In short, modern box furnaces are controlled by sophisticated digital systems. These controllers use feedback from temperature sensors to precisely regulate the power sent to the heating elements, ensuring the furnace chamber achieves and maintains the desired temperature with remarkable accuracy.

The transition from manual to digital control is the single most important advancement in modern furnace technology. It’s not merely about convenience; it’s about enabling repeatable, highly precise, and energy-efficient thermal processing that was previously unattainable.

The Core of Modern Furnace Control

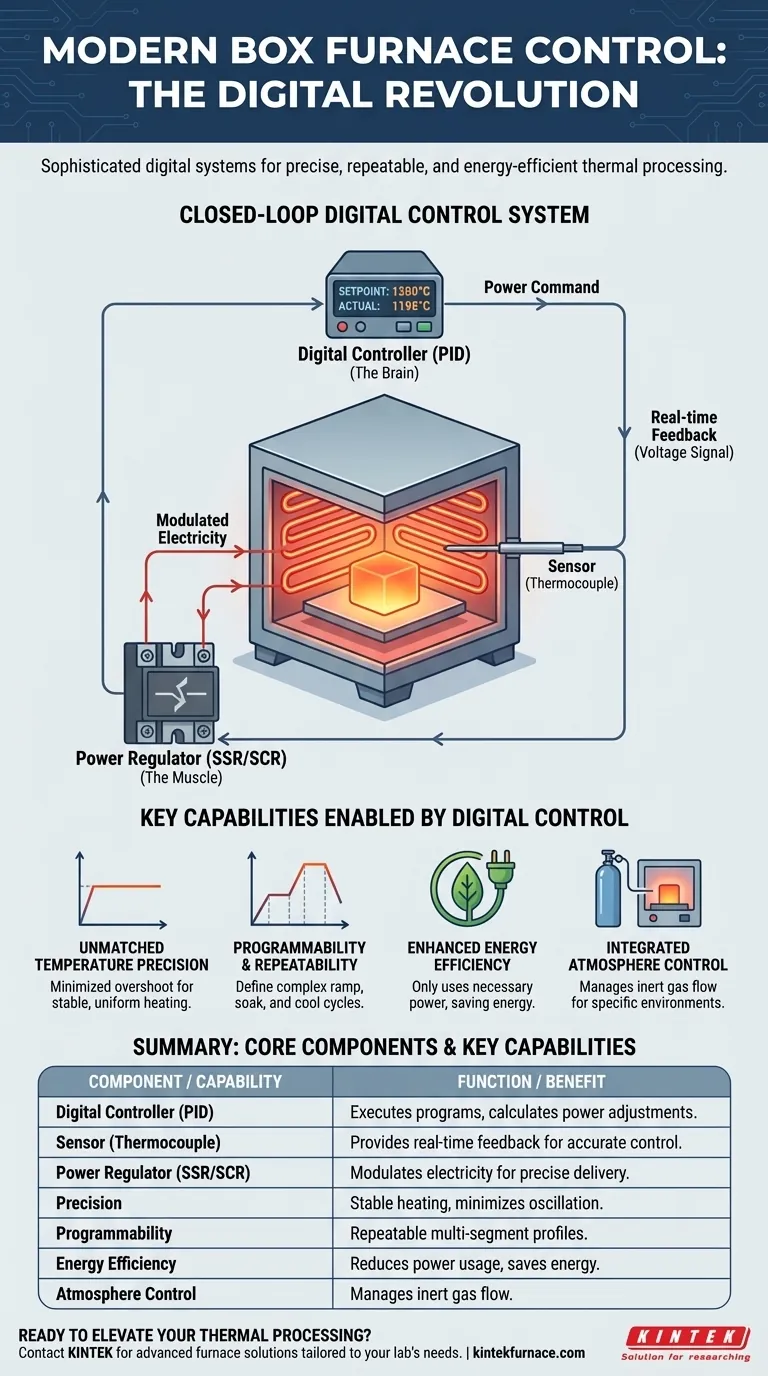

At the heart of every modern box furnace is a closed-loop digital control system. This system consists of three critical components working in concert to manage the heating process automatically.

The Digital Controller (The Brain)

The central component is a microprocessor-based controller, often a PID (Proportional-Integral-Derivative) controller. This is the brain that executes the heating program.

It continuously compares the actual furnace temperature to the desired temperature (the setpoint) and calculates the precise amount of power needed to close that gap without overshooting the target.

The Sensor (The Nerves)

To know the actual temperature, the controller relies on a sensor, typically a thermocouple. The thermocouple is placed inside the furnace chamber and generates a small voltage that corresponds directly to the chamber's temperature.

This real-time feedback is the "nerve signal" sent back to the controller, allowing it to make constant, intelligent adjustments.

The Power Regulator (The Muscle)

The controller’s commands are carried out by a power regulation device, such as a Solid-State Relay (SSR) or Silicon-Controlled Rectifier (SCR).

Instead of crudely turning the heating elements fully on or off, these devices modulate the flow of electricity. They act like a highly precise valve, delivering just enough power to the elements to gently approach and hold the setpoint temperature.

Key Capabilities Enabled by Digital Control

This automated, intelligent system provides benefits that extend far beyond just holding a single temperature.

Unmatched Temperature Precision

PID algorithms excel at minimizing temperature overshoot and oscillation. This results in extremely stable and uniform heating, which is critical for sensitive materials and processes.

Programmability and Repeatability

Most digital controllers allow users to program complex, multi-segment heating profiles. You can define specific ramping rates (how fast to heat up), soaking periods (how long to hold a temperature), and cooling steps.

Once a program is saved, it can be run identically every time, eliminating human error and ensuring process repeatability.

Enhanced Energy Efficiency

By precisely modulating power, the furnace only uses the energy it needs. During a "hold" or "soak" period, the controller might only use a small fraction of the furnace's maximum power to maintain temperature, leading to significant energy savings.

Integrated Atmosphere Control

For applications requiring an inert environment, many modern controllers can manage more than just heat. They can be integrated with gas flow systems to automatically purge the chamber with gases like argon or nitrogen at specific points in the heating cycle.

Understanding the Trade-offs

While digital control is a massive leap forward, it's important to understand the practical considerations.

Complexity vs. Functionality

A furnace with a simple, single-setpoint controller is very easy to use. A fully programmable, multi-gas controller is far more powerful but has a steeper learning curve for operators.

The Importance of Calibration

Digital systems are reliable, but the physical sensors are not immune to wear. Thermocouples can drift or degrade over time, especially at very high temperatures. Regular verification or calibration is essential to ensure the controller is acting on accurate information.

Data Logging and Connectivity

Advanced features like remote monitoring, process data logging for quality control, and network integration are increasingly common. However, these are often optional upgrades that add to the unit's cost and complexity.

Making the Right Choice for Your Goal

The ideal control system depends entirely on your specific application and requirements.

- If your primary focus is simple heat treating or drying: A basic digital controller with a reliable PID function and a clear display is perfectly sufficient.

- If your primary focus is complex material synthesis or advanced ceramics: You will need a fully programmable controller capable of storing multiple multi-segment recipes.

- If your primary focus is processing oxygen-sensitive materials: A control system with integrated atmosphere management and safety interlocks is non-negotiable.

Ultimately, understanding your furnace's control system is the key to mastering your thermal process and achieving consistent, high-quality results.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Digital Controller (PID) | Executes heating programs | Compares setpoint to actual temperature, calculates power adjustments |

| Sensor (Thermocouple) | Measures furnace temperature | Provides real-time feedback for accurate control |

| Power Regulator (SSR/SCR) | Modulates electricity to heating elements | Enables precise power delivery, reduces overshoot |

| Key Capabilities | Benefits | Examples |

| Temperature Precision | Stable, uniform heating | Minimizes oscillation for sensitive materials |

| Programmability | Repeatable multi-segment profiles | Ramping rates, soaking periods, cooling steps |

| Energy Efficiency | Reduces power usage | Saves energy during hold periods |

| Atmosphere Control | Manages inert gas flow | Integrates with gas systems for specific cycles |

Ready to elevate your thermal processing with advanced furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization capabilities to meet unique experimental requirements. Contact us today to discuss how our precision-controlled furnaces can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.