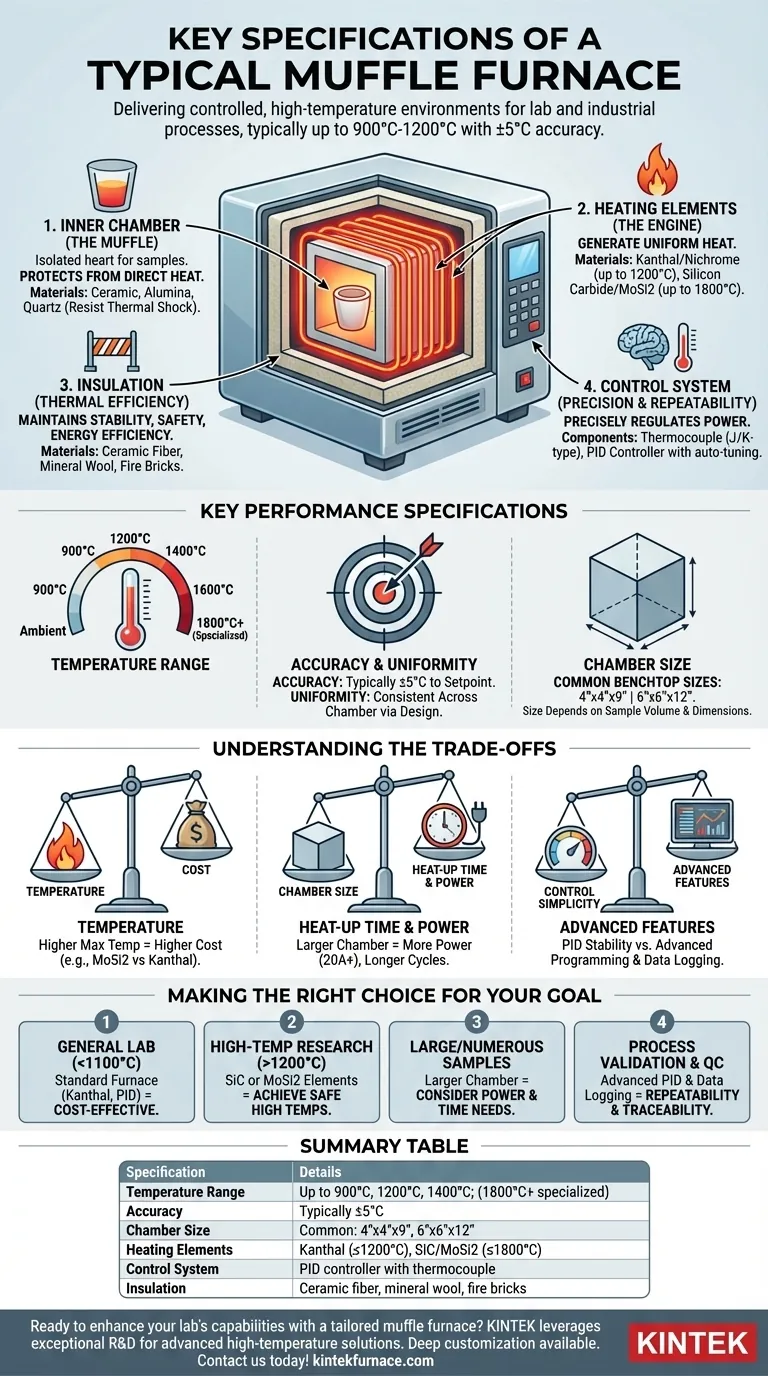

At its core, a typical muffle furnace is defined by its operational temperature range, internal chamber size, method of temperature control, and the materials used in its construction. These specifications work in concert to deliver controlled, high-temperature environments for laboratory and industrial processes, with most standard models operating up to 900°C or 1200°C with an accuracy of ±5°C.

Understanding a muffle furnace isn't just about memorizing specifications. It's about seeing how its core components—the chamber, heating elements, and controller—work together to achieve a specific temperature profile with the required precision and safety for your task.

Deconstructing the Muffle Furnace: Core Components

To truly grasp the specifications, you must first understand the function of each major part. The furnace is a system where each component's quality dictates the overall performance.

The Inner Chamber (The Muffle)

The inner chamber, or muffle, is the isolated heart of the furnace where samples are placed. It is responsible for protecting the sample from direct contact with the heating elements.

This chamber is constructed from high-grade, refractory materials like ceramic, alumina, or quartz, chosen for their ability to withstand extreme thermal shock without degrading.

Heating Elements: The Engine of the Furnace

Heating elements are the components that generate heat. They are typically arranged around the outside of the muffle to ensure uniform temperature distribution.

The material used for the element is the primary factor determining the furnace's maximum temperature. Common materials include Kanthal (A1) or nickel-chromium (nichrome) for temperatures up to 1200°C, and Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2) for higher-temperature applications up to 1800°C.

Insulation: Maximizing Thermal Efficiency

Effective insulation is critical for maintaining temperature stability, ensuring operator safety, and improving energy efficiency. It prevents heat from escaping the chamber.

Materials like ceramic fiber, mineral wool, or high-grade fire bricks are packed between the inner chamber and the outer casing, providing a thermal barrier.

The Control System: Precision and Repeatability

The control system is the brain of the furnace. It consists of a temperature sensor, a controller, and a display.

A thermocouple (J-type or K-type) measures the chamber's temperature and sends this data to the controller.

Modern furnaces use a PID (Proportional-Integral-Derivative) controller, often with auto-tuning features, to precisely regulate power to the heating elements. This system minimizes temperature overshoots and maintains the setpoint with high accuracy.

Key Performance Specifications Explained

These component choices result in a set of measurable performance metrics that define what the furnace can do.

Temperature Range

This is the most critical specification. A standard furnace typically operates from ambient temperature up to 900°C, 1200°C, or 1400°C.

Specialized models designed for advanced materials processing can reach 1800°C or higher, but these require more exotic and expensive heating elements and insulation.

Accuracy and Uniformity

Accuracy refers to how closely the actual chamber temperature matches the setpoint on the controller. For most muffle furnaces, this is specified as ±5°C.

Uniformity describes the temperature consistency across different points within the chamber. While often not given a numeric value, it is a key feature achieved through careful design of the heating elements' placement.

Chamber Size

The internal, usable volume of the furnace is specified by its dimensions (Height x Width x Depth).

Common benchtop sizes include 4" x 4" x 9" and 6" x 6" x 12". The required size depends entirely on the volume and dimensions of the samples you intend to process.

Understanding the Trade-offs

Selecting a furnace involves balancing performance, longevity, and cost. Understanding the inherent trade-offs is essential for making an informed decision.

Temperature vs. Cost: The Heating Element Dilemma

The single biggest factor driving cost is the maximum operating temperature. A furnace rated for 1200°C using Kanthal elements is significantly less expensive than one rated for 1700°C that requires MoSi2 elements.

Do not over-specify your temperature needs. Purchasing a furnace with a much higher temperature range than you require leads to unnecessary capital expense.

Chamber Size vs. Heat-Up Time and Power

A larger chamber provides more capacity but comes with clear downsides. It requires more power to heat (20A or more is common) and will have a longer heat-up and cool-down cycle.

If you process small samples, choosing a smaller chamber will save time, energy, and often lab space.

Control Simplicity vs. Advanced Features

While most modern furnaces use reliable digital PID controllers, some applications may demand more advanced features like programmable multi-step cycles or data logging. These features add complexity and cost.

Conversely, a simple digital indicator may suffice for non-critical processes but lacks the stability and repeatability of a PID system for sensitive work.

Making the Right Choice for Your Goal

Your application dictates the required specifications. Use the following guidelines to select the right tool for the job.

- If your primary focus is general laboratory ashing or heat treating below 1100°C: A standard furnace with Kanthal heating elements and a reliable PID controller is the most cost-effective and appropriate choice.

- If your primary focus is high-temperature materials research (above 1200°C): You must invest in a furnace equipped with Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2) elements to achieve and sustain these temperatures safely.

- If your primary focus is processing large or numerous samples simultaneously: Prioritize a larger chamber volume, but ensure your facility can meet the higher power requirements and accommodate longer cycle times.

- If your primary focus is process validation and quality control: Emphasize a furnace with an advanced PID controller, over-temperature protection, and potentially data logging capabilities to ensure repeatability and traceability.

By understanding how these specifications relate to the furnace's core function, you can confidently select the precise instrument your work demands.

Summary Table:

| Specification | Details |

|---|---|

| Temperature Range | Up to 900°C, 1200°C, or 1400°C; specialized models up to 1800°C |

| Accuracy | Typically ±5°C |

| Chamber Size | Common sizes: 4" x 4" x 9", 6" x 6" x 12" |

| Heating Elements | Kanthal (up to 1200°C), SiC or MoSi2 (up to 1800°C) |

| Control System | PID controller with thermocouple sensors |

| Insulation | Ceramic fiber, mineral wool, or fire bricks |

Ready to enhance your lab's capabilities with a tailored muffle furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs—contact us today to discuss how we can optimize your processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control