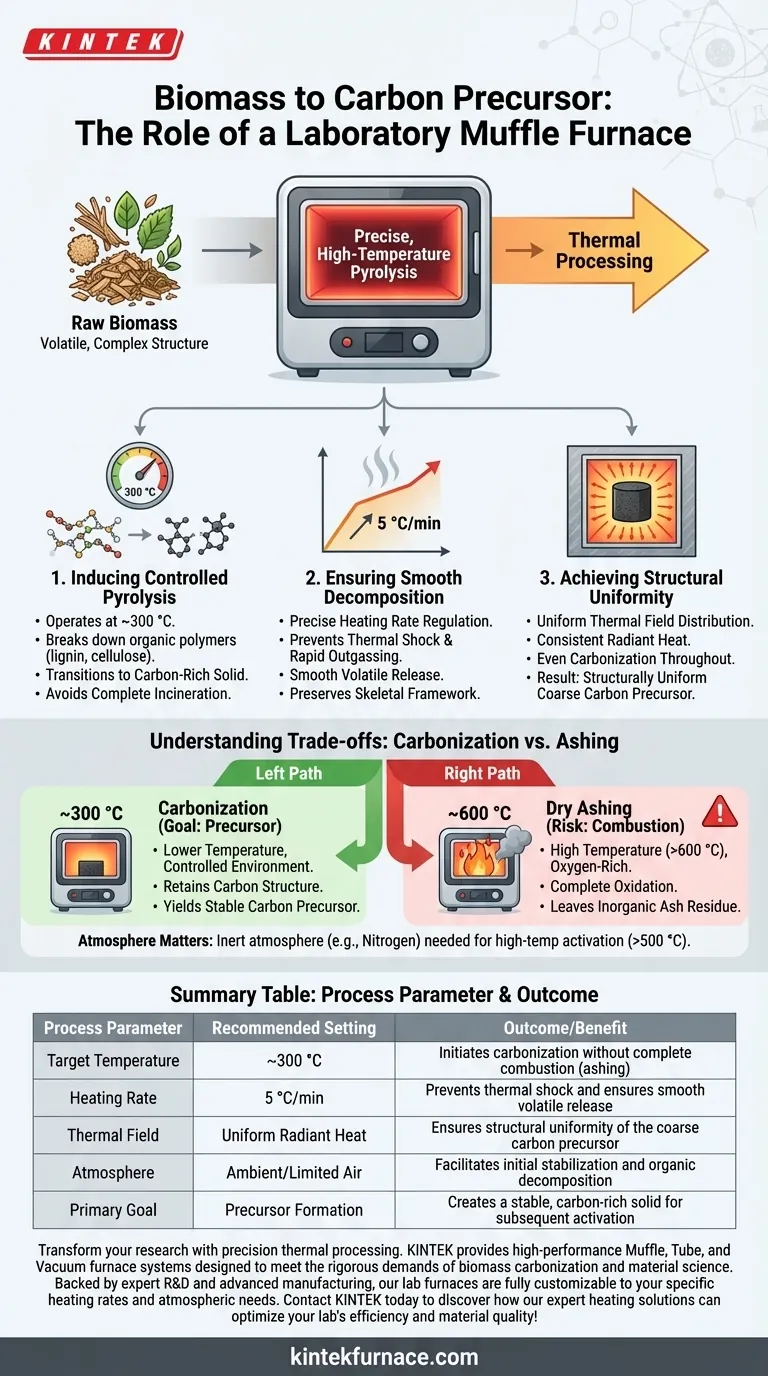

A laboratory muffle furnace acts as the foundational thermal processing unit for converting raw biomass into stable carbon precursors. It provides a precise, high-temperature pyrolysis environment—typically around 300 °C—that induces the initial carbonization reaction. By maintaining a steady heating rate and a uniform thermal field, the furnace ensures the organic components decompose smoothly rather than burning unevenly.

Core Takeaway The muffle furnace is not just a heater; it is a stabilization tool. Its ability to provide a consistent heating rate (e.g., 5 °C/min) and uniform heat distribution allows for the controlled removal of volatiles, resulting in a structurally uniform "coarse" carbon precursor essential for subsequent activation steps.

The Mechanism of Transformation

The conversion of biomass to a carbon precursor is a delicate balance between thermal decomposition and structural preservation. The muffle furnace achieves this through specific control mechanisms.

Inducing Controlled Pyrolysis

To create a carbon precursor, the biomass must undergo pyrolysis—thermal decomposition in a controlled environment. The muffle furnace typically operates at 300 °C for this specific application.

At this temperature, the furnace facilitates the breakdown of complex organic polymers (like lignin and cellulose) without incinerating the material completely. This step is critical for transitioning the material from raw biological matter to a carbon-rich solid.

