitations of a box furnace is key to making an informed decision.

Batch Processing by Design

The fundamental "box" design means these furnaces operate on a batch basis. You load material, run a cycle, and unload it.

This makes them ideal for labs and custom production but unsuitable for continuous, high-volume manufacturing, where a tunnel or conveyor furnace would be necessary.

Atmosphere Control Varies

While some advanced models offer excellent atmosphere control with ports for inert gases like argon or nitrogen, this is not a standard feature.

Basic models operate with ambient air. If your process is sensitive to oxygen, you must ensure you select a furnace specifically designed with gas-purging capabilities.

Heating Speed vs. Chamber Volume

The "fast heating speed" mentioned for box furnaces is relative to their size and class. They are designed to heat an entire insulated volume.

While efficient, they will not heat as rapidly as more targeted methods like induction or laser heating. Larger furnaces will naturally have longer ramp-up times than smaller lab units.

Making the Right Choice for Your Application

Your specific goal will determine which characteristics of a box furnace are most important.

- If your primary focus is research and development: Prioritize superior temperature uniformity and advanced programming controls for repeatable experimental results.

- If your primary focus is quality control or small-scale production: Emphasize reliability, ease of operation, and safety features to ensure consistent output with minimal operator training.

- If your primary focus is processing specific materials: Verify the furnace's maximum temperature and heating element type are suitable for your target application, whether it's sintering ceramics, annealing metals, or melting glass.

Ultimately, selecting the right box furnace comes from clearly defining your process needs and matching them to the specific capabilities of the equipment.

Summary Table:

| Characteristic | Description |

|---|---|

| Precise Thermal Control | Wide temperature range with high accuracy for automated heating profiles. |

| Temperature Uniformity | Even heat distribution across the chamber for consistent results. |

| Automated Operation | User-friendly digital interfaces for easy programming and reduced errors. |

| Batch Processing | Ideal for labs and custom production, not continuous high-volume use. |

| Atmosphere Control | Available in models with gas-purging for oxygen-sensitive processes. |

Ready to enhance your lab's thermal processing with a custom box furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether for material science, quality control, or specialized manufacturing, we deliver reliable, tailored equipment for consistent results. Contact us today to discuss how we can optimize your processes!

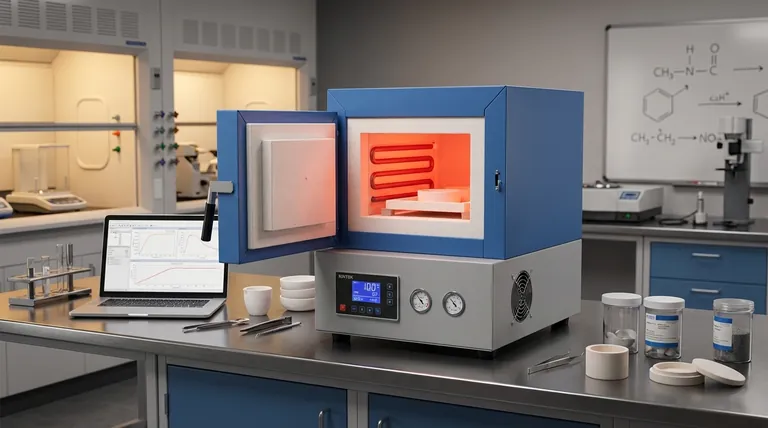

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics