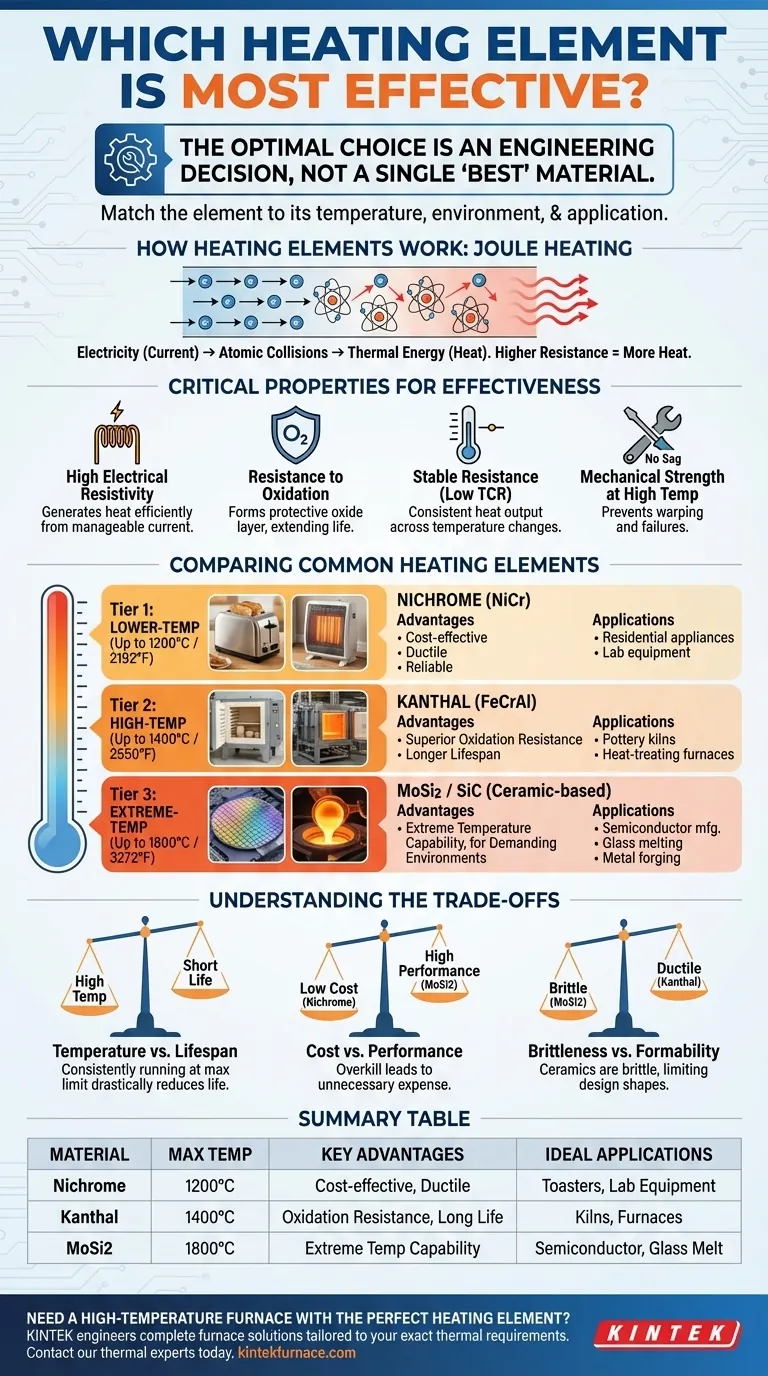

The most effective heating element is the one best matched to its specific operating temperature, environment, and application. For lower-temperature needs up to 1200°C (2192°F), Nichrome is the standard. For general-purpose high-temperature applications up to 1400°C (2550°F), Kanthal (FeCrAl) is superior. For extreme industrial heat up to 1800°C (3272°F), specialized materials like Molybdenum Disilicide (MoSi2) are required.

The concept of a single "most effective" heating element is a misconception. The optimal choice is not a specific material, but a careful engineering decision based on a trade-off between the required temperature, the element's resistance to chemical decay, and its mechanical stability.

How Heating Elements Work: The Principle of Resistance

From Electricity to Heat

A heating element functions by converting electrical energy into thermal energy through a process known as Joule heating.

When an electric current flows through a material, its electrons collide with the atoms of the conductor. These countless collisions create atomic-scale friction, which manifests as heat.

The amount of heat generated is determined by the material's electrical resistance. Higher resistance forces more energy to be dissipated as heat for a given current, making it the most critical property in element design.

Why Material Choice Is Critical

Different materials possess different levels of intrinsic electrical resistance. An ideal heating element material has high resistivity, allowing it to generate significant heat efficiently without requiring excessive current or length.

This is why simple conductors like copper are poor heating elements, while specialized alloys are excellent. The material's fundamental properties dictate its performance, lifespan, and suitability for a given task.

Key Properties of an Effective Heating Element

Beyond simple resistance, several properties determine a material's effectiveness and longevity in a heating application.

High Electrical Resistivity

A material with high resistivity generates substantial heat from a manageable electric current. This allows for more compact and efficient heater designs.

Resistance to Oxidation

At high temperatures, most metals react rapidly with oxygen in the air, leading to corrosion and eventual failure.

Effective heating alloys like Kanthal and Nichrome form a thin, protective layer of oxide on their surface. This layer shields the underlying material from further degradation, dramatically extending the element's service life.

Stable Resistance Across Temperatures

The resistance of some materials can change significantly as they heat up, leading to unstable and unpredictable heat output.

A low temperature coefficient of resistance (TCR) is highly desirable. It ensures that the element produces a consistent amount of heat as it cycles from cold to its operating temperature.

Mechanical Strength at High Temperatures

Heating elements must maintain their shape and strength when glowing hot. Poor mechanical stability can lead to sagging, warping, or stretching, known as "creep."

This can cause the element to make contact with other components, creating a short circuit and catastrophic failure. Durable materials are essential for reliability, especially in industrial furnaces and kilns.

Comparing Common Heating Element Materials

The choice of material is primarily driven by the maximum required operating temperature.

Nichrome (NiCr) Alloys

Nichrome is the workhorse for many residential and light commercial applications. It's ductile, easy to form, and reliable for temperatures up to 1200°C (2192°F).

You will find Nichrome in devices like toasters, space heaters, and laboratory equipment where extreme heat is not the primary requirement.

Kanthal (FeCrAl) Alloys

Kanthal, an alloy of iron, chromium, and aluminum, is the standard for general-purpose, high-temperature heating. It offers superior oxidation resistance compared to Nichrome.

With a maximum operating temperature of 1400°C (2550°F), it is the dominant material used in pottery kilns and industrial heat-treating furnaces.

Molybdenum Disilicide (MoSi2) and Silicon Carbide (SiC)

These are ceramic-based materials designed for the most demanding industrial environments. MoSi2 can operate continuously at temperatures up to 1800°C (3272°F).

Due to their extreme temperature capabilities, they are used in semiconductor manufacturing, glass melting, and metal forging processes where traditional metallic elements would quickly fail.

Understanding the Trade-offs

Selecting a heating element involves balancing performance with practical limitations. There is no perfect material, only the right one for the job.

Temperature vs. Lifespan

An element's maximum temperature rating is not its ideal operating point. Consistently running an element at its absolute limit will drastically reduce its service life.

For long-term reliability, it is standard practice to select a material whose maximum rating is significantly higher than your intended operating temperature.

Material Cost vs. Performance

Performance comes at a price. Nichrome is relatively inexpensive, while Kanthal is moderately more. Extreme-temperature materials like MoSi2 are an order of magnitude more expensive.

Choosing a material that is overkill for your temperature needs results in unnecessary expense.

Brittleness and Formability

Metallic alloys like Nichrome and Kanthal are ductile and can be easily wound into coils or formed into complex shapes.

In contrast, high-temperature ceramic materials like MoSi2 and SiC are often brittle and can only be manufactured in simpler shapes, like straight rods or U-bends. This can constrain the design of the heating chamber.

Making the Right Choice for Your Application

Your final decision should be guided by your primary operational goal.

- If your primary focus is residential appliances or lower-temperature tasks (up to 1200°C): Nichrome alloys offer the best balance of cost, durability, and ease of use.

- If your primary focus is general-purpose industrial furnaces and kilns (up to 1400°C): Kanthal (FeCrAl) alloys provide superior oxidation resistance and a longer service life at high heat.

- If your primary focus is extreme-temperature industrial processes (above 1400°C): Molybdenum Disilicide (MoSi2) or Silicon Carbide (SiC) are necessary, despite their higher cost and specific handling requirements.

By aligning the material's properties with your operational demands, you ensure reliable, efficient, and long-lasting performance.

Summary Table:

| Material | Max Operating Temp (°C) | Key Advantages | Ideal Applications |

|---|---|---|---|

| Nichrome (NiCr) | Up to 1200°C | Cost-effective, ductile, easy to form | Toasters, space heaters, lower-temperature lab equipment |

| Kanthal (FeCrAl) | Up to 1400°C | Superior oxidation resistance, long service life | Pottery kilns, industrial heat-treating furnaces |

| Molybdenum Disilicide (MoSi2) | Up to 1800°C | Extreme temperature capability | Semiconductor manufacturing, glass melting, metal forging |

Need a High-Temperature Furnace with the Perfect Heating Element?

Selecting the right heating element is critical for your furnace's performance and longevity. At KINTEK, we don't just supply standard elements—we engineer complete furnace solutions tailored to your exact thermal requirements.

Why choose KINTEK?

- Expert Guidance: Our engineers will help you select the optimal heating element material—from Nichrome and Kanthal to MoSi2—based on your target temperature, atmosphere, and process goals.

- Superior Performance: Leveraging our exceptional R&D and in-house manufacturing, we build furnaces that maximize the lifespan and efficiency of your chosen element.

- Deep Customization: Whether you need a standard Muffle Furnace or a complex custom CVD/PECVD System, we design our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces around your unique application.

Ensure your lab operates at peak efficiency with a furnace built for your specific needs.

Contact our thermal experts today for a consultation and let us help you build a more effective heating solution.

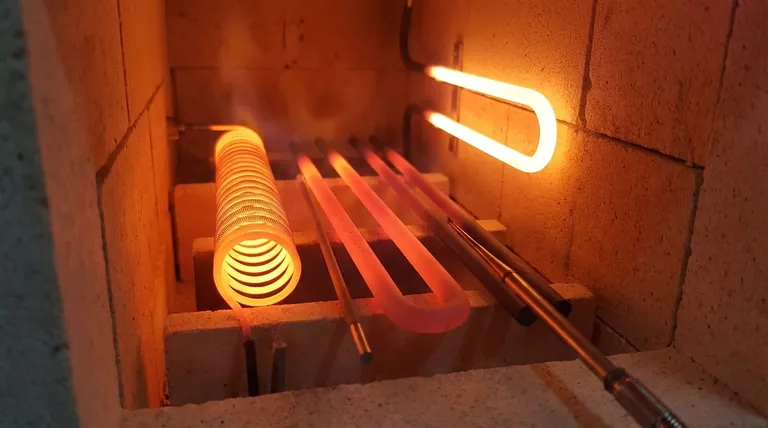

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance