In high-precision muffle furnaces, a water-cooling system functions primarily as a thermal stabilizer. It acts as a "constant temperature wall interface" that maintains the structural integrity of the furnace shell and critical connection points. Beyond mere safety, this cooling layer creates a stable external boundary condition, which is essential for the internal control system to achieve accurate thermal compensation.

Core Takeaway While standard laboratory furnaces often rely on simple exhaust fans, high-precision units utilize water cooling to establish a fixed thermal boundary. This prevents shell deformation and provides the consistent baseline required for ultra-precise internal temperature regulation.

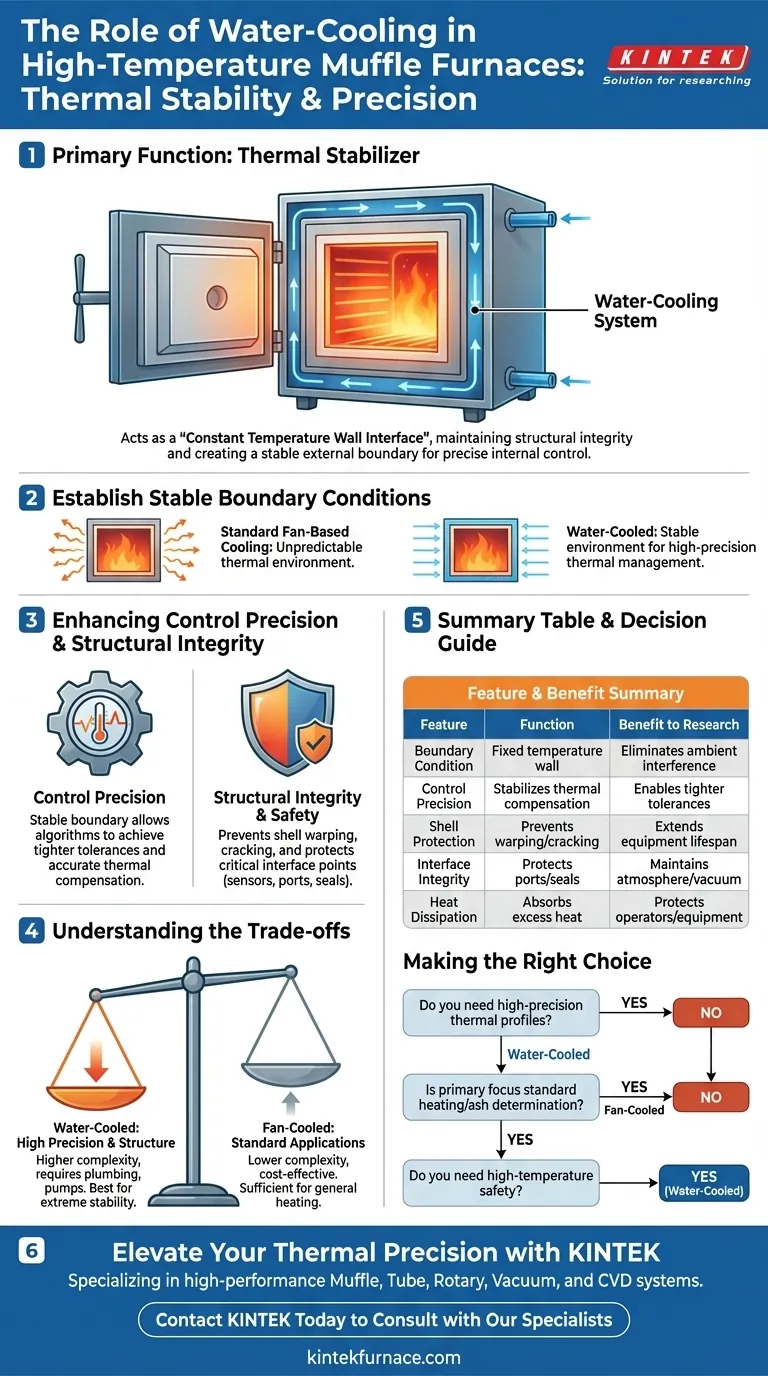

The Role of the Constant Temperature Wall

Establishing Stable Boundary Conditions

High-temperature operations create massive thermal gradients. The water-cooling system creates a consistent "wall" around the furnace chamber.

