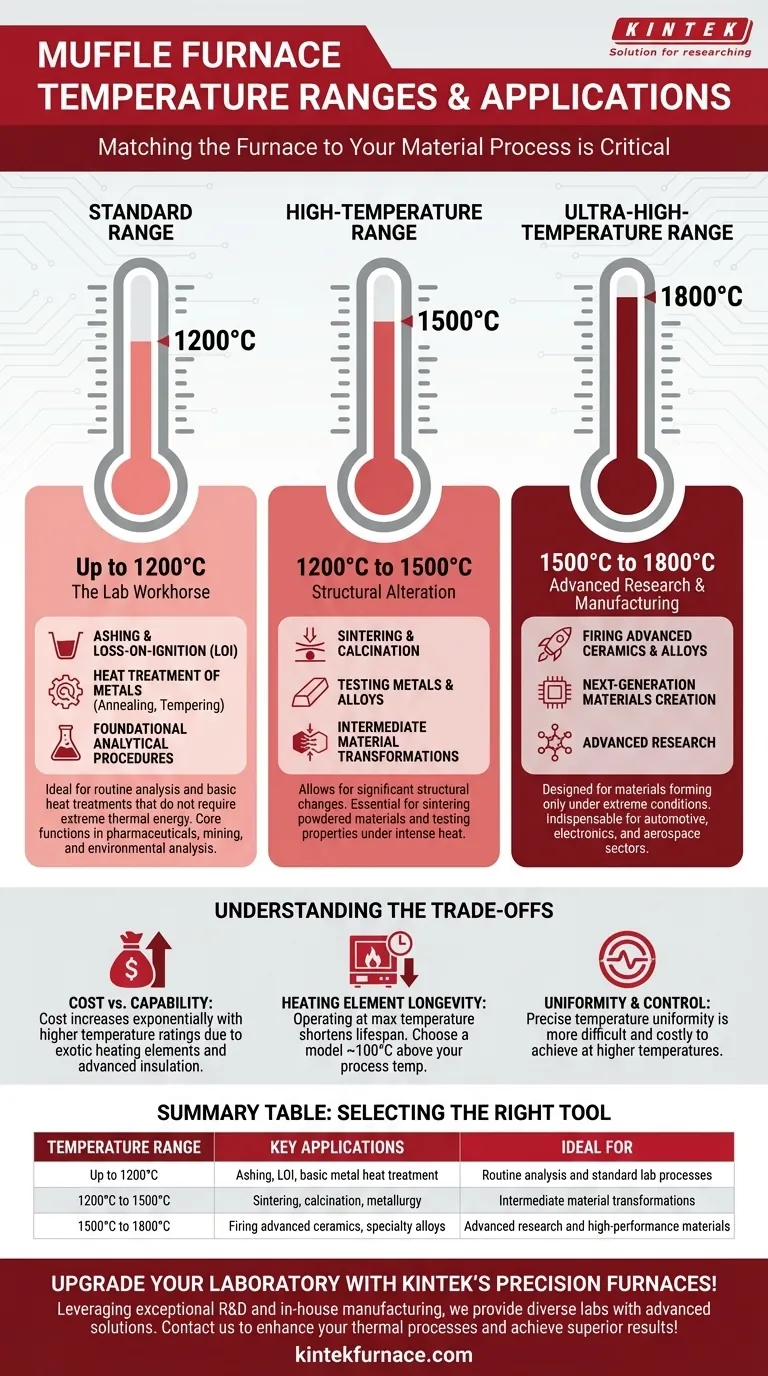

In material science and analysis, muffle furnaces are categorized by their maximum operating temperature, which directly dictates their application. Standard models typically operate from 300°C to 1200°C, high-temperature models reach 1500°C, and ultra-high-temperature units can achieve 1800°C. Each tier is engineered for specific thermal processes, from basic sample preparation to the development of advanced materials.

The critical insight is not the furnace's maximum temperature, but matching the furnace's operational range to the specific material transformation you need to achieve. Choosing the right furnace is about understanding whether your goal is simple combustion, structural alteration, or high-energy material fusion.

Understanding the Three Tiers of Muffle Furnaces

Muffle furnaces are not one-size-fits-all. They are specialized tools where higher temperature capabilities correspond to more advanced, energy-intensive applications and significantly higher costs.

Standard Range: Up to 1200°C

This is the most common and versatile category of muffle furnace, often considered the workhorse of the general laboratory.

These furnaces are ideal for foundational analytical procedures and basic heat treatments that do not require extreme thermal energy.

High-Temperature Range: 1200°C to 1500°C

Entering the high-temperature range allows for more significant changes to a material's structure.

This tier is essential for processes like sintering, where powdered materials are fused together, and for testing the properties of many metals and alloys under intense heat.

Ultra-High-Temperature Range: 1500°C to 1800°C

This is the domain of advanced research and specialized manufacturing. These furnaces are designed for materials that only form or transform under extreme thermal conditions.

Applications are typically focused on creating or testing next-generation materials, such as high-performance ceramics and specialty alloys for aerospace or electronics.

Key Applications and Their Required Temperatures

The specific process you need to perform is the single most important factor in determining the right furnace. Each application has a well-defined temperature window for success.

Ashing and Loss-on-Ignition (LOI)

Ashing is a process that burns away all organic substances in a sample to leave only the inorganic, non-combustible residue (ash).

This is a core function in industries like pharmaceuticals, mining, and environmental analysis. It almost always occurs at temperatures between 500°C and 1000°C, placing it firmly in the standard furnace range.

Heat Treatment of Metals (Annealing, Tempering)

Heat treatment alters the physical and sometimes chemical properties of a material. Processes like annealing relieve internal stresses and soften metals, while tempering increases toughness.

These treatments are critical in metallurgy but typically occur well below the melting point of the metals, usually within the standard 1200°C range.

Sintering and Calcination

Sintering is the process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. Calcination drives off volatile substances or induces a phase transition.

These processes often require temperatures that cross the boundary from standard to high-temperature, making a high-temperature furnace (1200°C+) the appropriate choice.

Firing Advanced Ceramics and Alloys

Creating robust, heat-resistant ceramics or testing the limits of specialty alloys demands extreme thermal energy.

This is the primary driver for ultra-high-temperature furnaces (1500°C+). These tools are indispensable for research and manufacturing in the automotive, electronics, and aerospace sectors.

Understanding the Trade-offs

Selecting a furnace involves balancing capability with practical constraints. Simply choosing the model with the highest temperature is often an inefficient and costly mistake.

Cost vs. Capability

The cost of a muffle furnace increases exponentially with its maximum temperature. This is due to the need for more exotic heating elements (e.g., silicon carbide or molybdenum disilicide), thicker and more advanced insulation, and more sophisticated temperature controllers.

Heating Element Longevity

Consistently operating a furnace at its absolute maximum rated temperature will drastically shorten the lifespan of its heating elements. A best practice is to choose a model with a maximum temperature at least 100°C higher than your most common process temperature to ensure longevity and reliable performance.

Uniformity and Control

Achieving precise and uniform temperature throughout the entire chamber becomes more difficult and expensive at higher temperatures. If your process is highly sensitive to temperature variation, this becomes a critical factor in your selection.

Making the Right Choice for Your Goal

To select the correct equipment, align your primary application with the appropriate temperature tier.

- If your primary focus is routine analysis like ashing or basic metal heat treatment: A standard furnace (up to 1200°C) offers the best balance of cost and performance.

- If your primary focus is metallurgy, sintering powders, or basic ceramics: A high-temperature model (up to 1500°C) is necessary to achieve the required material transformations.

- If your primary focus is advanced materials research or firing specialty ceramics: An ultra-high-temperature furnace (1500°C+) is a non-negotiable investment in process capability.

By aligning the furnace's temperature range with your specific material process, you ensure accurate results and a wise investment in your equipment.

Summary Table:

| Temperature Range | Key Applications | Ideal For |

|---|---|---|

| Up to 1200°C | Ashing, LOI, basic metal heat treatment | Routine analysis and standard lab processes |

| 1200°C to 1500°C | Sintering, calcination, metallurgy | Intermediate material transformations |

| 1500°C to 1800°C | Firing advanced ceramics, specialty alloys | Advanced research and high-performance materials |

Upgrade your laboratory with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met precisely. Contact us today to enhance your thermal processes and achieve superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization