At its core, a box furnace is a versatile piece of thermal processing equipment designed for batch applications. Its primary uses revolve around subjecting materials to a controlled, high-temperature environment to alter their physical or chemical properties through processes like heat treatment, sintering, calcination, and sample preparation for analysis.

The true value of a box furnace lies in its simplicity and reliability. It serves as a general-purpose workhorse for labs and industries that need to heat materials in discrete batches within a stable, uniform thermal environment.

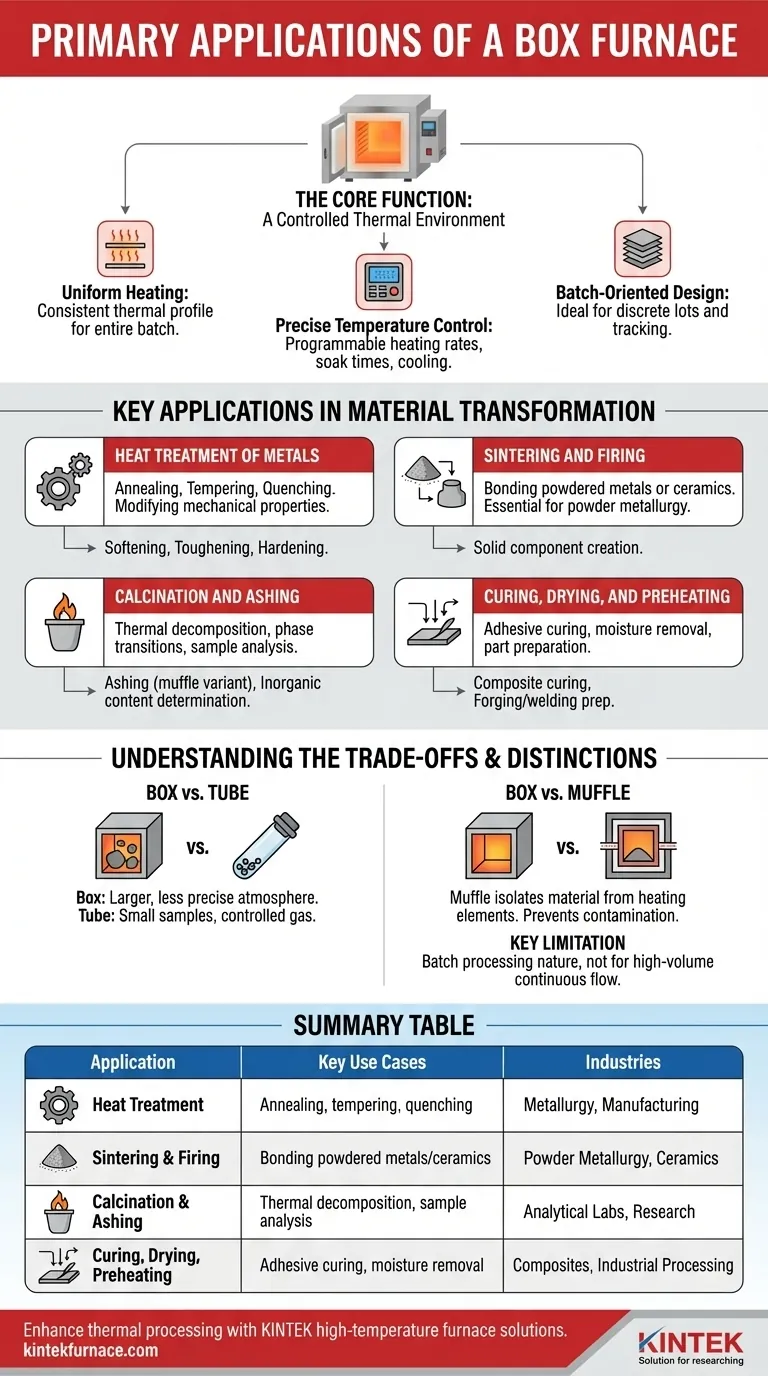

The Core Function: A Controlled Thermal Environment

The applications of a box furnace are a direct result of its fundamental design. Its structure is optimized to create a repeatable and uniform heating zone for materials processed in batches.

Uniform Heating

A box furnace's chamber, combined with strategically placed heating elements (often electric), is designed to distribute heat evenly. This ensures that an entire batch of material experiences the same thermal profile, which is critical for consistent results.

Precise Temperature Control

Modern box furnaces are equipped with sophisticated temperature control systems. These systems allow operators to program specific heating rates, soak times at peak temperature, and cooling profiles, enabling highly repeatable and documented processes.

Batch-Oriented Design

Unlike a continuous or conveyor furnace, a box furnace is designed for batch processing. Materials are placed inside, the door is closed, the thermal cycle is run, and the materials are removed. This makes it ideal for research, small-scale production, and processes where individual lots must be tracked.

Key Applications in Material Transformation

The controlled environment of a box furnace makes it suitable for a wide range of thermal processes across industries from metallurgy to materials science.

Heat Treatment of Metals

This is one of the most common applications. Processes like annealing (softening), tempering (increasing toughness), and quenching (hardening) are used to precisely modify the mechanical properties of steel and other metal parts.

Sintering and Firing

Box furnaces are essential for creating solid components from powders. In sintering, powdered metals or ceramics are heated below their melting point until their particles bond together. This is fundamental to powder metallurgy and advanced ceramics manufacturing.

Calcination and Ashing

Calcination uses heat to cause thermal decomposition, phase transitions, or the removal of a volatile fraction from a material. In analytical labs, a box furnace (often a muffle furnace variant) is used for ashing, which involves burning off organic substances to determine the inorganic content of a sample.

Curing, Drying, and Preheating

Many industrial processes require a preliminary heating step. Box furnaces are used for curing adhesives and composites, drying materials to remove moisture, and preheating parts before subsequent steps like forging or welding.

Understanding the Trade-offs and Distinctions

While versatile, a box furnace is not the universal solution for all heating tasks. Understanding its relationship to other furnace types is key to selecting the right tool.

Box Furnace vs. Tube Furnace

A tube furnace uses a cylindrical tube as its heating chamber, which is ideal for processing small samples or for applications requiring a tightly controlled gas atmosphere. Box furnaces handle larger or irregularly shaped objects more easily but may offer less precise atmosphere control than a dedicated tube furnace.

Box Furnace vs. Muffle Furnace

This is a common point of confusion. A muffle furnace contains an inner chamber (the "muffle") that isolates the material from direct contact with the heating elements. This prevents contamination. Many modern box furnaces are built as muffle furnaces, but the terms are not strictly interchangeable. If preventing contamination from the heating elements is critical, you specifically need a muffle furnace.

Key Limitations

The primary limitation is its batch-processing nature. It is not efficient for high-volume, continuous manufacturing where a conveyor or belt furnace would be superior. While some models offer atmosphere control, they may not achieve the purity levels of more specialized systems.

Making the Right Choice for Your Goal

Selecting the correct furnace depends entirely on your material, desired outcome, and production scale.

- If your primary focus is general-purpose heat treatment of metal parts: A standard box furnace is the industry-standard choice for its reliability and uniform heating.

- If your primary focus is creating ceramic or powdered metal parts: A high-temperature box furnace designed for sintering is the correct tool.

- If your primary focus is analytical sample preparation like ashing: You specifically need a box-style muffle furnace to prevent sample contamination.

- If your primary focus is high-purity crystal growth or processing in a specific gas: A tube furnace is likely a more suitable and precise instrument for your needs.

Ultimately, the box furnace is a foundational tool, providing the simple, powerful, and controlled application of heat required for countless material innovations.

Summary Table:

| Application | Key Use Cases | Industries |

|---|---|---|

| Heat Treatment | Annealing, tempering, quenching of metals | Metallurgy, Manufacturing |

| Sintering and Firing | Bonding powdered metals or ceramics | Powder Metallurgy, Ceramics |

| Calcination and Ashing | Thermal decomposition, sample analysis | Analytical Labs, Research |

| Curing, Drying, Preheating | Adhesive curing, moisture removal, part preparation | Composites, Industrial Processing |

Ready to enhance your thermal processing with a reliable box furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in metallurgy, materials science, or analytical research, we can tailor a solution for your batch processing needs. Contact us today to discuss how our furnaces can boost your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency