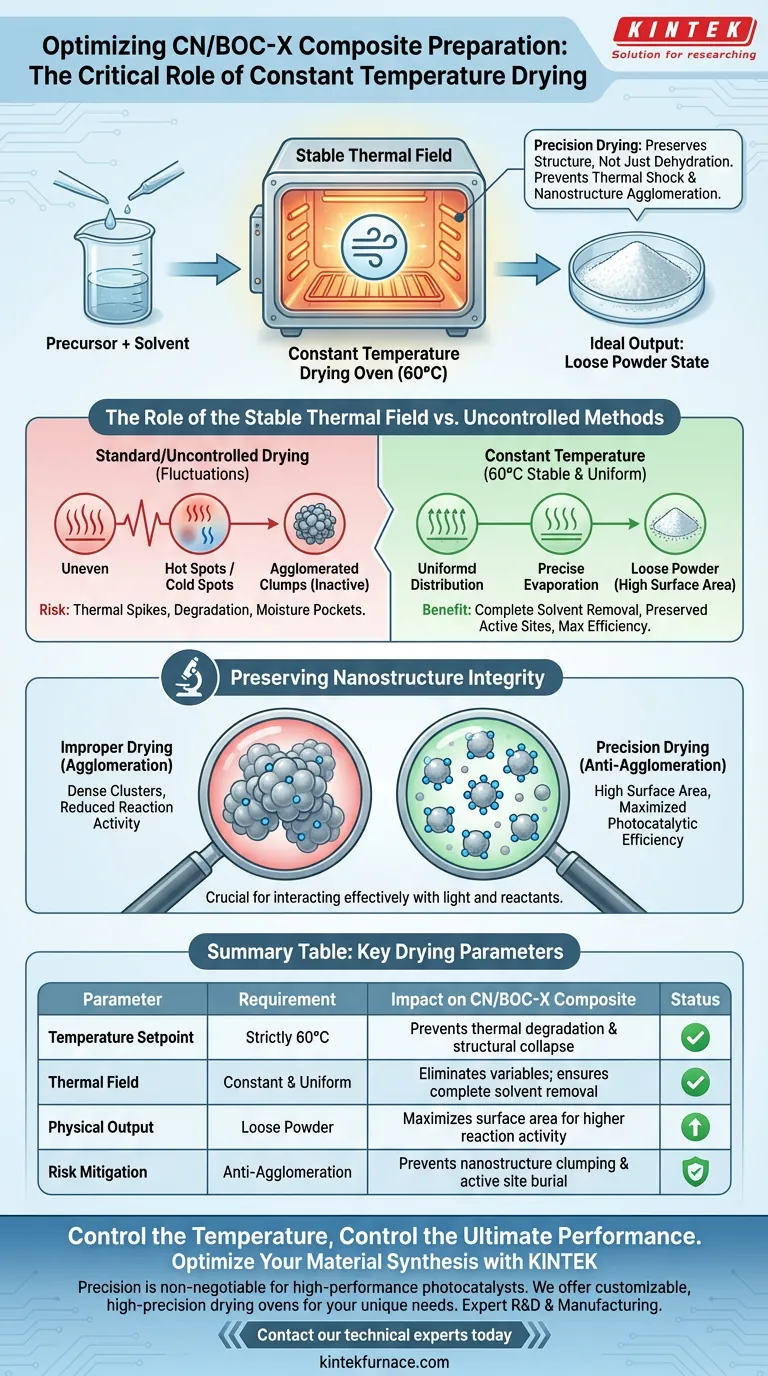

A constant temperature drying oven is critical for preserving the structural integrity and chemical potential of CN/BOC-X composite materials. By maintaining a strictly controlled thermal field at 60°C, the equipment ensures the complete removal of residual water and washing solvents without thermally shocking the material. This precise evaporation process is the defining factor in achieving a loose powder state rather than a chemically inactive, clumped aggregate.

Precision drying is not merely a dehydration step; it is a structural preservation technique. By preventing nanostructure agglomeration during solvent evaporation, the constant temperature process directly protects the material's surface area and maximizes its final photocatalytic efficiency.

The Role of the Stable Thermal Field

Eliminating Variables

The preparation of CN/BOC-X composites involves sensitive chemical structures.

A constant temperature oven eliminates thermal fluctuations that occur with standard drying methods.

By locking the environment to 60°C, you ensure that every part of the sample experiences the exact same energy input.

Complete Solvent Removal

After the washing phase, residual water and solvents remain trapped within the material matrix.

If these are not removed uniformly, they can interfere with the material's final chemical composition.

The constant thermal field guarantees that these impurities are fully evaporated, leaving behind only the pure composite structure.

Preserving Nanostructure Integrity

Preventing Agglomeration

The most significant risk during the drying phase is unintended agglomeration.

As moisture leaves the material, surface tension can force nanoparticles to pull together and clump.

A controlled, constant drying rate minimizes these forces, preventing the nanostructures from collapsing into dense clusters.

Ensuring a Loose Powder State

For a photocatalyst to be effective, it must exist as a loose, fine powder.

The constant temperature oven facilitates this texture by drying the material gently and evenly.

This "loose" state creates a high surface area, which is physically required for the material to interact with light and reactants effectively.

Understanding the Risks of Improper Drying

The Cost of Thermal Spikes

Using uncontrolled heating sources (like standard ovens or hot plates) introduces thermal gradients.

"Hot spots" can degrade the chemical structure of the CN/BOC-X composite, while "cold spots" leave behind moisture pockets.

Impact on Reaction Activity

The physical state of the material dictates its performance.

If the drying process fails to prevent agglomeration, the active sites of the photocatalyst become buried inside large clumps.

This directly reduces the "reaction activity" of the final product, rendering the synthesis process less effective regardless of the chemical precursors used.

Making the Right Choice for Your Goal

To maximize the quality of your CN/BOC-X composite preparation, align your drying protocol with your specific performance metrics.

- If your primary focus is Structural Fidelity: strict adherence to the 60°C setpoint is required to stabilize nanostructures without inducing thermal degradation.

- If your primary focus is High Reaction Activity: monitor the physical output for a "loose powder" consistency, as this texture confirms the prevention of agglomeration and maximum surface area availability.

Control the temperature during drying, and you control the ultimate performance of your material.

Summary Table:

| Drying Parameter | Requirement | Impact on CN/BOC-X Composite |

|---|---|---|

| Temperature Setpoint | Strictly 60°C | Prevents thermal degradation and structural collapse |

| Thermal Field | Constant & Uniform | Eliminates variables; ensures complete solvent removal |

| Physical Output | Loose Powder | Maximizes surface area for higher reaction activity |

| Risk Mitigation | Anti-Agglomeration | Prevents nanostructure clumping and active site burial |

Optimize Your Material Synthesis with KINTEK

Precision is the foundation of high-performance photocatalysts. At KINTEK, we understand that maintaining a stable thermal field is non-negotiable for preserving nanostructure integrity. Backed by expert R&D and manufacturing, we offer high-precision drying ovens, Muffle, Tube, and Vacuum systems—all customizable to ensure your CN/BOC-X composites achieve maximum surface area and reaction activity.

Ready to elevate your lab's research results? Contact our technical experts today to find the perfect thermal solution for your unique synthesis needs.

Visual Guide

References

- Jianhua Hou, Xiaozhi Wang. Grinding preparation of 2D/2D g-C3N4/BiOCl with oxygen vacancy heterostructure for improved visible-light-driven photocatalysis. DOI: 10.1007/s44246-023-00089-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of a laboratory vacuum drying oven in alpha-K3[CuIO6]·4H2O synthesis? Protect Crystal Integrity

- How are impurity levels controlled during tantalum powder synthesis? Master High-Purity Magnesiothermic Reduction

- Why do Axial Flame Burners produce high NOx? Managing Thermal Intensity in Oxygen-Enhanced Combustion

- What role does the annealing process play in the post-treatment of stir-cast aluminum matrix composites? | KINTEK

- Why is uniform thermal distribution critical for silica nanoparticle synthesis? Achieve 100% Phase Transformation

- What are the advantages of combining vacuum hot rolling with small hole vacuuming? High-Bonding Clad Plate Production

- What is the role of mortar grinding combined with heat gun processing in catalyst synthesis? Achieving PtCln Dispersion

- Why is a vacuum desiccator essential for studying geopolymer porosity? Achieve Precise Material Characterization