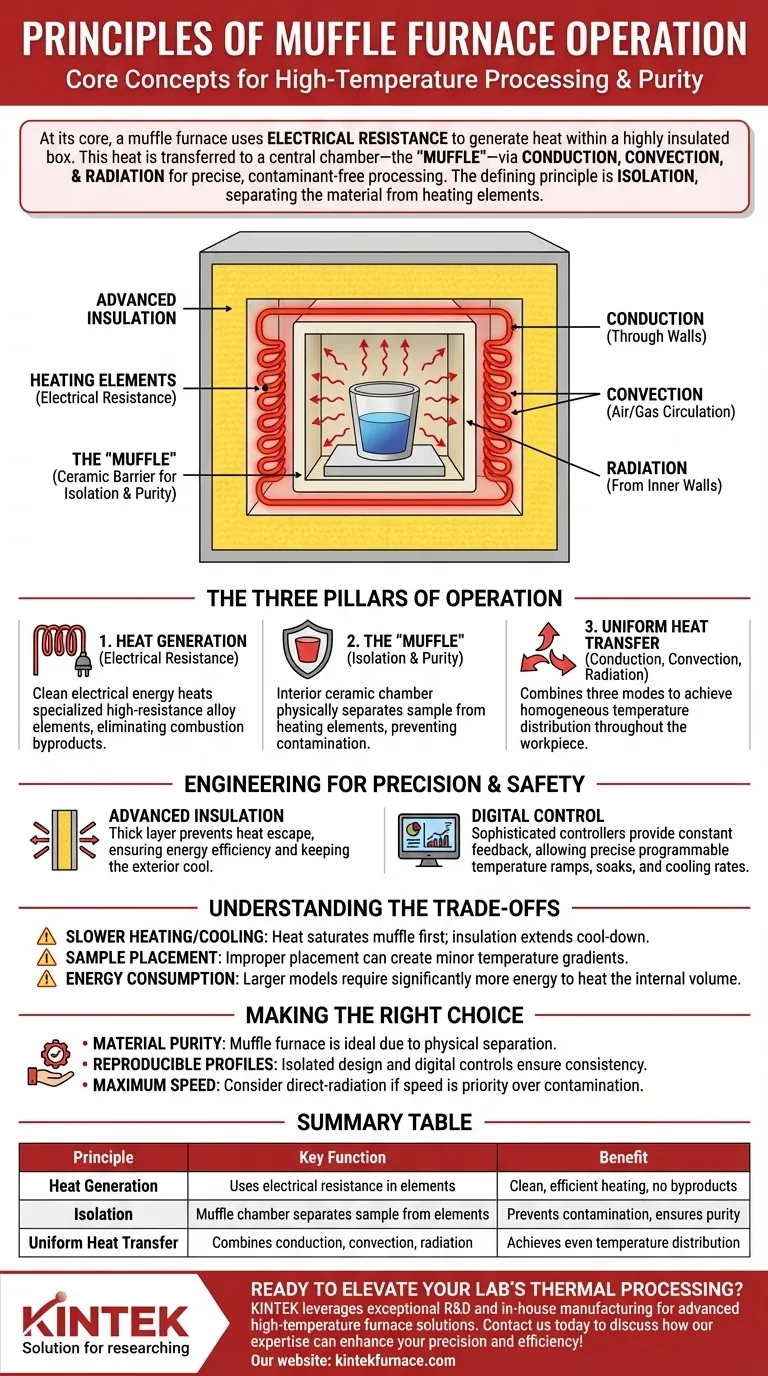

At its core, a muffle furnace operates by using electrical resistance to generate heat within a highly insulated box. This heat is then transferred to a central chamber—the "muffle"—through a combination of conduction, convection, and radiation, allowing for precise, high-temperature processing in a controlled and contaminant-free environment.

The defining principle of a muffle furnace is not just heat generation, but isolation. The "muffle" is a physical barrier that separates the material being heated from the heating elements, ensuring temperature uniformity and preventing contamination.

The Three Pillars of Muffle Furnace Operation

To truly understand how a muffle furnace achieves its results, we must look at the three distinct principles that work in concert: heat generation, isolation, and uniform transfer.

Principle 1: Heat Generation via Electrical Resistance

The process begins with clean, electrical energy. Specialized heating elements, often made from iron-chrome or similar high-resistance alloys, are positioned around the central chamber.

When a controlled electric current is passed through these elements, their natural resistance causes them to heat up intensely. This method is highly efficient and eliminates the combustion byproducts, fumes, or open flames associated with fuel-fired furnaces.

Principle 2: The "Muffle" for Isolation and Purity

The "muffle" is the heart of the furnace and its key differentiator. It is an interior chamber, typically made of high-temperature ceramic, that contains the workpiece or sample.

This chamber acts as a crucial barrier. It shields the sample from direct contact with the heating elements, preventing any potential material flaking from the elements from contaminating the sample. This isolation is what makes muffle furnaces essential for applications requiring high purity.

Principle 3: Uniform Heat Transfer

Once heat is generated, it must be delivered to the sample evenly. Muffle furnaces use three modes of heat transfer to achieve this.

- Conduction: Heat travels directly through the solid material of the muffle chamber walls to the sample's container.

- Convection: Air (or a controlled gas atmosphere) inside the chamber heats up, circulates, and transfers thermal energy to all surfaces of the sample.

- Radiation: The hot inner walls of the muffle radiate thermal energy inward, bathing the sample in heat from all directions. This "blackbody radiation" is critical for achieving a homogeneous temperature throughout the workpiece.

Engineering for Precision and Safety

The core principles are supported by key engineering features that ensure reliable and safe operation.

The Role of Advanced Insulation

Surrounding the heating elements and muffle is a thick layer of high-performance insulation. This material is designed to prevent heat from escaping into the lab environment.

This exceptional thermal containment ensures energy efficiency and keeps the exterior of the furnace cool to the touch, which is a critical safety feature for operators.

The Importance of Digital Control

Modern muffle furnaces are not simply "on/off" devices. They are integrated with sophisticated digital controllers and thermocouples that provide a constant feedback loop.

These controllers allow the user to program precise temperature ramps, hold times (soaks), and controlled cooling rates. This transforms the furnace from a simple oven into a reproducible scientific instrument, ensuring that results can be achieved consistently.

Understanding the Trade-offs

While powerful, the design of a muffle furnace introduces specific considerations that every user should understand.

Slower Heating and Cooling Cycles

Because the heat must first saturate the muffle chamber before being transferred to the sample, heating times can be slower than in direct-heating furnaces. Similarly, the heavy insulation means cool-down periods are naturally extended.

The Impact of Sample Placement

Although designed for uniformity, achieving perfect temperature homogeneity depends on correct use. Improper placement of a sample, especially if it is too large or touching a wall, can create minor temperature gradients and affect results.

Energy Consumption for Larger Models

The energy required to heat the internal volume and thermal mass of the muffle increases significantly with chamber size. For large-scale industrial applications, the operational cost is a direct trade-off against the furnace's processing capacity.

Making the Right Choice for Your Application

Selecting the right thermal processing tool depends entirely on your primary objective.

- If your primary focus is material purity and preventing contamination: A muffle furnace is the ideal choice due to the physical separation between the heating elements and your sample.

- If your primary focus is achieving highly reproducible thermal profiles: The combination of an isolated muffle design and modern digital controls makes this furnace a superior option.

- If your primary focus is maximum heating speed for robust materials: You may need to evaluate the trade-off in cycle time or consider a direct-radiation furnace if contamination is not a concern.

Understanding these core principles allows you to leverage the muffle furnace not just as a heat source, but as a precision instrument for achieving reliable, high-quality results.

Summary Table:

| Principle | Key Function | Benefit |

|---|---|---|

| Heat Generation | Uses electrical resistance in elements | Clean, efficient heating without combustion byproducts |

| Isolation | Muffle chamber separates sample from elements | Prevents contamination and ensures purity |

| Uniform Heat Transfer | Combines conduction, convection, radiation | Achieves even temperature distribution for reliable results |

Ready to elevate your lab's thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your precision and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?