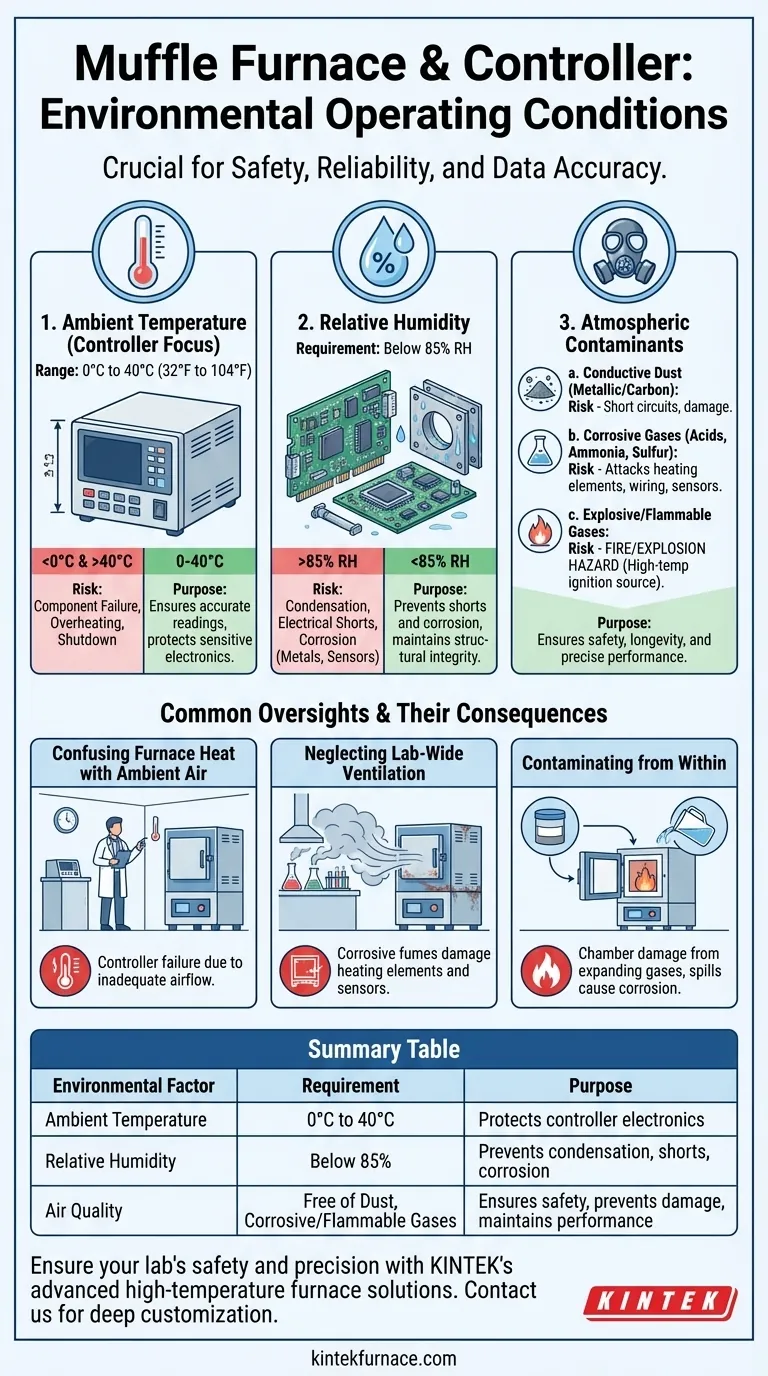

To ensure safe and reliable operation, a muffle furnace and its controller must be placed in a controlled environment. The key requirements are an ambient temperature between 0-40°C for the controller, relative humidity below 85%, and an atmosphere completely free of conductive dust, corrosive gases, and explosive or flammable materials.

Adhering to these environmental conditions is not a matter of optimization, but a fundamental requirement. Failure to do so risks electrical failure of the control unit, accelerated corrosion of the furnace, and presents a significant safety hazard to operators and the facility.

Deconstructing the Core Environmental Requirements

A muffle furnace is a precision instrument that combines high-power heating elements with sensitive electronic controls. Each environmental parameter is designed to protect a specific aspect of this system.

Ambient Temperature (0°C to 40°C)

This temperature range applies specifically to the furnace controller, not the furnace chamber itself. The controller contains microprocessors, relays, and other electronic components that are sensitive to temperature extremes.

Operating below 0°C can cause components to perform outside of their specified tolerances, leading to inaccurate temperature readings or control failure. Operating above 40°C can cause the electronics to overheat, significantly shortening their lifespan and risking a total system shutdown.

Relative Humidity (Below 85%)

High humidity poses a dual threat to the furnace system. First, it can lead to condensation on the controller's circuit boards, creating a direct path for electrical shorts.

Second, moisture accelerates the corrosion of the furnace's metal casing, structural components, and even the thermocouple sensor leads. This compromises the physical integrity of the unit and can lead to faulty temperature measurements.

Atmospheric Contaminants

The quality of the air surrounding the furnace is critical for both safety and longevity. The environment must be free from three primary types of airborne contaminants.

1. Conductive Dust: Metallic or carbon-based dust can settle on electronic circuit boards inside the controller. This creates unintended electrical pathways that can cause short circuits and permanent damage.

2. Corrosive Gases: Vapors from acids, ammonia, or sulfur compounds are highly destructive. They will aggressively attack the heating elements, thermocouple sensor, and internal wiring, leading to premature failure and inaccurate performance.

3. Explosive or Flammable Gases: This is the most acute safety risk. A muffle furnace operates at temperatures that can easily ignite flammable gases or vapors, potentially causing a fire or explosion. The workspace must be clear of these substances at all times.

Common Oversights and Their Consequences

Properly managing the environment requires more than just a casual check. Certain common mistakes can undermine the safety and reliability of your furnace.

Confusing Furnace Heat with Ambient Air

The furnace body radiates a significant amount of heat. It is a critical mistake to assume the room temperature is acceptable without measuring it near the controller. The controller must be situated where it receives adequate airflow to remain within its 0-40°C operating range.

Neglecting Lab-Wide Ventilation

A general-purpose lab may contain various chemicals. Ensure that your facility's ventilation system actively removes corrosive fumes from the air, rather than simply circulating them. The furnace should not be placed directly downstream from a fume hood or chemical storage area.

Contaminating the Furnace from Within

The operating environment includes the inside of the furnace chamber. Never place sealed containers or pour liquids directly into the furnace. Rapidly expanding gases can damage the chamber, and spills can release corrosive vapors and damage the insulation and heating elements.

Establishing an Optimal Operating Environment

Use these guidelines to ensure your setup is safe, reliable, and produces accurate results.

- If your primary focus is safety and longevity: Prioritize air quality by ensuring dedicated ventilation that removes corrosive and flammable fumes, and implement strict housekeeping to eliminate conductive dust.

- If your primary focus is data accuracy: Maintain a stable ambient temperature (well within the 0-40°C range) and low humidity around the controller to guarantee consistent electronic performance.

- If you are setting up a new furnace: Place the unit in a clean, dry room with good air circulation, away from sources of vibration, chemical fumes, and heavy foot traffic.

A controlled environment is the foundation for all successful and safe high-temperature work.

Summary Table:

| Environmental Factor | Requirement | Purpose |

|---|---|---|

| Ambient Temperature | 0°C to 40°C | Protects controller electronics from failure and overheating |

| Relative Humidity | Below 85% | Prevents condensation, shorts, and corrosion |

| Air Quality | Free of conductive dust, corrosive gases, and flammable materials | Ensures safety, prevents damage, and maintains performance |

Ensure your lab's safety and precision with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs. Contact us today to discuss how we can enhance your operations and protect your investments!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control