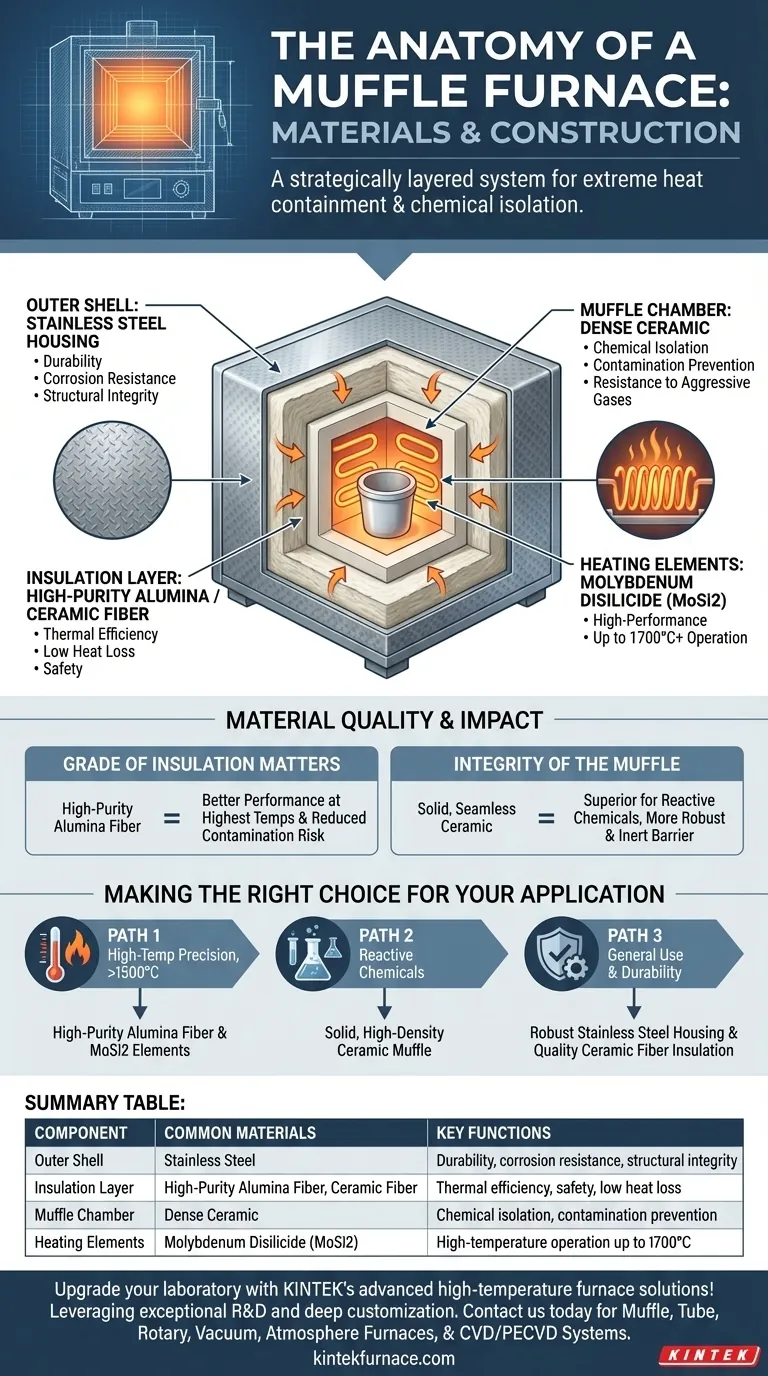

At its core, a muffle furnace is a strategically layered system of specialized materials designed for extreme heat containment and chemical isolation. The most common components are a durable stainless steel housing, high-purity alumina or ceramic fiber insulation, and an inner ceramic muffle that holds the sample, all heated by powerful electric elements.

The construction of a muffle furnace is not about a single "best" material, but about the synergy between different materials. Each component—from the outer shell to the inner chamber—is chosen for a specific function, and their collective quality dictates the furnace's thermal efficiency, durability, and a ability to protect your samples.

The Anatomy of a Muffle Furnace: A Material-by-Material Breakdown

A muffle furnace is more than just a hot box. Its performance hinges on how three critical zones are constructed: the external structure, the insulation, and the internal chamber.

The Outer Shell: For Structural Integrity and Protection

The housing of a muffle furnace serves as its first line of defense against the laboratory environment and provides the necessary structural rigidity.

