To verify catalyst stability, a high-precision programmed heating system is essential because it eliminates thermal fluctuation as a variable during continuous testing. By maintaining a rigorous isothermal environment within the high-pressure reactor, researchers can attribute any drop in performance solely to the degradation of the catalyst, rather than unstable experimental conditions.

In the context of single-atom catalysts, even minor temperature deviations can skew data and mask true catalytic behavior. Precise thermal control is the only way to definitively prove a material’s stability for potential industrial application.

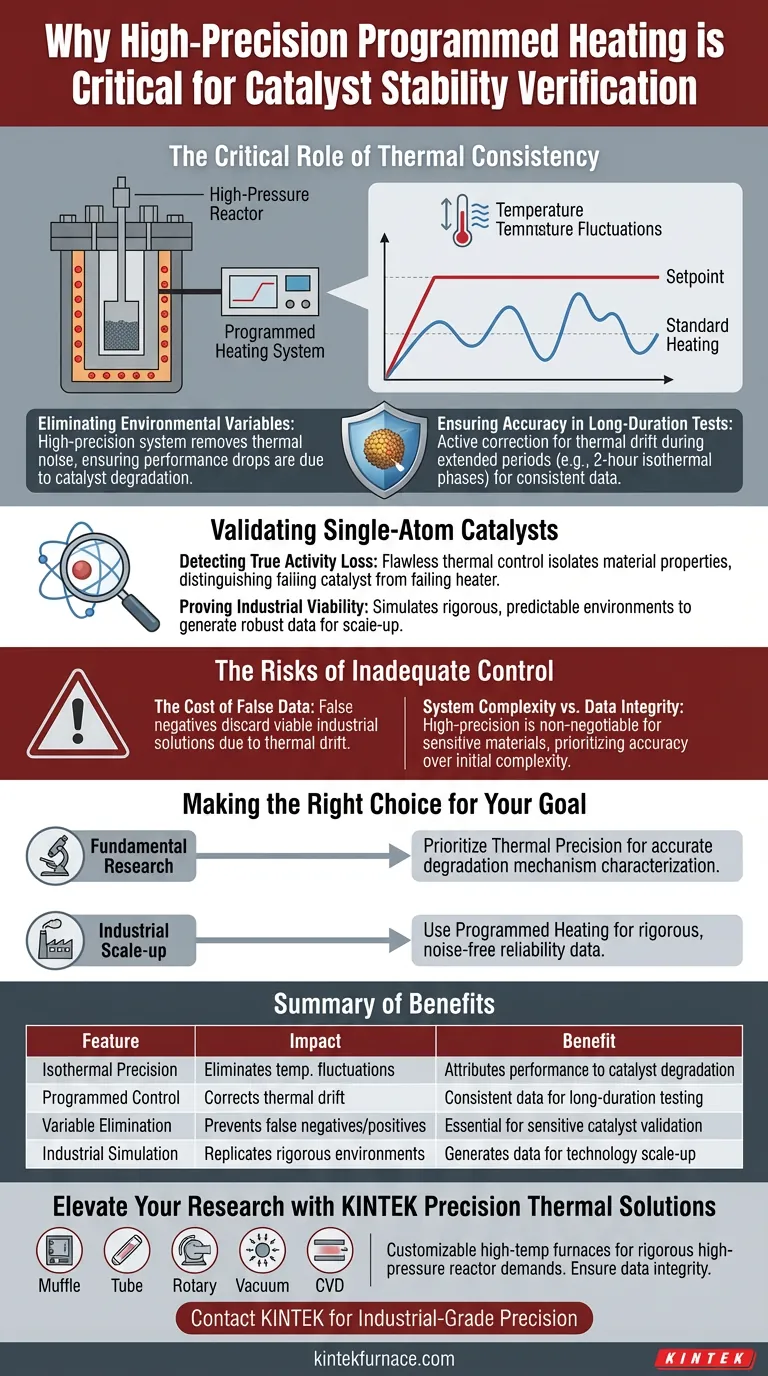

The Critical Role of Thermal Consistency

Eliminating Environmental Variables

In continuous multi-round cycle stability tests, the goal is to isolate the catalyst's inherent lifespan.

Temperature fluctuations introduce noise into this data. If the temperature inadvertently drops, reaction rates typically slow, mimicking catalyst deactivation. Conversely, temperature spikes can artificially inflate performance.

A high-precision system ensures these variables are removed, providing a "clean" background for the experiment.

Ensuring Accuracy in Long-Duration Tests

Stability verification often requires long experimental phases, such as 2-hour isothermal periods.

Standard heating elements may drift over these extended durations. A programmed system actively corrects for this, locking the temperature at the set point throughout the entire cycle.

Validating Single-Atom Catalysts

Detecting True Activity Loss

Single-atom catalysts are highly sensitive materials. To determine if their activity effectively diminishes over repeated cycles, the testing environment must be flawless.

If the heating system allows variance, it becomes impossible to distinguish between a failing catalyst and a failing heater. Precision equipment ensures that any observed loss in activity is a true reflection of the catalyst's material properties.

Proving Industrial Viability

The ultimate goal of these tests is to demonstrate the potential stability of the catalytic system for industrial applications.

Industrial processes rely on predictable, long-term performance. By using high-precision programmed heating to simulate these rigorous conditions without error, researchers generate the robust data needed to justify scaling up the technology.

The Risks of Inadequate Control

The Cost of False Data

Using standard or low-precision heating in high-pressure reactors introduces a significant risk of false negatives.

If a stable catalyst appears unstable due to thermal drift, a potentially viable industrial solution may be discarded.

System Complexity

While high-precision systems add complexity and cost to the reactor setup, they are a non-negotiable requirement for sensitive materials like single-atom catalysts. The trade-off is higher upfront equipment demands in exchange for data integrity.

Making the Right Choice for Your Goal

To ensure your stability data is accepted by the scientific and industrial communities, consider the following:

- If your primary focus is fundamental research: Prioritize thermal precision to accurately characterize the degradation mechanism of single-atom sites without environmental interference.

- If your primary focus is industrial scale-up: Use programmed heating to generate the rigorous, noise-free reliability data required to prove long-term viability to stakeholders.

The integrity of your stability test relies as much on the precision of your heating control as it does on the chemistry of your reactor.

Summary Table:

| Feature | Impact on Catalyst Testing | Benefit for Research/Industry |

|---|---|---|

| Isothermal Precision | Eliminates temperature fluctuations as a variable. | Attributes performance drops solely to catalyst degradation. |

| Programmed Control | Corrects thermal drift during long-duration cycles. | Provides consistent data for 2h+ isothermal testing periods. |

| Variable Elimination | Prevents false negatives/positives in activity loss. | Essential for sensitive single-atom catalyst validation. |

| Industrial Simulation | Replicates rigorous, predictable environments. | Generates the robust data needed for technology scale-up. |

Elevate Your Research with Precision Thermal Solutions

Ensure your catalyst stability data is beyond reproach with high-performance heating systems. At KINTEK, we understand that data integrity depends on environmental control. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet the rigorous demands of your high-pressure reactor setups.

Don't let thermal drift compromise your results. Contact KINTEK today to discuss how our customizable heating solutions can bring industrial-grade precision to your laboratory.

Visual Guide

References

- Bin Li, Yunjie Ding. Water-participated mild oxidation of ethane to acetaldehyde. DOI: 10.1038/s41467-024-46884-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key requirements for steel materials in high-speed rail, nuclear power, and aerospace industries? Unlock High-Performance Steel Solutions

- What is the purpose of the constant-temperature circulation phase? Ensure Moso Bamboo Integrity with KINTEK Solutions

- What is the primary function of carbonization equipment? Master Biomass to Fuel Conversion with Precision

- What is the function of a laboratory oven in activated carbon preparation? Ensure Superior Material Stability

- What is the disadvantage of dental ceramic? Weighing Cost, Strength, and Aesthetics

- What is the primary purpose of high-temperature pyrolysis? Unlock Superior PFAS Removal with Enhanced Hydrophobicity

- What additional techniques are used in activated sintering? Boost Efficiency with Advanced Chemical Methods

- How does a laboratory furnace operate? Master Heating Principles for Your Lab