Ensuring Smooth Decomposition

The rate at which temperature increases is as critical as the final temperature. The muffle furnace offers precise regulation of heating rates, commonly set to 5 °C/min.

This gradual ramp-up prevents thermal shock and rapid outgassing, which could crack or shatter the material's structure. By controlling the rate, the furnace ensures the release of volatile components is "smooth," preserving the skeletal framework of the biomass.

Achieving Structural Uniformity

A key advantage of the muffle furnace is its uniform thermal field distribution.

Unlike direct heating methods that may create hot spots, the muffle furnace surrounds the sample with consistent radiant heat. This ensures that the biomass carbonizes evenly throughout its volume, resulting in a structurally uniform coarse carbon precursor rather than a mix of unburnt biomass and ash.

Understanding the Trade-offs

While the muffle furnace is ideal for creating the initial carbon precursor, it is essential to understand the boundaries of its operation to avoid process failure.

The Risk of Over-Oxidation (Ashing)

One must be careful not to confuse carbonization with dry ashing. If the muffle furnace temperature is raised too high (e.g., 600 °C) in an oxygen-rich environment, the process shifts from carbonization to complete combustion.

As noted in comparative processes, high temperatures in air will fully oxidize the organic matter, leaving behind only inorganic mineral residue (ash). To obtain a carbon precursor, the temperature must be kept in the lower range (around 300 °C) to retain the carbon structure.

Atmosphere Limitations

Standard muffle furnaces are excellent for the initial stabilization and coarse carbonization steps. However, for high-temperature activation (e.g., >500 °C) where preventing oxidation is paramount, a system with a strictly controlled inert atmosphere (like a horizontal tube furnace using nitrogen) is often required to prevent the precursor from burning away.

Making the Right Choice for Your Goal

How you utilize the muffle furnace depends entirely on the desired end-state of your biomass material.

- If your primary focus is creating a Carbon Precursor: Operate the furnace at approximately 300 °C with a slow ramp (5 °C/min) to maximize carbon yield and structural uniformity.

- If your primary focus is Mineral Analysis: Raise the temperature to 600 °C to induce complete oxidation (ashing), removing all carbon to isolate the inorganic content.

- If your primary focus is High-Temp Activation: Use the muffle furnace only for the initial stabilization (precursor step), then transfer the material to a controlled-atmosphere unit for high-temperature treatment.

By leveraging the muffle furnace for its thermal stability and precision, you turn volatile biomass into a reliable, uniform foundation for advanced carbon materials.

Summary Table:

| Process Parameter | Recommended Setting | Outcome/Benefit |

|---|---|---|

| Target Temperature | ~300 °C | Initiates carbonization without complete combustion (ashing) |

| Heating Rate | 5 °C/min | Prevents thermal shock and ensures smooth volatile release |

| Thermal Field | Uniform Radiant Heat | Ensures structural uniformity of the coarse carbon precursor |

| Atmosphere | Ambient/Limited Air | Facilitates initial stabilization and organic decomposition |

| Primary Goal | Precursor Formation | Creates a stable, carbon-rich solid for subsequent activation |

Transform your research with precision thermal processing. KINTEK provides high-performance Muffle, Tube, and Vacuum furnace systems designed to meet the rigorous demands of biomass carbonization and material science. Backed by expert R&D and advanced manufacturing, our lab furnaces are fully customizable to your specific heating rates and atmospheric needs. Contact KINTEK today to discover how our expert heating solutions can optimize your lab's efficiency and material quality!

Visual Guide

References

- Rajib Samanta, Sudip Barman. Correlating the Sodium Storage Mechanism and Enhancing the Initial Coulombic Efficiency of Biomass‐Derived Hard Carbon in Sodium‐Ion Batteries. DOI: 10.1002/batt.202500295

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key specifications of a typical muffle furnace? Essential Guide for Lab Efficiency

- What are the benefits of front loading furnaces? Boost Efficiency and Safety in Your Lab

- What are the typical temperature ranges for muffle furnaces and their applications? Optimize Your Lab's Thermal Processes

- How do muffle furnaces contribute to drug testing in pharmaceuticals? Ensure Purity and Compliance with Precision

- What should homeowners consider when switching to an electric furnace? Avoid Costly Mistakes with This Guide

- How does a muffle furnace function in Co3O4 nanocatalyst calcination? Optimize Your Catalyst Performance

- What are the established design features of a Box Furnace? A Guide to Versatile, Heavy-Duty Heating

- How is an industrial-grade ashing furnace utilized in 3D-printed bioactive glass? Master Debinding & Sintering