It is typically constructed from textured stainless steel sheets or other rugged steel. This choice prioritizes durability and corrosion resistance, which are essential for longevity in potentially harsh lab conditions.

The Insulation Layer: The Key to Thermal Efficiency and Safety

The most critical material for performance is the insulation, which is responsible for containing extreme temperatures, ensuring energy efficiency, and keeping the outer shell cool.

High-end furnaces use a double-layer shell structure packed with advanced insulation. The most common materials are high-purity alumina fiber and high-density ceramic fiber.

These materials are chosen for their exceptionally low thermal conductivity, meaning they are excellent at preventing heat from escaping. They are also lightweight, fire-resistant, and can offer electrical insulation at very high temperatures.

The Muffle Chamber: Isolating the Sample

The "muffle" is the inner chamber that isolates the workload from the heating elements. This separation is crucial for preventing contamination and creating a controlled atmosphere.

This chamber is almost always made of a dense ceramic material. Ceramic muffles provide outstanding resistance to aggressive gases and chemical vapors that might be released from a sample during heating.

The Heating Elements: The Engine of the Furnace

The heat itself is generated by high-performance electric heating elements designed to withstand and produce extreme temperatures reliably.

While specifications vary, these are often advanced components like molybdenum disilicide (MoSi2) elements, which are capable of operating efficiently at temperatures up to 1700°C or higher.

Understanding Material Quality and Its Impact

Not all furnaces are built alike, and the quality of the materials used is the primary differentiator between a standard model and a high-performance one.

The Grade of Insulation Matters

The term "ceramic fiber" can be broad. Look for specifications that mention high-purity alumina fiber. Higher purity translates to better performance at the highest temperature ranges and reduces the risk of the insulation itself becoming a source of contamination.

The Integrity of the Muffle

A solid, seamless ceramic muffle is superior for applications involving reactive chemicals. It provides a more robust and chemically inert barrier compared to chambers that are simply lined with fiber insulation, which can degrade or trap contaminants over time.

The Importance of System Design

The best furnaces utilize a graded insulation package, meaning different types and densities of insulation are used in different areas to optimize performance. This, combined with a well-sealed, hinged door insulated with fiber materials, minimizes heat loss and ensures temperature uniformity.

Making the Right Choice for Your Application

Selecting the right furnace means matching its material composition to your intended work.

- If your primary focus is high-temperature precision (above 1500°C): Look for furnaces with high-purity alumina fiber insulation and specified high-performance heating elements like MoSi2.

- If your primary focus is working with reactive chemicals: Prioritize a model with a solid, high-density ceramic muffle to ensure sample integrity and chamber longevity.

- If your primary focus is general use and long-term durability: A robust stainless steel housing and a double-walled structure with quality ceramic fiber insulation are your most important markers.

Ultimately, understanding the function of each material empowers you to select a furnace that is truly engineered for your specific goals.

Summary Table:

| Component | Common Materials | Key Functions |

|---|---|---|

| Outer Shell | Stainless Steel | Durability, corrosion resistance, structural integrity |

| Insulation Layer | High-Purity Alumina Fiber, Ceramic Fiber | Thermal efficiency, safety, low heat loss |

| Muffle Chamber | Dense Ceramic | Chemical isolation, contamination prevention |

| Heating Elements | Molybdenum Disilicide (MoSi2) | High-temperature operation up to 1700°C |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific applications!

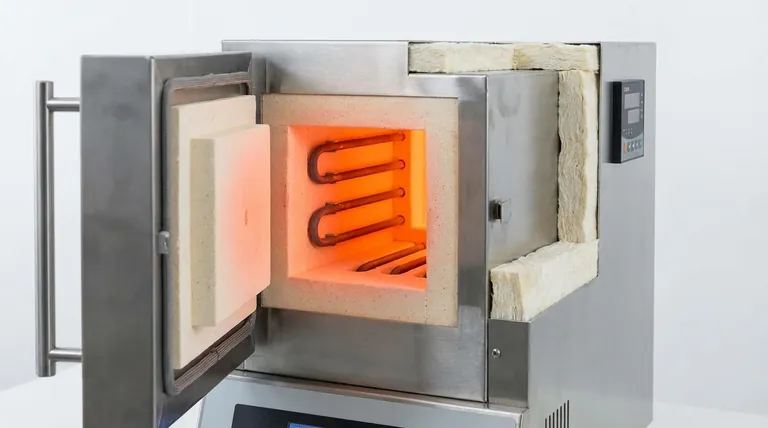

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals