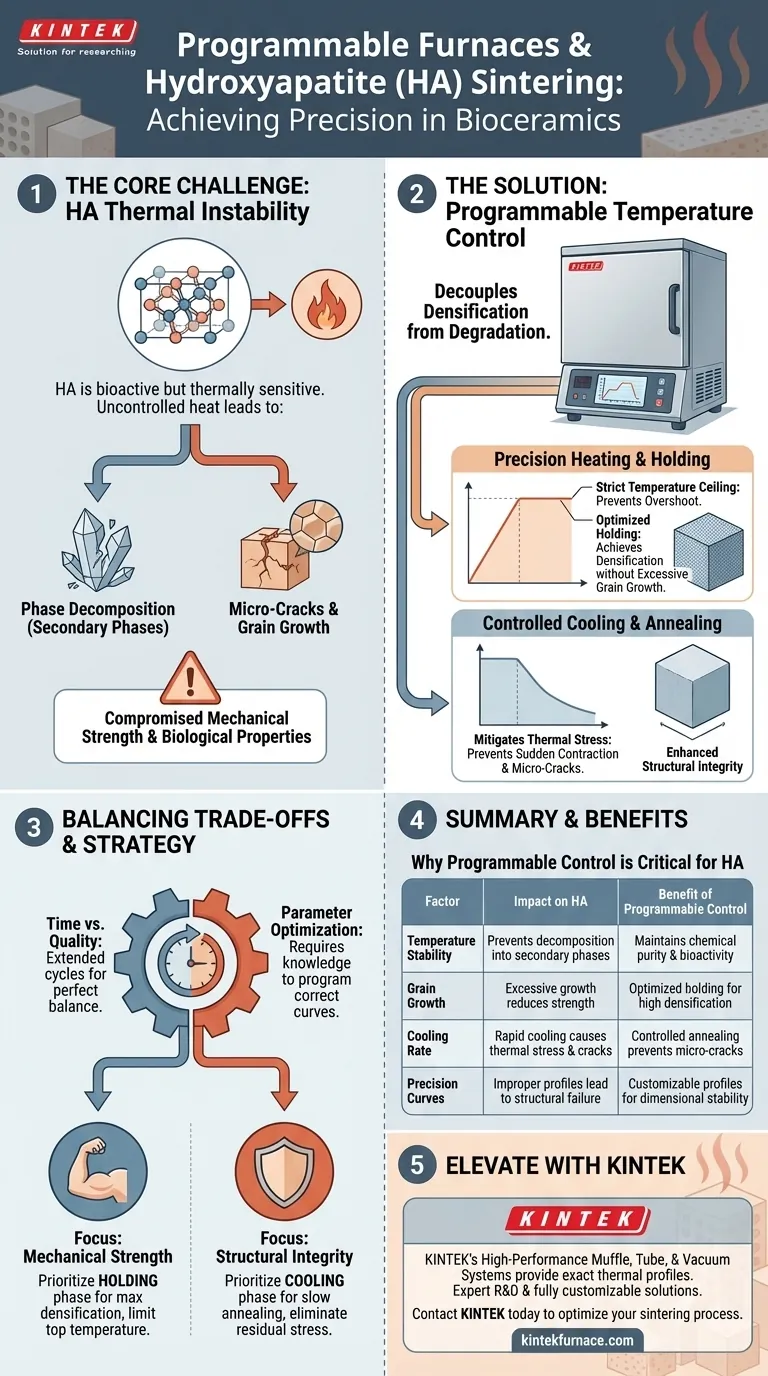

A programmable temperature control furnace is strictly necessary for sintering Hydroxyapatite (HA) because this material is chemically unstable and prone to phase decomposition at high temperatures. These furnaces provide the capability to set exact heating, holding, and cooling rates, which is the only way to achieve material densification without destroying the chemical structure or causing the ceramic to crack.

The core value of a programmable furnace is its ability to decouple densification from degradation. It allows you to reach the temperatures required to solidify the ceramic while actively preventing the micro-cracks and grain growth that compromise mechanical strength.

The Critical Role of Thermal Precision

Preventing Phase Decomposition

Hydroxyapatite (HA) is bioactive, but it is also thermally sensitive. The primary reference indicates that HA is prone to phase decomposition when exposed to uncontrolled high temperatures.

If the temperature overshoots or fluctuates, the HA breaks down into secondary phases (like tricalcium phosphate), altering its biological and mechanical properties. A programmable furnace eliminates this risk by adhering to a strict temperature ceiling.

