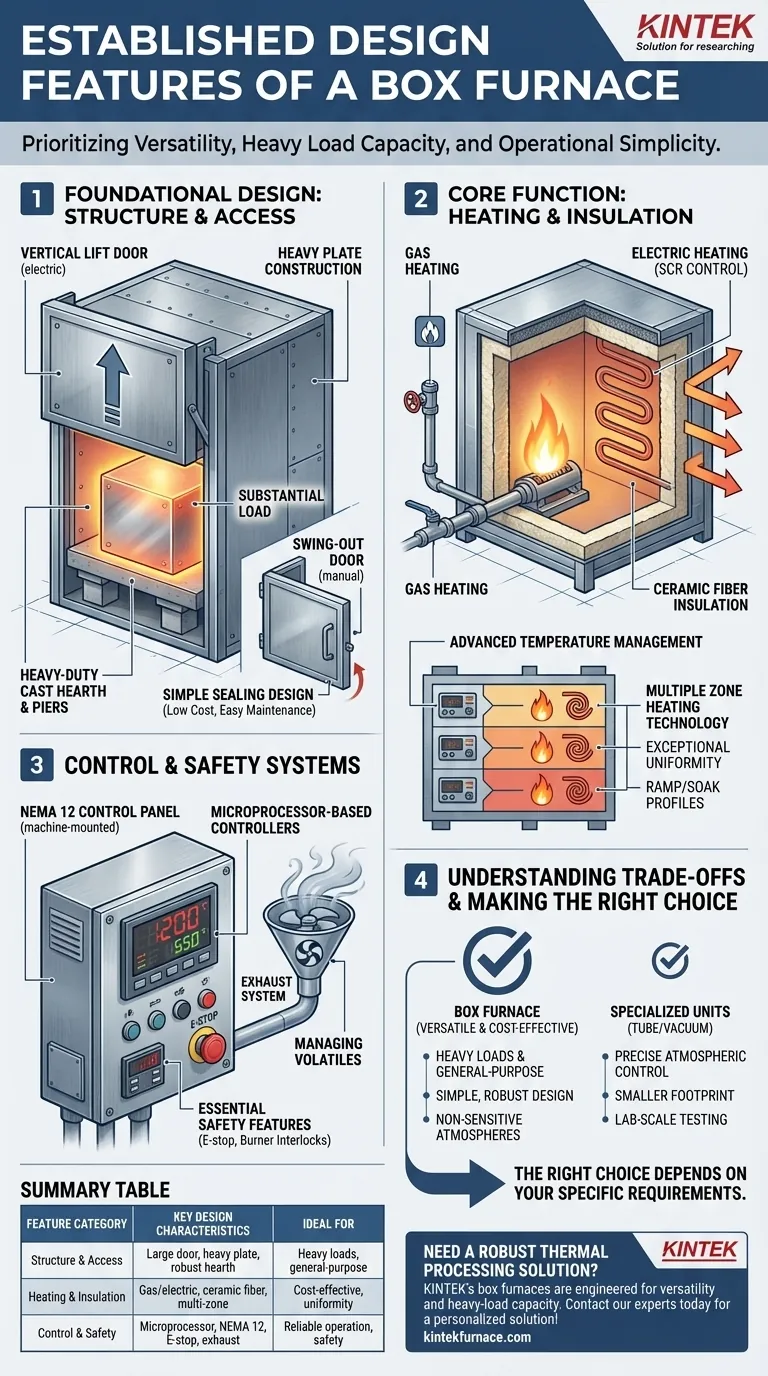

At its core, a Box Furnace is defined by a set of established design features that prioritize versatility, heavy load capacity, and operational simplicity. Key characteristics include a large access door (either vertical lift or swing-out), energy-efficient insulation, options for gas or electric heating, a robust hearth structure for supporting heavy parts, and modern, microprocessor-based control systems for managing temperature.

A Box Furnace is engineered for general-purpose thermal processing. Its design balances robust construction and operational flexibility, making it a cost-effective workhorse for applications that do not require strictly controlled atmospheres.

Foundational Design: Structure and Access

The physical construction of a box furnace is central to its function, emphasizing durability and ease of use for a wide range of parts and processes.

The Loading Door: Vertical Lift vs. Swing-Out

Most box furnaces feature either an electric vertical lift door or a manual swing-out door. This design choice facilitates easy loading and unloading of products, accommodating various sizes and weights with minimal effort.

Heavy-Duty Construction

These furnaces are built with heavy plate construction to withstand industrial environments and support substantial loads. This is complemented by a heavy-duty cast hearth and piers, which provide a stable, durable surface for the workpiece.

Simple Sealing Design

The furnace doors typically employ a common, straightforward sealing mechanism. This contributes to a lower overall cost and simplifies maintenance, making the furnace a practical choice for many applications.

The Core Function: Heating and Insulation

The heating system is the heart of the furnace, designed for efficiency, control, and uniformity.

Heating Systems: Gas and Electric Options

Box furnaces are available with either fully proportional gas or electric heat. Electric versions are often managed by SCR (Silicon Controlled Rectifier) power controls, while gas models incorporate robust burner safety equipment.

Energy-Efficient Insulation

To maximize thermal efficiency and minimize energy loss, these furnaces utilize high-quality ceramic fiber insulation. This material provides excellent heat retention while keeping the external structure cool.

Advanced Temperature Management

Many designs integrate multiple zone heating technology. This allows for exceptional temperature uniformity across the chamber and precise management of complex ramp/soak heating and cooling profiles required by certain processes.

Control and Safety Systems

Modern control and safety features are integral to the reliable and safe operation of any box furnace.

State-of-the-Art Control Packages

A standard feature is a NEMA 12 control panel, which is typically machine-mounted. This houses microprocessor-based temperature controllers for the furnace chamber and a separate high-limit controller to prevent overheating.

Essential Safety Features

Safety is paramount, with features like a single-button E-stop on the control panel for immediate shutdowns. Gas-fired units are equipped with all necessary burner safety interlocks.

Managing Volatiles: Exhaust Systems

For processes that burn off volatile materials, box furnaces can be equipped with exhaust systems. These may include fume hoods or more localized snorkel hoods to safely vent gases and protect the operator and workspace.

Understanding the Trade-offs

No single design is perfect for every task. Understanding the inherent trade-offs of the box furnace design is key to making an informed decision.

Versatility vs. Specialization

The box furnace is a versatile generalist. Its simple, robust design is a key strength but contrasts with specialized units like a vertical tube furnace. A tube furnace offers a smaller footprint and uses gravity to ensure even heating for specific material testing or chemical reactions, but it cannot handle the size and weight of parts a box furnace can.

Cost vs. Atmospheric Control

The box furnace's simple sealing design makes it highly cost-effective. However, this same feature makes it unsuitable for applications requiring strict environmental conditions, such as a high vacuum or a pure inert gas atmosphere, where a more specialized furnace would be necessary.

Making the Right Choice for Your Application

Selecting the correct furnace depends entirely on the specific requirements of your thermal process.

- If your primary focus is heavy loads and general-purpose heat treating: The box furnace's heavy plate construction, robust hearth, and large access doors make it the ideal choice.

- If your primary focus is cost-effectiveness for non-sensitive atmospheres: The simple, reliable sealing design and overall structure of a box furnace offer an excellent balance of performance and value.

- If your primary focus is precise atmospheric control or lab-scale testing: A specialized unit, such as a tube furnace or a vacuum furnace, will provide the controlled environment that a standard box furnace cannot.

By understanding these core design principles, you can confidently determine if a box furnace is the right tool for your specific thermal processing needs.

Summary Table:

| Feature Category | Key Design Characteristics |

|---|---|

| Structure & Access | Large vertical lift/swing-out door, heavy plate construction, robust cast hearth |

| Heating & Insulation | Gas or electric heating, ceramic fiber insulation, multi-zone heating for uniformity |

| Control & Safety | Microprocessor-based controllers, NEMA 12 panel, E-stop, exhaust systems for volatiles |

| Ideal For | Heavy loads, general-purpose heat treating, cost-effective operation in non-sensitive atmospheres |

Need a robust thermal processing solution?

KINTEK's box furnaces are engineered for versatility and heavy-load capacity, perfectly aligning with the design features outlined above. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Muffle, Tube, and Box Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Let's discuss how a KINTEK box furnace can enhance your lab's efficiency and reliability. Contact our experts today for a personalized solution!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts