At its core, a high melting point is desirable for a ceramic heating element because it directly determines the element's maximum operating temperature. This allows it to generate intense heat safely and efficiently without melting, which would cause catastrophic failure.

The fundamental purpose of a heating element is to get extremely hot without destroying itself. A high melting point provides the essential safety margin, ensuring the element remains physically stable and functional well above its required operating temperature.

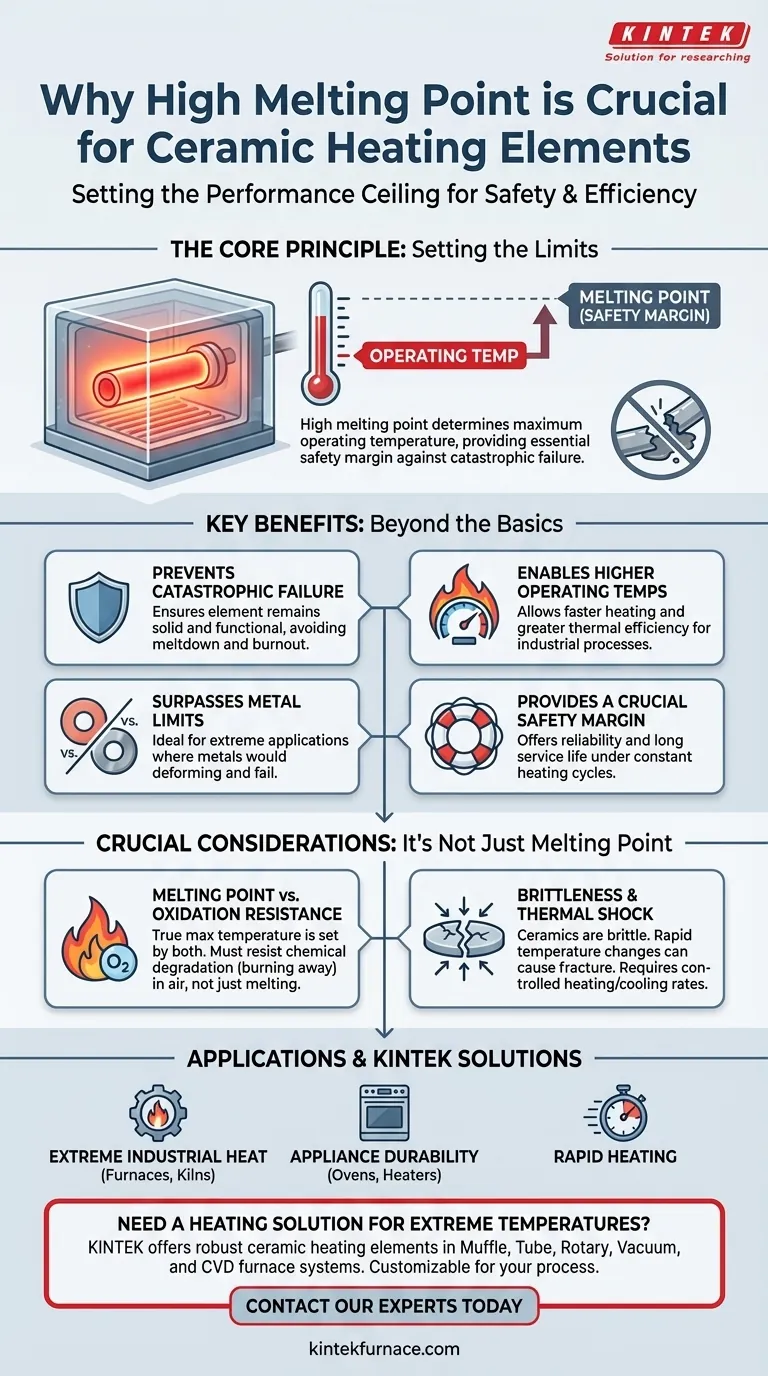

The Core Principle: Setting the Performance Ceiling

The melting point of a material is a fundamental physical limit. For a component designed specifically to generate heat, this limit is the most critical factor defining its performance and reliability.

Preventing Catastrophic Failure

The most common failure mode for any heating element is "burnout," which occurs when it reaches a temperature that compromises its structural integrity.

A high melting point ensures the ceramic remains a stable solid, even when glowing red-hot. This prevents the element from deforming, liquefying, and ultimately breaking the electrical circuit.

Enabling Higher Operating Temperatures

The primary advantage of a high operating temperature is efficiency. The hotter an element can get, the more thermal energy it can radiate and conduct to its surroundings.

This allows devices like industrial furnaces, kilns, and high-performance ovens to reach their target temperatures quickly and effectively.

The Clear Advantage Over Metals

While many metals are excellent conductors, their relatively lower melting points create a performance ceiling that ceramics easily surpass.

This is why ceramics are the material of choice for the most demanding, high-temperature applications where metallic elements would simply melt and fail.

Understanding the Key Considerations

A high melting point is the most important characteristic, but it doesn't work in isolation. Other material properties are critical for real-world performance.

Melting Point vs. Oxidation Resistance

The true maximum operating temperature is set by two factors: the melting point and the material's resistance to oxidation.

In the presence of air, some materials can chemically degrade or "burn away" at temperatures far below their melting point. A superior ceramic element must resist both heat and chemical attack.

Brittleness and Thermal Shock

The primary trade-off for the extreme temperature resistance of ceramics is their brittleness. Unlike metals that bend, ceramics can crack.

Engineers must design systems that heat and cool at controlled rates to avoid thermal shock, where rapid temperature changes can cause the element to fracture.

How to Apply This to Your Application

Choosing the right element requires matching its material properties to the demands of the task.

- If your primary focus is extreme industrial heat (furnaces, kilns): A high melting point is the non-negotiable starting point for both operational performance and safety.

- If your primary focus is appliance durability (ovens, water heaters): A high melting point provides a crucial safety margin and ensures a long service life under constant heating and cooling cycles.

- If your primary focus is rapid heating: Select an element that can not only reach a high temperature quickly but is also engineered to withstand the thermal shock of doing so.

Ultimately, a high melting point is the foundational property that allows a ceramic heating element to fulfill its core purpose safely and reliably.

Summary Table:

| Key Benefit | Why It Matters |

|---|---|

| Prevents Catastrophic Failure | Ensures the element remains solid and functional, avoiding meltdown. |

| Enables Higher Operating Temperatures | Allows for faster heating and greater thermal efficiency. |

| Provides a Crucial Safety Margin | Offers reliability and a long service life under intense heat. |

| Surpasses Metal Element Limits | Ideal for extreme applications where metals would fail. |

Need a heating solution that can handle extreme temperatures?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all featuring robust ceramic heating elements designed for high-temperature performance and durability. Our lab high-temp furnaces are customizable to meet your unique process requirements.

Contact our experts today to discuss how our high-performance heating solutions can enhance your application's safety and efficiency.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency