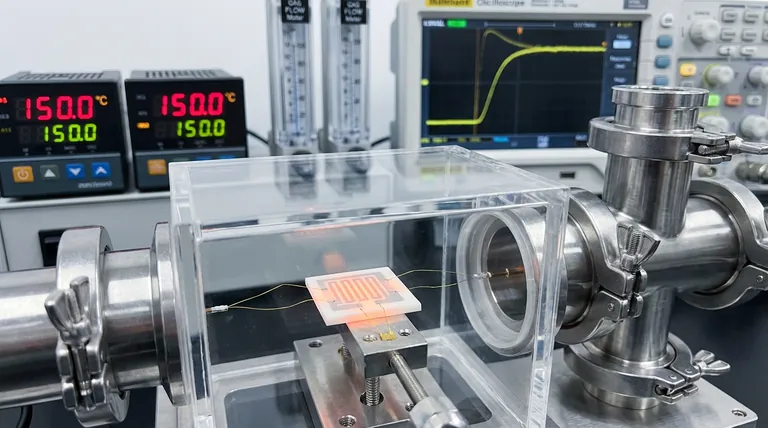

Precise thermal management is the fundamental requirement for accurate Gallium Sulfide (GaS) sensor testing. A ceramic substrate with an integrated heating device—typically a platinum resistor on high-purity alumina—is necessary because the interaction between ammonia and the GaS surface is driven by heat. This setup provides the stable, elevated temperatures (often around 150°C) required to optimize gas adsorption kinetics and ensure the sensor recovers quickly for dynamic measurement.

Effective ammonia sensing with Gallium Sulfide relies on finding a specific thermal "working window" where chemical reactions occur efficiently. Integrated heating transforms the substrate from a passive support structure into an active control mechanism that regulates sensitivity and recovery speed.

The Physics of Thermal Regulation

Driving Gas Adsorption Kinetics

The primary function of the heating device is to control the gas adsorption kinetics of the sensor. The reaction between ammonia molecules and the Gallium Sulfide material is not static; its speed and intensity change drastically with temperature.

By integrating a platinum heating resistor, you can maintain a precise temperature environment. This thermal energy is required to overcome the activation energy barriers that allow ammonia to chemically bind to the sensing surface.

Activating the Surface Oxide Layer

Gallium Sulfide sensors often feature a surface oxide layer that plays a critical role in detection. The behavior of this layer is highly temperature-dependent.

Without consistent heat, the interaction between this oxide layer and the target gas remains unpredictable. The ceramic substrate ensures that the surface chemistry remains active and consistent throughout the testing phase.

Optimizing Dynamic Response

Reducing Desorption Recovery Time

One of the biggest challenges in dynamic sensor testing is recovery time—how fast the sensor "clears" itself after detecting gas.

The integrated heater significantly shortens this desorption process. By maintaining an elevated temperature, the device provides the thermal energy needed to detach ammonia molecules from the surface, resetting the sensor for the next measurement.

Determining the Optimal Working Window

Every semiconductor sensor has a specific temperature range where it performs best. This is known as the optimal working window.

Using a substrate with precise temperature regulation allows you to sweep through different thermal conditions. This capability is essential for pinpointing the exact temperature that yields the highest signal-to-noise ratio for ammonia detection.

Understanding the Trade-offs

Complexity vs. Control

While integrated heating is necessary for performance, it adds complexity to the sensor architecture. You are no longer just managing a sensing material; you are managing a thermodynamic system.

Any fluctuation in the heating element can be misinterpreted as a change in gas concentration. Therefore, the precision of the platinum resistor and the purity of the alumina ceramic are non-negotiable for reliable data.

Power Consumption Considerations

Active heating requires continuous power. In a laboratory setting, this is negligible, but for portable applications, the requirement to maintain 150°C can impact the energy budget.

However, the trade-off is unavoidable: without this energy expenditure, the chemical adsorption rates drop, and the sensor becomes sluggish and inaccurate.

Making the Right Choice for Your Goal

To maximize the effectiveness of your Gallium Sulfide sensor testing, align your thermal strategy with your specific data requirements.

- If your primary focus is Sensitivity: Prioritize finding the specific temperature that maximizes the chemical adsorption of ammonia on the oxide layer.

- If your primary focus is Speed: Increase the operating temperature within the safe range to accelerate desorption and shorten the recovery time between tests.

Control the temperature, and you control the reliability of your data.

Summary Table:

| Feature | Role in GaS Ammonia Sensing | Benefit for Dynamic Testing |

|---|---|---|

| Integrated Pt Resistor | Precise temperature regulation | Stable thermal environment for consistent data |

| High-Purity Alumina | High-performance support base | Minimized thermal loss and chemical interference |

| Surface Activation | Lowers activation energy barriers | Optimizes ammonia adsorption on the oxide layer |

| Thermal Desorption | Accelerates gas molecule detachment | Significantly reduces recovery time between tests |

Elevate Your Sensor Research with KINTEK Precision

Maximize your GaS sensor performance with a thermodynamic setup built for accuracy. Backed by expert R&D and world-class manufacturing, KINTEK offers high-purity alumina substrates and customizable high-temp lab solutions—including Muffle, Tube, and Vacuum systems—tailored to your unique research needs.

Ready to optimize your thermal working window? Contact us today to discuss your project and see how our advanced heating solutions can streamline your testing workflow.

References

- Danil Bukhvalov, Antonio Politano. Self‐Assembled Gallium Sulfide (GaS) Heterostructures Enabling Efficient Water Splitting and Selective Ammonia Sensing. DOI: 10.1002/adfm.202507388

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- How do quartz halogen heating elements function and where are they used? Discover Rapid, Efficient Radiant Heat Solutions

- What is the primary function of electric heating elements? Convert Electricity to Reliable Heat Efficiently

- How does a K-type thermocouple ensure process reliability in lead-bismuth alloy separation? Master Thermal Precision

- What are the main differences in performance between MoSi2 and SiC heating elements? Choose the Right Element for Your High-Temp Needs

- What are the primary materials for ultra-high-temperature heating elements? Select the Right One for Your Lab

- What are the advantages of Iron-Chrome-Aluminum (FeCrAl) alloy for high-temperature applications? Superior Durability & Efficiency

- How can the service life of silicon carbide heating elements be prolonged? Extend Lifespan with Expert Tips

- What is watt-density and why is it important in heating element design? Ensure Efficiency and Longevity