For correct and safe operation, a muffle furnace must be placed on a stable, level, and heat-resistant surface like a concrete platform. The electrical supply must be a dedicated, properly grounded circuit rated for the furnace's high power draw (e.g., 20A, 220VAC). Crucially, the external controller must be positioned away from the main furnace body to protect its sensitive electronic components from radiant heat and vibration.

Proper placement is not a matter of convenience; it is the foundational requirement for ensuring the safety of your personnel, the longevity of the equipment, and the accuracy of your results. Mishandling these steps can lead to fire hazards, equipment failure, and compromised work.

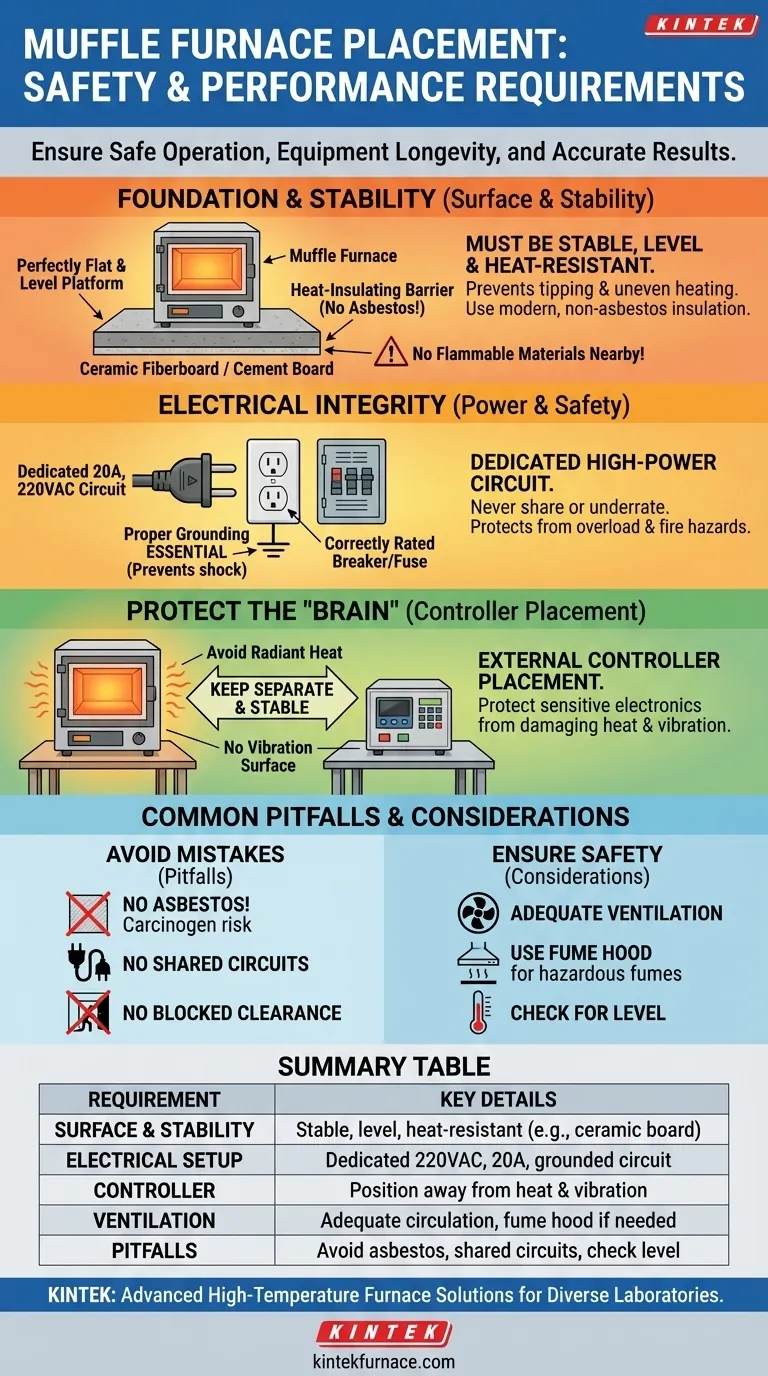

Foundational Requirements: Surface and Stability

The immense heat generated by a muffle furnace, which can exceed 1400°C, dictates its physical placement. The primary concerns are structural stability and heat management.

The Need for a Stable, Level Platform

A muffle furnace must be installed on a perfectly flat and stable surface, such as a dedicated concrete platform or sturdy workbench.

An uneven surface can cause the furnace door to seal improperly, leading to heat loss and temperature instability. More critically, an unstable base presents a tipping hazard, a catastrophic failure for an operating high-temperature device.

Managing Intense Heat Transfer

Even with high-grade insulation, a significant amount of heat radiates from the furnace's base. You must place a heat-insulating barrier between the furnace and the countertop.

Materials like a ceramic fiberboard or a cement board are excellent for this purpose. This prevents heat from damaging the underlying surface and mitigates a potential fire risk.

Electrical Integrity: Power and Safety

A muffle furnace is a high-power electrical appliance. Treating its electrical setup with the same diligence as its physical placement is non-negotiable for safety and performance.

Providing Dedicated, Sufficient Power

These furnaces typically require a dedicated single-phase, 220VAC circuit capable of handling at least 20 amps.

Attempting to run a furnace on an underrated or shared circuit will lead to tripped breakers and is a serious fire hazard due to the risk of overheating wires within the walls.

The Non-Negotiable Role of Grounding

Proper grounding is essential. A ground connection provides a safe path for electrical current to flow in the event of a short circuit, preventing the furnace's metal casing from becoming energized and protecting operators from severe electric shock.

Using Appropriate Fuses and Breakers

The electrical circuit must be protected by the correctly rated circuit breaker or fuse. This device acts as a fail-safe, protecting both the building's wiring from overload and the furnace's sensitive electronics from damaging power surges.

Protecting the "Brain": Controller Placement

The furnace's PID controller is its electronic brain, responsible for regulating temperature with high precision. This component is far more sensitive to the environment than the furnace chamber itself.

The Threat of Radiant Heat

Electronic components fail when they overheat. The controller must be placed far enough away from the furnace body that it is not exposed to significant radiant heat.

Failing to do so can cause erratic temperature control, inaccurate readings, and ultimately, premature failure of the controller, which is often an expensive repair.

The Impact of Vibration

The controller should be placed on a surface free from vibration. Constant shaking, even if minor, can loosen internal connections and damage delicate components over time, leading to reliability issues.

Common Pitfalls to Avoid

Beyond the core rules, experienced operators are mindful of several common mistakes that can compromise safety and performance.

The Asbestos Dilemma

Older manuals often recommend placing an asbestos board under the furnace. While effective as an insulator, asbestos is a known carcinogen and should not be used.

Modern, safer alternatives like ceramic fiberboard, high-density cement board, or fire bricks offer equivalent or superior heat protection without the health risks.

Neglecting Clearance and Ventilation

A muffle furnace needs "breathing room." Ensure there is adequate clearance on all sides to allow for air circulation, which helps dissipate ambient heat.

Furthermore, never place flammable materials near the furnace. Depending on what is being heated, samples can off-gas fumes, so the room must be well-ventilated. For applications with known hazardous fumes, the furnace should be operated under a fume hood.

Making the Right Choice for Your Setup

Use these guidelines to ensure a safe and effective installation tailored to your priorities.

- If your primary focus is operator safety and lab compliance: Prioritize a dedicated, grounded 20A circuit and the use of modern, non-asbestos insulating boards.

- If your primary focus is equipment longevity and accuracy: Emphasize the physical separation of the controller from the furnace body to protect it from heat and vibration.

- If your primary focus is a fast, error-free first use: Before powering on, systematically verify the stability of the platform, the heat resistance of the surface, and the integrity of the electrical connection.

Proper placement is the first and most critical step in ensuring your muffle furnace operates safely, accurately, and reliably for years to come.

Summary Table:

| Requirement | Key Details |

|---|---|

| Surface and Stability | Stable, level platform (e.g., concrete); use heat-resistant barriers like ceramic fiberboard |

| Electrical Setup | Dedicated 220VAC, 20A circuit; proper grounding and circuit protection |

| Controller Placement | Position away from furnace to avoid heat and vibration; ensure stable, cool environment |

| Ventilation and Clearance | Adequate air circulation; keep flammable materials away; use fume hood if needed |

| Common Pitfalls | Avoid asbestos; ensure no shared circuits; check for level installation |

Ensure your muffle furnace is installed correctly for maximum safety and efficiency! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today for expert guidance and tailored solutions that protect your equipment and enhance your lab's performance.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation