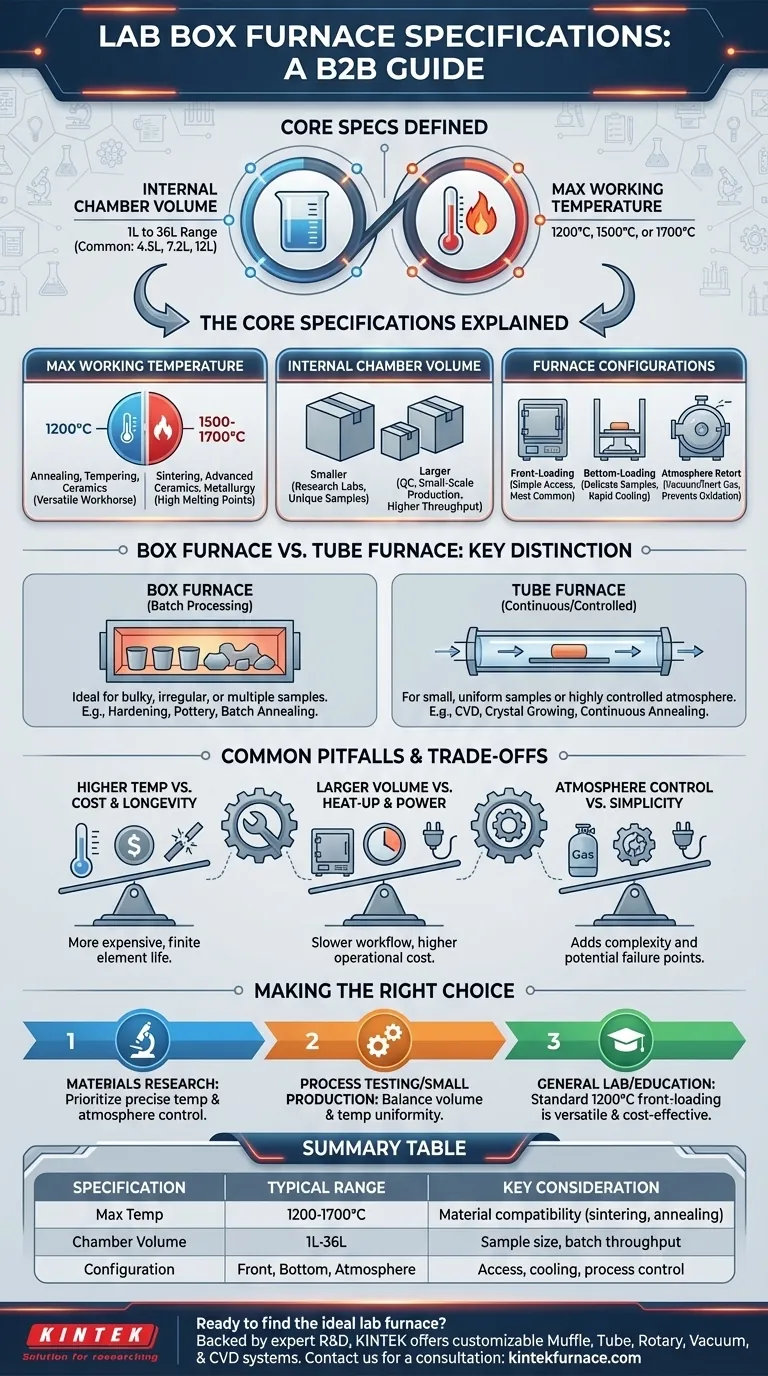

At their core, lab box furnaces are defined by their internal chamber volume and maximum achievable temperature. Typical specifications range from compact 1-liter units to larger 36-liter models, with standard working temperatures set at 1200°C, 1500°C, or 1700°C to accommodate a wide array of material processing needs.

The key to selecting the right box furnace is not just knowing the numbers, but understanding how temperature dictates the materials you can process and how volume impacts your sample size and throughput.

The Core Specifications Explained

To make an informed decision, you must understand what each primary specification enables in a laboratory or production setting. These factors directly influence the furnace's capabilities, cost, and suitability for your specific application.

Maximum Working Temperature

A furnace's temperature capability is its most critical feature. The common benchmarks are not arbitrary; they align with the processing requirements of specific material classes.

A 1200°C furnace is a versatile workhorse, suitable for many applications like annealing, tempering, and firing certain ceramics and glass.

Furnaces reaching 1500°C to 1700°C are required for high-temperature sintering, processing advanced ceramics, and metallurgical research involving materials with higher melting points.

Internal Chamber Volume

Volume determines the physical size and quantity of the samples you can process at one time.

Volumes range from 1 liter to 36 liters, with common sizes including 4.5L, 7.2L, and 12L.

Smaller volumes are ideal for research labs with unique samples, while larger chambers suit quality control or small-scale production environments that require higher throughput.

Furnace Configurations

Beyond temperature and volume, the furnace's design dictates how it interacts with the sample and its environment.

Front-loading furnaces are the most common design, offering simple access.

Bottom-loading models are often used for applications where samples are delicate or require rapid cooling by being lowered out of the heat zone.

Some furnaces are equipped with an atmosphere retort, allowing for processing in a vacuum or a controlled, inert gas environment to prevent oxidation of sensitive materials.

Box Furnace vs. Tube Furnace: A Key Distinction

While both are high-temperature tools, their geometry defines their purpose. Understanding this difference is crucial to avoid selecting the wrong instrument.

The Purpose of a Box Furnace

A box furnace excels at batch processing. Its large, open chamber is ideal for holding multiple samples, bulky or irregularly shaped objects, or components placed in crucibles.

This makes it the standard choice for applications like hardening steel parts, firing ceramic pottery, or annealing a batch of components.

The Purpose of a Tube Furnace

A tube furnace is designed for processing materials within a narrow tube. This configuration is perfect for small, uniform samples or for processes that require a highly controlled atmosphere flowing over the material.

They are the preferred tool for applications like chemical vapor deposition (CVD), growing crystals, or annealing wires in a continuous process.

Common Pitfalls and Trade-offs

Choosing a furnace involves balancing capability with practical constraints. Pushing for the highest specifications is not always the best strategy.

Higher Temperature vs. Cost and Longevity

Furnaces capable of reaching 1700°C are significantly more expensive than 1200°C models due to more advanced heating elements and insulation. These high-performance elements also have a finite lifespan and can be costly to replace.

Larger Volume vs. Heat-Up Time and Power

A larger chamber requires more energy and time to reach its target temperature. This can slow down your workflow and increase operational costs. Overspecifying the volume leads to unnecessary energy consumption for every run.

Atmosphere Control vs. Simplicity

A furnace with vacuum or inert gas capabilities offers tremendous process control for sensitive materials. However, it adds significant complexity, cost, and potential points of failure compared to a standard air-atmosphere furnace.

Making the Right Choice for Your Application

Your final decision should be guided by your primary goal. Match the furnace's specifications directly to the demands of your materials and process.

- If your primary focus is materials research: Prioritize precise temperature control and consider models with atmosphere control options to handle sensitive or reactive samples.

- If your primary focus is process testing or small-scale production: Balance chamber volume with temperature uniformity to ensure consistent results across larger batches.

- If your primary focus is general-purpose lab work or education: A standard 1200°C front-loading box furnace offers the greatest versatility and cost-effectiveness for a wide range of tasks.

Ultimately, selecting the correct furnace is about precisely matching the tool to the task at hand.

Summary Table:

| Specification | Typical Range | Key Consideration |

|---|---|---|

| Max Temperature | 1200°C, 1500°C, 1700°C | Dictates material compatibility (e.g., sintering, annealing). |

| Chamber Volume | 1L to 36L | Impacts sample size and batch throughput. |

| Configuration | Front-loading, Bottom-loading, Atmosphere | Defines sample access, cooling rate, and process control. |

Ready to find the ideal lab furnace for your specific needs?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique requirements. Our team will help you navigate the specifications to ensure you get a furnace that perfectly matches your materials and process goals.

Contact us today for a personalized consultation and quote!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?