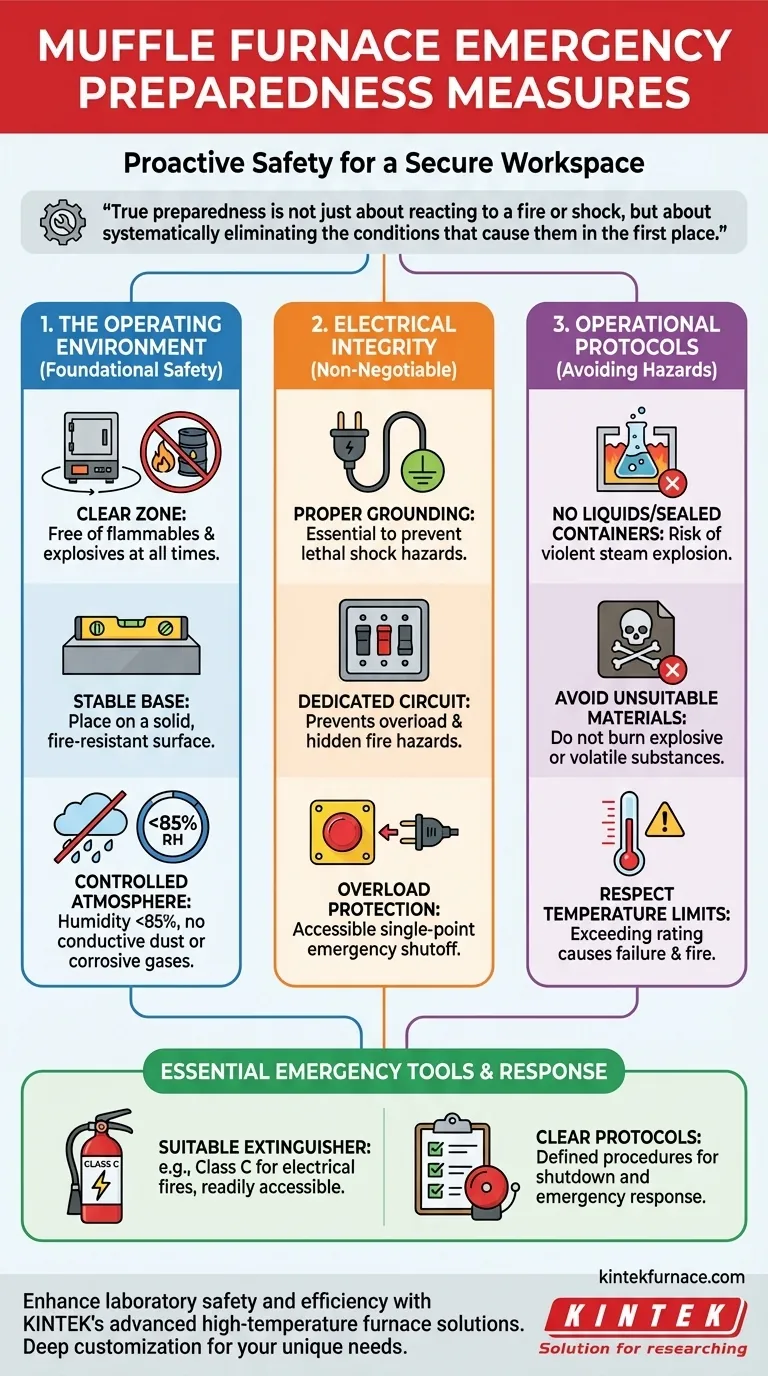

To ensure safety, your emergency preparedness must focus on three core areas: the immediate environment, the electrical supply, and clear operational protocols. You must have a suitable fire extinguisher readily accessible, maintain a clear zone free of all flammable and explosive materials around the furnace, and ensure the unit is properly grounded on a dedicated electrical circuit. This proactive approach is the foundation of safe muffle furnace operation.

The most effective emergency plan for a muffle furnace is one you never have to use. True preparedness is not just about reacting to a fire or shock, but about systematically eliminating the conditions that cause them in the first place.

Foundational Safety: The Operating Environment

An emergency often begins with a flaw in the workspace. Controlling the furnace's immediate environment is your first and most critical line of defense against accidents.

Eliminating Fire Hazards

A muffle furnace radiates intense heat. Any flammable or explosive materials stored nearby, including liquids, papers, or chemicals, pose a significant fire risk.

Ensure a designated clear zone is maintained around the furnace at all times. This isn't a one-time setup; it requires constant vigilance to prevent clutter from accumulating.

Controlling Atmospheric Risks

The air itself can become a hazard. The environment must have a relative humidity below 85% and be free of conductive dust, corrosive gases, and explosive fumes.

High humidity or conductive dust can lead to electrical short-circuits, creating both a shock and fire risk. Corrosive gases can degrade furnace components and wiring over time, leading to unexpected failure.

Ensuring Physical Stability

The furnace must be placed on a solid, level, and fire-resistant surface. An unstable base could cause the unit to tip, potentially spilling extremely hot contents or damaging the internal elements.

Electrical Integrity: A Non-Negotiable

Electrical failures are a primary source of furnace-related emergencies, ranging from electric shock to catastrophic fires. Proper electrical installation is not optional.

The Critical Role of Grounding

Proper grounding is arguably the most important electrical safety feature. It ensures that if a fault occurs, the electrical current has a safe path to the earth, tripping a breaker instead of energizing the furnace's metal casing.

An ungrounded furnace can become a lethal shock hazard without any visible warning.

Dedicated Power and Overload Protection

A muffle furnace should always be powered by a dedicated circuit with its own controller or breaker, often referred to as an "electric gate."

Plugging it into a shared circuit can cause an overload, overheating the building's wiring and creating a serious, hidden fire hazard inside the walls. The dedicated controller also provides a clear, single point of emergency power shutoff.

Common Pitfalls and Operational Hazards

Many emergencies are caused by operator error or a misunderstanding of how materials behave at extreme temperatures. Avoiding these common mistakes is a key part of preparedness.

The Danger of Liquids and Sealed Containers

Never place liquids or samples with high moisture content directly into a hot furnace. The water can flash into steam, expanding rapidly and causing a violent explosion that can destroy the chamber and eject hot material.

Similarly, never heat a sealed or airtight container. The internal pressure will build until the container fails explosively.

Processing Unsuitable Materials

Do not burn explosive, volatile, or dangerously reactive materials inside the furnace. The purpose of the furnace is high-temperature thermal processing, not incineration of hazardous goods.

Introducing prohibited materials can lead to fire, explosion, or the release of toxic fumes.

Respecting Temperature Limits

Every furnace has a maximum rated temperature. Exceeding this limit can cause the heating elements to fail, potentially leading to arcing, fire, or irreparable damage to the unit.

Making the Right Choice for Your Goal

Use this framework to guide your safety implementation based on your specific needs.

- If your primary focus is establishing a new workspace: Prioritize the infrastructure—a dedicated, properly grounded electrical circuit and a designated, non-combustible location.

- If your primary focus is training operators: Emphasize operational discipline—never heat liquids or sealed containers, always respect temperature limits, and know the emergency shutdown procedure.

- If your primary focus is auditing an existing setup: Verify the fundamentals—confirm the unit is grounded, check that the area is clear of flammables, and ensure a suitable fire extinguisher (e.g., Class C for electrical) is accessible and inspected.

Ultimately, a safe workspace is the direct result of a continuous and proactive safety culture.

Summary Table:

| Category | Key Measures |

|---|---|

| Environment | Clear zone free of flammables, stable fire-resistant surface, controlled humidity (<85%), no corrosive gases |

| Electrical | Proper grounding, dedicated circuit with overload protection, accessible emergency shutoff |

| Operations | No liquids or sealed containers, avoid explosive materials, respect temperature limits, regular training |

| Emergency Tools | Suitable fire extinguisher (e.g., Class C), clear protocols for shutdown and response |

Enhance your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability ensures precise fit for your experimental requirements, helping you maintain a secure and productive workspace. Contact us today to discuss how we can support your emergency preparedness and operational goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?