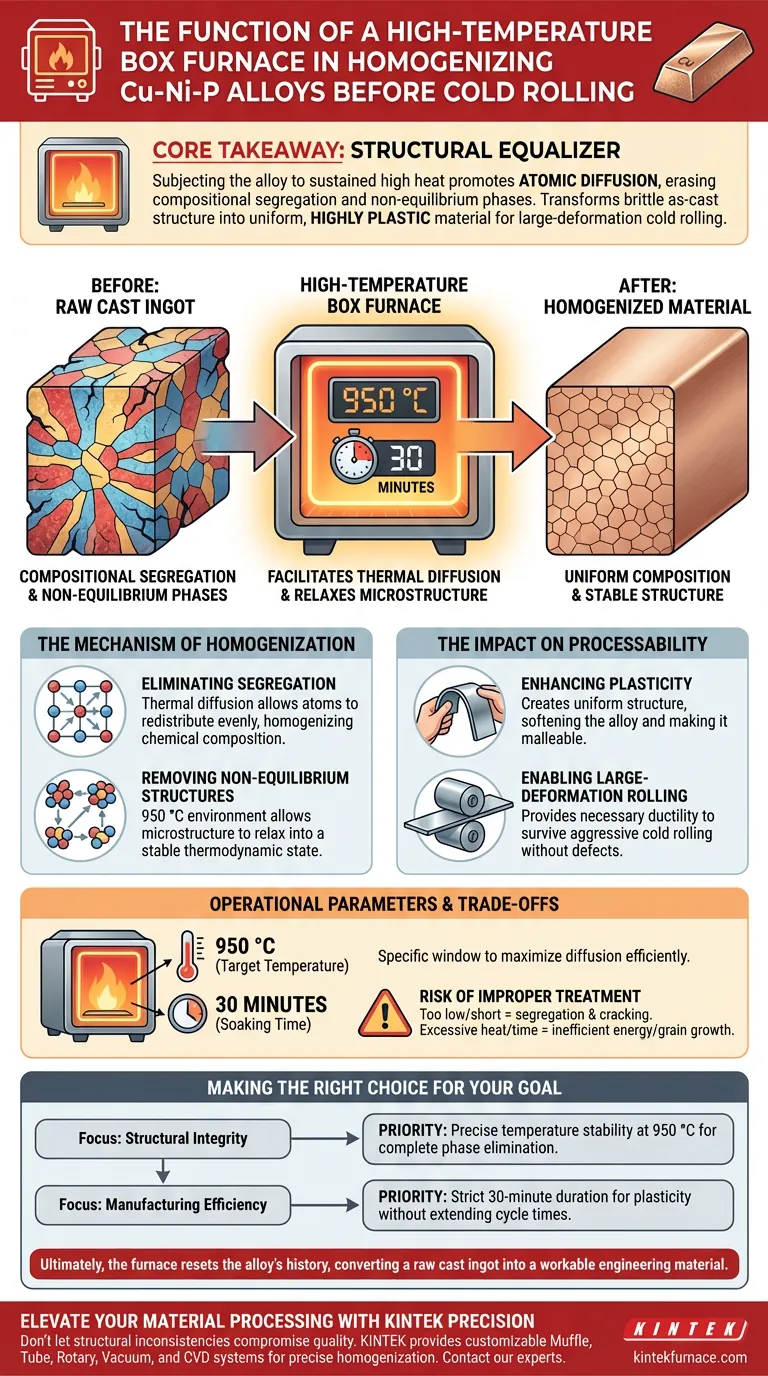

The primary function of a high-temperature box furnace during the homogenization annealing of Cu-Ni-P alloys is to facilitate thermal diffusion by maintaining a stable environment at approximately 950 °C. This critical thermal step eliminates the structural inconsistencies inherent in the cast ingot, directly preparing the material for the mechanical stress of manufacturing.

Core Takeaway The furnace acts as a structural equalizer. By subjecting the alloy to sustained high heat, it promotes atomic diffusion that erases compositional segregation and non-equilibrium phases. This transforms the brittle as-cast structure into a uniform, highly plastic material capable of withstanding large-deformation cold rolling without failure.

The Mechanism of Homogenization

Eliminating Compositional Segregation

When Cu-Ni-P alloys are first cast, the cooling process often results in segregation, where chemical elements are distributed unevenly throughout the ingot.

The high-temperature box furnace addresses this by holding the alloy at high heat. This energy triggers thermal diffusion, allowing atoms to migrate and redistribute evenly, effectively homogenizing the chemical composition.

Removing Non-Equilibrium Structures

Cast ingots frequently contain non-equilibrium structures—unstable phases formed during rapid solidification.

Exposure to the 950 °C environment allows the microstructure to relax and reorganize into a stable state. This thermodynamic equilibrium is essential for consistent material performance.

The Impact on Processability

Enhancing Material Plasticity

The most immediate operational goal of this treatment is to improve plasticity.

An inhomogeneous alloy is prone to cracking and brittleness. By creating a uniform internal structure, the furnace treatment significantly softens the alloy, making it more malleable.

Enabling Large-Deformation Rolling

Cold rolling involves compressing the metal to reduce thickness, which exerts immense physical stress on the atomic lattice.

Without the homogenization provided by the box furnace, the alloy would likely suffer from defects or fractures during large-deformation cold rolling. The furnace ensures the material has the ductility required to survive this aggressive processing step.

Operational Parameters and Trade-offs

Specific Processing Conditions

For Cu-Ni-P alloys, the standard protocol involves heating the material to 950 °C and maintaining this temperature for 30 minutes.

This specific time-temperature window is calculated to maximize diffusion without causing unnecessary delays or energy consumption.

The Risk of Improper Treatment

Precision in the furnace environment is critical.

If the temperature is too low or the duration too short, segregation remains, leading to non-uniform deformation or cracking during rolling. Conversely, excessive heat or time can lead to inefficient energy use or undesirable grain growth, though the primary goal remains the elimination of casting defects.

Making the Right Choice for Your Goal

To optimize your Cu-Ni-P alloy processing, ensure your furnace settings align with your specific downstream requirements:

- If your primary focus is Structural Integrity: Prioritize precise temperature stability at 950 °C to ensure complete elimination of brittle non-equilibrium phases before any mechanical stress is applied.

- If your primary focus is Manufacturing Efficiency: Adhere strictly to the 30-minute duration to achieve sufficient plasticity for cold rolling without extending cycle times unnecessarily.

Ultimately, the high-temperature box furnace is not just a heating device; it is the tool that resets the alloy's history, converting a raw cast ingot into a workable engineering material.

Summary Table:

| Process Parameter | Requirement | Role in Material Transformation |

|---|---|---|

| Target Temperature | 950 °C | Facilitates rapid atomic thermal diffusion |

| Soaking Time | 30 Minutes | Ensures removal of non-equilibrium phases |

| Primary Outcome | Uniform Composition | Erases chemical segregation from casting |

| Mechanical Impact | Enhanced Plasticity | Enables large-deformation cold rolling |

Elevate Your Material Processing with KINTEK Precision

Don’t let structural inconsistencies compromise your manufacturing quality. KINTEK provides industry-leading high-temperature box furnaces designed to deliver the precise thermal stability required for critical homogenization annealing. Backed by expert R&D and manufacturing, our range includes Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique metallurgical needs.

Ensure your alloys possess the plasticity and uniformity required for flawless cold rolling. Contact our technical experts today to discover how KINTEK’s advanced lab high-temp furnaces can optimize your R&D and production outcomes.

Visual Guide

References

- Wendi Yang, Jilin He. Microstructure and Texture Evolution of Cu-Ni-P Alloy after Cold Rolling and Annealing. DOI: 10.3390/ma17112696

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why was the muffle furnace initially developed? To Ensure Purity in High-Temperature Processing

- What is the main utility of the exhaust system in a muffle furnace? Safely Remove Hazardous Gases for Lab Safety

- Why is a laboratory high-temperature box furnace essential for KNN ceramic powders? Mastering Solid-State Synthesis

- How does a box furnace work? A Guide to Precise, Uniform Heat Treatment

- What is the role of a laboratory high-temperature furnace in LLZO crystal phase regulation? Optimize Li-Ion Electrolytes

- What are the environmental conditions for operating a muffle furnace and its controller? Ensure Safety and Accuracy

- How does heat treatment in a muffle furnace affect CuFe2O4–SnO2-rGO? Optimize Heterojunction Composite Performance

- What role does a high-precision high-temperature box furnace play in the controlled foaming of aluminum? Key Insights