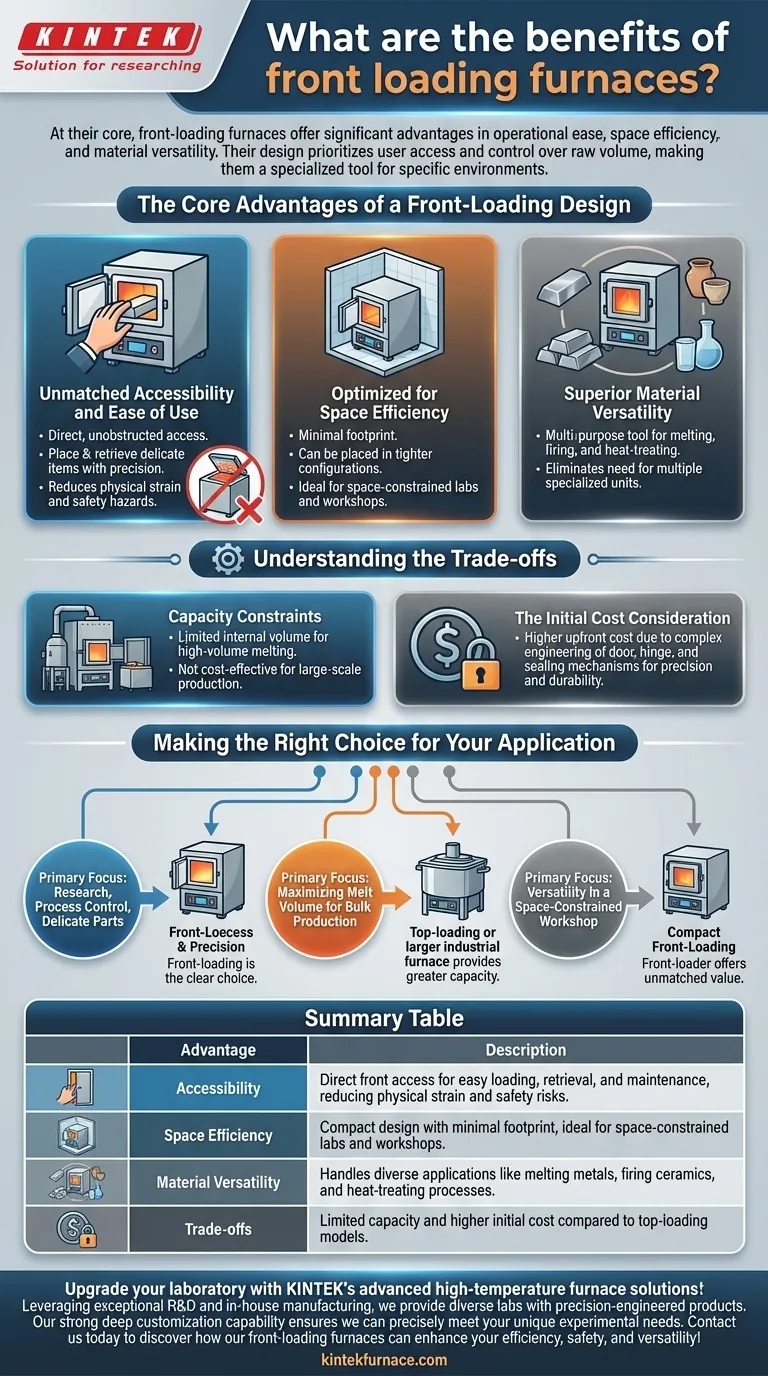

At their core, front-loading furnaces offer significant advantages in operational ease, space efficiency, and material versatility. Their design prioritizes user access and control over raw volume, making them a specialized tool for specific environments. The ability to directly access the chamber from the front simplifies loading and maintenance, while their compact structure is ideal for labs and workshops where space is a premium.

The decision to use a front-loading furnace is a strategic choice for precision and convenience over sheer capacity. While other designs may offer greater volume, the front-loader excels in controlled settings where ease of access, safety, and a smaller footprint are the primary drivers.

The Core Advantages of a Front-Loading Design

The benefits of a front-loading furnace stem directly from its door-centric architecture, which impacts everything from daily operation to facility layout.

Unmatched Accessibility and Ease of Use

The most defining benefit is the direct, unobstructed access to the heating chamber. This is not merely a convenience; it is a fundamental operational and safety advantage.

Operators can place and retrieve materials, especially delicate items like ceramics or lab samples, with greater precision and less risk of damage. This ergonomic design reduces physical strain and minimizes the safety hazards associated with reaching over a hot opening, which is common with top-loading models.

Optimized for Space Efficiency

Front-loading furnaces are engineered to have a minimal footprint. Because access is only required from the front, they can be placed in tighter configurations within a lab or workshop.

This is a critical factor in research and development facilities or small-scale production environments where floor space is expensive and must be maximized for multiple processes.

Superior Material Versatility

These furnaces are often designed as multi-purpose tools capable of handling a wide range of applications.

From melting metals and glass to firing ceramics and conducting heat-treating processes, a single front-loading furnace can serve the needs of a diverse workshop, eliminating the need for multiple specialized units.

Understanding the Trade-offs

To make an informed decision, you must weigh the clear benefits against the inherent design limitations. No single furnace design is universally superior; the choice always involves trade-offs.

Capacity Constraints

The primary trade-off for a front-loading design is its limited capacity. The engineering required for a robust, well-sealed front door inherently restricts the internal volume compared to simpler top-loading or crucible furnace designs.

For high-volume melting or large-scale industrial production, a front-loading furnace is rarely the most efficient or cost-effective option.

The Initial Cost Consideration

Front-loading furnaces tend to have a higher upfront cost compared to top-loading models of similar internal capacity.

This price difference is due to the more complex engineering involved in the door, hinge, and sealing mechanisms, which must provide a perfect seal to maintain thermal efficiency and safety over thousands of cycles. You are paying a premium for precision, durability, and convenience.

Making the Right Choice for Your Application

Selecting the right furnace requires a clear understanding of your primary operational goal. The "best" furnace is the one that best aligns with your specific needs.

- If your primary focus is on research, process control, or handling delicate parts: The superior access, safety, and precision of a front-loading furnace make it the clear choice.

- If your primary focus is maximizing melt volume for bulk production: A top-loading or larger industrial furnace will provide greater capacity and likely a lower cost-per-kilogram.

- If your primary focus is versatility in a space-constrained workshop: The front-loader's ability to handle diverse materials within a compact design offers unmatched value.

Ultimately, choosing the right furnace is about aligning its design philosophy with your specific operational priorities.

Summary Table:

| Advantage | Description |

|---|---|

| Accessibility | Direct front access for easy loading, retrieval, and maintenance, reducing physical strain and safety risks. |

| Space Efficiency | Compact design with minimal footprint, ideal for space-constrained labs and workshops. |

| Material Versatility | Handles diverse applications like melting metals, firing ceramics, and heat-treating processes. |

| Trade-offs | Limited capacity and higher initial cost compared to top-loading models. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision-engineered products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs. Contact us today to discover how our front-loading furnaces can enhance your efficiency, safety, and versatility!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure