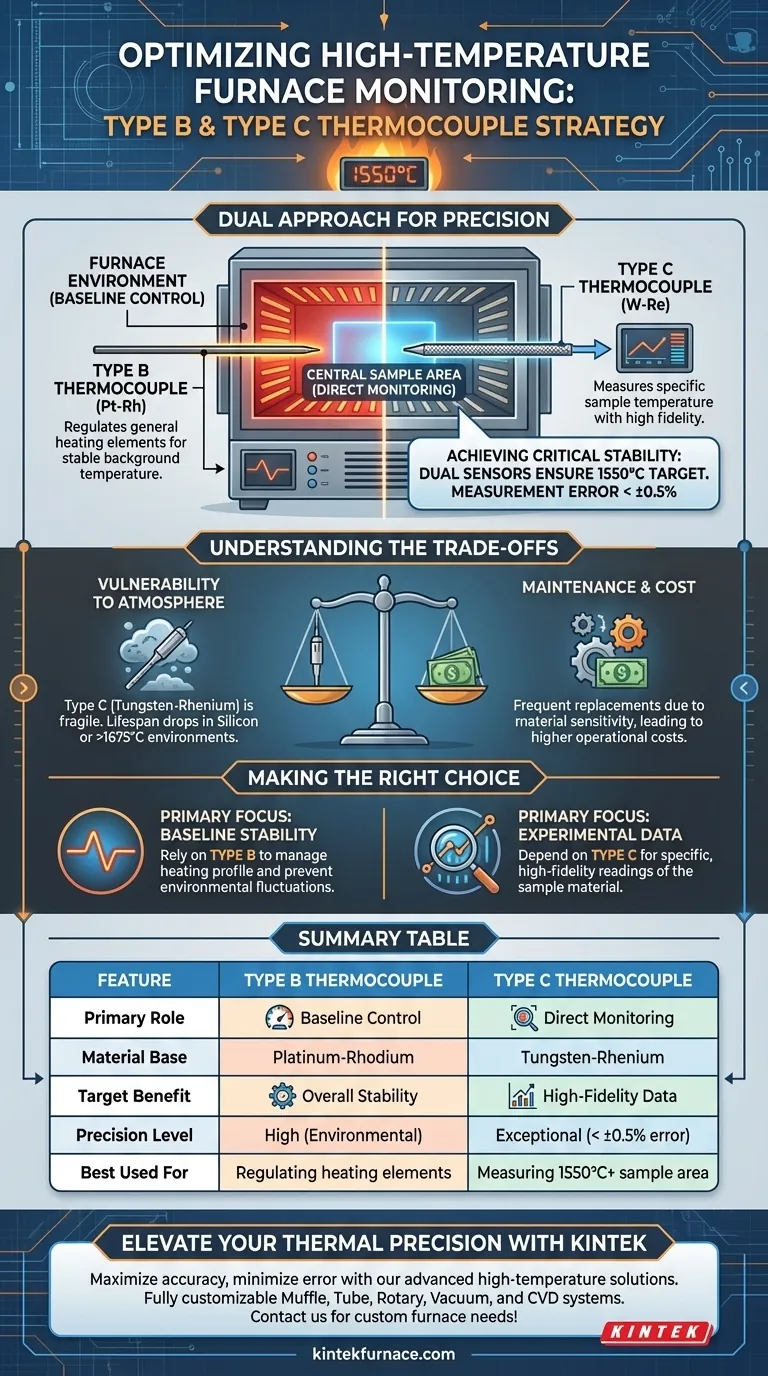

The combination of Type B and Type C thermocouples is a strategic engineering choice designed to separate environmental control from specific sample monitoring. To ensure experiment integrity at extreme temperatures, the Type B thermocouple regulates the general furnace environment, while the Type C thermocouple directly measures the temperature of the central sample area. This dual approach ensures the critical 1550°C target is maintained with exceptional precision.

The core advantage of this configuration is the reduction of measurement error to less than ±0.5%. By decoupling the furnace's baseline control from the sample's specific data collection, researchers can maintain the strict thermal stability required for studying sensitive properties like slag viscosity.

Optimizing Accuracy Through Sensor Specialization

Using a single sensor for both furnace control and sample data can lead to discrepancies. Assigning distinct roles to Type B and Type C thermocouples solves this problem.

Type B for Baseline Environmental Control

The Type B thermocouple acts as the primary regulator for the furnace's heating elements. Its job is to maintain the "background" temperature of the chamber, ensuring the overall environment remains stable and consistent.

Type C for Direct Sample Monitoring

The Type C thermocouple provides the granular data researchers actually need. It is positioned to monitor the central sample area directly, offering a precise reading of the material's temperature rather than just the surrounding air.

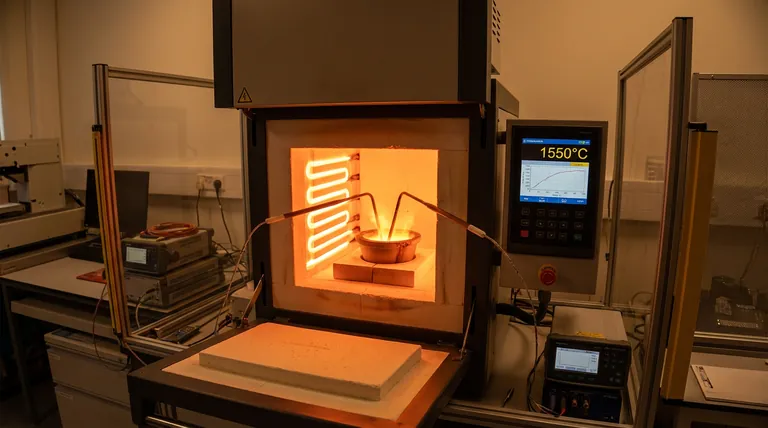

Achieving Critical Stability

For high-temperature experiments, such as those conducted at 1550°C, temperature fluctuations can ruin data regarding material viscosity. The combined data from these two sensors allows the system to hold the temperature constant with minimal error.

Understanding the Trade-offs

While this combination offers superior accuracy, it introduces specific challenges regarding durability and cost that must be managed.

Vulnerability to Atmosphere

Type C thermocouples (typically Tungsten-Rhenium) are highly effective at extreme heat but can be fragile in certain atmospheres. If the furnace environment contains silicon or reaches temperatures near 1675°C, the lifespan of these sensors drops significantly.

Maintenance and Cost Implications

Because of their material sensitivity, Tungsten-based thermocouples may last only a few cycles in aggressive environments. This necessitates frequent replacements, making this high-precision setup more expensive and maintenance-heavy than lower-temperature alternatives.

Making the Right Choice for Your Goal

When designing or operating a high-temperature furnace, understand how to weigh the function of each sensor type.

- If your primary focus is baseline stability: Rely on the Type B thermocouple to manage the furnace's general heating profile and prevent environmental fluctuations.

- If your primary focus is experimental data: Depend on the Type C thermocouple for the specific, high-fidelity temperature readings of the sample material itself.

By harmonizing these two sensor types, you effectively bridge the gap between broad environmental control and precise data acquisition.

Summary Table:

| Feature | Type B Thermocouple | Type C Thermocouple |

|---|---|---|

| Primary Role | Baseline Environmental Control | Direct Sample Monitoring |

| Material Base | Platinum-Rhodium | Tungsten-Rhenium |

| Target Benefit | Overall Furnace Stability | High-Fidelity Data Collection |

| Precision Level | High (Environmental) | Exceptional (< ±0.5% error) |

| Best Used For | Regulating heating elements | Measuring 1550°C+ sample area |

Elevate Your Thermal Precision with KINTEK

Maximize your experimental accuracy and minimize measurement error with our advanced high-temperature solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific research requirements. Whether you need specialized thermocouple configurations for slag viscosity studies or robust furnace environments for material synthesis, our engineers are ready to help.

Ready to optimize your lab's high-temperature performance? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Erdenebold Urtnasan, Jei‐Pil Wang. Artificial Slags with Modulated Properties for Controlled Nickel Dissolution in Smelting Process. DOI: 10.1007/s12666-024-03304-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the characteristics of Molybdenum Disilicide (MoSi2) as a heating element? Unlock Extreme Heat for Your Lab

- How are SiC heating elements being utilized in residential applications? Discover Premium Home Heating Solutions

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the key properties of silicon carbide that make it suitable for heating elements? Discover Its High-Temp Durability and Efficiency

- Why is a ceramic substrate with an integrated heating device necessary for GaS ammonia sensors? Ensure Precise Testing

- What are the common materials used for heating elements in industrial furnaces? Optimize Your Furnace Performance

- Why do heating coils in high-temp electric furnaces require power regulators? Ensure Precision in Metal Processing

- Which heating element is most effective? The definitive guide to choosing the right material for your application.