Balancing Densification and Grain Growth

To make a ceramic block strong, you must achieve densification—closing the pores between particles. However, the heat required to do this also promotes excessive grain growth, which weakens the material.

A programmable furnace allows for specific "holding" times. This precise control ensures the material becomes dense enough for structural use but stops the heating process before the grains grow too large, optimizing the mechanical strength and dielectric response.

Managing Structural Integrity via Annealing

Mitigating Thermal Stress

Ceramics are brittle and poor conductors of heat. Rapid temperature changes cause thermal stress, leading to immediate failure or latent defects.

Programmable furnaces manage the cooling rate just as precisely as the heating rate. This controlled cooling process prevents the sudden contraction that snaps ceramic bonds.

The Importance of Annealing

The cooling phase in these furnaces acts as an annealing process. As noted in the supplementary references, this controlled decline in temperature mitigates residual stresses caused by thermal expansion.

By slowly lowering the temperature according to a preset curve, the furnace prevents micro-cracks caused by thermal shock. This ensures the final block maintains dimensional stability and high fracture toughness.

Understanding the Trade-offs

The Balance of Time vs. Quality

Using a programmable furnace introduces a complex variable: time. To achieve the perfect balance of density and grain size, sintering cycles often require extended holding and cooling periods.

Complexity of Parameter Optimization

While the furnace allows for precision, it does not guarantee it automatically. The operator must understand the material science well enough to program the correct curves.

A curve that heats too slowly may result in incomplete sintering, while a curve that cools too quickly renders the part structurally unsound. The hardware is only as effective as the thermal profile programmed into it.

Making the Right Choice for Your Goal

To maximize the utility of a programmable furnace for HA sintering, align your programming strategy with your end-use requirements:

- If your primary focus is Mechanical Strength: Prioritize the "holding" phase of the program to maximize densification while strictly limiting the top temperature to inhibit grain growth.

- If your primary focus is Structural Integrity: Focus on the "cooling" phase, programming a slow, elongated annealing curve to eliminate residual stress and prevent micro-cracking.

Precision in sintering is not a luxury for Hydroxyapatite; it is the defining factor between a usable bioceramic and a failed sample.

Summary Table:

| Factor | Impact on Hydroxyapatite (HA) | Benefit of Programmable Control |

|---|---|---|

| Temperature Stability | Prevents phase decomposition into secondary phases | Maintains chemical purity and bioactivity |

| Grain Growth | Excessive growth reduces material strength | Optimized holding times for high densification |

| Cooling Rate | Rapid cooling causes thermal stress and cracks | Controlled annealing prevents micro-cracks |

| Precision Curves | Improper profiles lead to structural failure | Customizable heating/cooling for dimensional stability |

Elevate Your Bioceramic Precision with KINTEK

Don't compromise the bioactivity or strength of your Hydroxyapatite samples. KINTEK’s high-performance Muffle, Tube, and Vacuum furnace systems provide the exact programmable thermal profiles required to eliminate phase decomposition and thermal stress.

Backed by expert R&D and precision manufacturing, our systems are fully customizable to meet the unique needs of lab researchers and medical manufacturers alike. Contact KINTEK today to discover how our advanced heating solutions can optimize your sintering process and guarantee superior material performance.

Visual Guide

References

- Liviu Duta, Valentina Grumezescu. The Effect of Doping on the Electrical and Dielectric Properties of Hydroxyapatite for Medical Applications: From Powders to Thin Films. DOI: 10.3390/ma17030640

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a high-temperature box furnace in Cu-Ni-P alloy annealing? Optimize Your Cold Rolling Results

- What is the primary purpose of using a muffle furnace for Bi5O7NO3 synthesis? Master Phase & Thermal Transformation

- What principles do muffle furnaces operate on? Master Heat, Isolation, and Uniform Transfer

- Why is annealing in a 600 Celsius muffle furnace critical for ZnCo2O4? Unlock High-Performance Spinel Catalysts

- How are modern box furnaces controlled? Discover Precision with Digital PID Systems

- How does a laboratory muffle furnace contribute to the transformation of biomass into carbon precursors? Expert Guide

- What are the typical specifications for lab box furnaces? Find Your Perfect Fit for Materials Processing

- What function does a water-cooling system serve in muffle furnaces? Stability & Precision Secrets Revealed