By keeping the external boundary at a fixed temperature, the system eliminates variables caused by fluctuating ambient conditions. This stability is the foundation for high-precision thermal management.

Enhancing Control Precision

Internal temperature control systems rely on algorithms to manage heat flow. These algorithms perform better when the external environment is predictable.

The water-cooling system assists the controller by stabilizing the environment against which it must compensate. This allows for tighter tolerances and more accurate thermal compensation during complex heating cycles.

Structural Integrity and Safety

Protecting the Furnace Shell

The immense heat generated inside a muffle furnace can compromise the outer casing. The primary physical role of the water-cooling system is to preserve the furnace shell.

By absorbing and removing excess heat, it prevents the casing from warping, cracking, or degrading over time. This ensures the unit remains mechanically sound even during prolonged high-temperature use.

Managing Specific Interfaces

Furnaces have critical interface points, such as ports for sensors, gas lines, or viewports. These areas are often more sensitive to thermal expansion than the main body.

Water cooling creates a protective thermal barrier around these specific interfaces. This prevents seal failure and maintains vacuum or atmosphere integrity within the muffle.

Understanding the Trade-offs

Complexity vs. Necessity

It is important to note that not all muffle furnaces require this level of thermal management. As noted in standard laboratory contexts, many units operate effectively with simple fan-based exhaust systems.

Water cooling adds complexity, requiring plumbing, pumps, and potential leak maintenance. It is a feature specifically designed for applications where structural rigidity and extremely precise temperature control outweigh the added operational overhead.

Making the Right Choice for Your Application

To determine if a water-cooled system is necessary for your specific requirements, consider the following:

- If your primary focus is high-precision thermal profiles: You likely need a water-cooled unit to ensure the control algorithms have a stable boundary condition for accurate compensation.

- If your primary focus is standard ash determination or general heating: A standard laboratory unit with fan-based cooling is typically sufficient and more cost-effective.

- If your primary focus is high-temperature safety: Water cooling provides the highest level of protection for the furnace shell and the operator by keeping external surface temperatures low.

The value of a water-cooling system lies not just in cooling, but in the rigorous control and stability it brings to high-temperature environments.

Summary Table:

| Feature | Function in Water-Cooled Muffle Furnaces | Benefit to Research/Production |

|---|---|---|

| Boundary Condition | Establishes a fixed temperature wall | Eliminates ambient temperature interference |

| Control Precision | Stabilizes thermal compensation environment | Enables tighter tolerances for complex cycles |

| Shell Protection | Prevents casing warping and cracking | Extends equipment lifespan and ensures safety |

| Interface Integrity | Protects sensor ports and gas line seals | Maintains atmosphere and vacuum stability |

| Heat Dissipation | Absorbs and removes excess external heat | Protects operators and sensitive lab equipment |

Elevate Your Thermal Precision with KINTEK

Don’t let fluctuating boundary conditions compromise your high-precision research. At KINTEK, we specialize in engineering high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the most rigorous laboratory standards. Whether you need a water-cooled furnace for ultra-stable thermal profiles or a custom-built solution for unique industrial applications, our expert R&D and manufacturing teams are here to deliver.

Ready to optimize your high-temperature processes? Contact KINTEK Today to Consult with Our Specialists

Visual Guide

References

- Yuchen Wang, Haisheng Fang. Research and optimization of temperature uniformity of high-precision muffle furnace. DOI: 10.1088/1742-6596/3009/1/012076

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the thermal insulation material categories for muffle furnaces? Choose the Best for Your Lab

- What materials are commonly used in the construction of a muffle furnace? Discover Durable Components for High-Temp Labs

- What emergency preparedness measures should be in place for muffle furnace operation? Ensure Lab Safety with Proactive Protocols

- What are the advantages of energy efficiency and rapid heating/cooling in digital muffle furnaces? Boost Lab Productivity and Cut Costs

- What is the function of high-temperature furnaces in biogenic hydroxyapatite conversion? Achieve High-Purity Biomaterials

- Why use a high-temp sintering furnace at 750°C for silver nanoparticles? Achieve purity and stability.

- What are the primary applications of a box furnace? Essential Uses in Heat Treatment and Material Processing

- What are the placement requirements for a muffle furnace? Ensure Safety and Performance in Your Lab