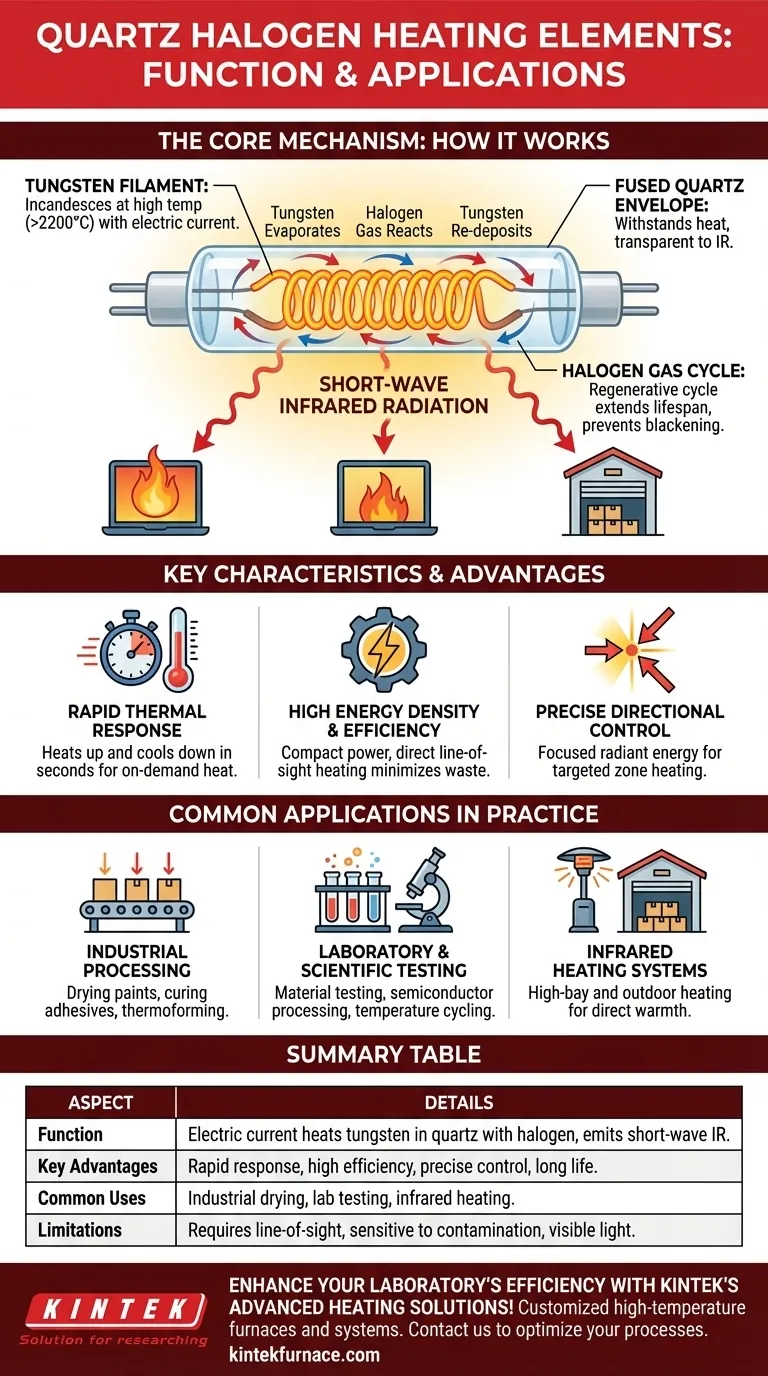

At its core, a quartz halogen heating element functions by passing an electric current through a tungsten filament encased in a fused quartz tube. This tube is filled with a halogen gas, which enables a regenerative chemical cycle that dramatically increases the element's lifespan and efficiency. The result is the emission of intense, short-wave infrared radiation that provides rapid, direct heat to objects.

The primary advantage of quartz halogen technology is not simply heat, but its delivery method: it provides near-instantaneous, highly efficient, and precisely directional radiant energy. This makes it a superior choice for applications where speed and control are more critical than heating ambient air.

The Core Mechanism: How Quartz Halogen Heaters Work

To understand where these heaters excel, you must first understand their three key components and the process that links them together.

The Tungsten Filament

The source of all energy is a coiled tungsten filament. When electrical current is applied, its high resistance causes it to incandesce at extremely high temperatures, often exceeding 2,200 °C (4,000 °F).

The Fused Quartz Envelope

The filament is housed inside a tube made of fused quartz. This material is essential for two reasons: it can withstand the immense operating temperatures without melting, and it is highly transparent to short-wave infrared energy, allowing the radiation to pass through with minimal loss.

The Halogen Gas Cycle

This is the critical innovation. The tube is filled with a small amount of a halogen gas (like iodine or bromine). At high temperatures, tungsten atoms evaporate from the filament—a process that would normally cause the filament to thin and the tube to blacken.

The halogen gas reacts with these evaporated tungsten atoms, forming a tungsten halide gas. This compound circulates until it drifts back toward the hot filament, where the intense heat breaks it down, re-depositing the tungsten back onto the filament. This regenerative cycle prevents blackening and significantly extends the element's operational life.

Short-Wave Infrared Radiation

The filament's high temperature produces primarily short-wave infrared (IR) energy. Unlike long-wave IR, which mostly heats the surface of an object, short-wave IR can penetrate many materials, heating them quickly and efficiently from within. This is "radiant heat," meaning it heats objects directly without needing to heat the air in between.

Key Characteristics and Advantages

The unique operating principle of quartz halogen elements gives them distinct advantages for specific industrial and scientific tasks.

Rapid Thermal Response

The filament has a very low thermal mass. This allows it to reach full operating temperature in seconds and cool down just as quickly, providing on-demand heat that is ideal for processes requiring rapid thermal cycling.

High Energy Density and Efficiency

These elements pack a significant amount of power into a compact form factor. Because they transfer energy via line-of-sight radiation, very little is wasted heating the surrounding air, making them exceptionally efficient for targeted heating tasks.

Precise Directional Control

The emitted infrared energy travels in straight lines, much like light. This allows it to be precisely focused and aimed using reflectors, enabling the heating of a specific zone on a product without affecting adjacent areas.

Understanding the Trade-offs

No technology is perfect for every scenario. Understanding the limitations of quartz halogen heaters is critical for correct application.

Sensitivity to Contamination

The quartz tube's surface must remain perfectly clean. Oils from fingerprints, dust, or other contaminants can burn into the surface, creating a "hot spot" that absorbs heat. This leads to devitrification—a structural change that makes the quartz brittle and opaque, causing premature failure.

Requirement for Line-of-Sight Heating

As a form of radiant heating, the element can only heat surfaces it can "see." Objects with complex geometries or shadowed areas may experience non-uniform heating unless multiple heaters or complex reflector systems are strategically placed.

Production of Visible Light

The high-temperature filament produces a bright, white-to-yellow glow in addition to infrared energy. While useful for visual confirmation that the element is working, this intense light can be an undesirable byproduct in light-sensitive applications.

Common Applications in Practice

The combination of speed, control, and efficiency makes these elements indispensable in several fields.

Industrial Processing

Quartz halogen heaters are used extensively for drying paints and coatings, curing adhesives, and thermoforming plastics. The rapid, penetrating heat accelerates production cycles significantly compared to convection ovens.

Laboratory and Scientific Testing

In laboratory settings, the precise on/off control allows for repeatable, rapid temperature cycling. This is crucial for equipment used in material stress testing, semiconductor processing, and temperature-sensitive chemical experiments.

Infrared Heating Systems

For both commercial and industrial spaces, these elements are used in high-bay heaters and outdoor patio heaters. Their ability to heat people and objects directly is far more effective in large, drafty areas than attempting to heat the entire volume of air with a convection system.

Making the Right Choice for Your Application

Use these guidelines to determine if quartz halogen technology aligns with your goal.

- If your primary focus is process speed and precision: Quartz halogen is an excellent choice for automated processes where rapid, repeatable heating of a specific target is required.

- If your primary focus is uniform ambient air heating: A traditional convection heater that circulates warm air will be a more effective and economical solution.

- If your primary focus is ruggedness in a dirty environment: Consider that the quartz tube is fragile and sensitive; a more robust metal-sheathed element may be better suited unless you can ensure a clean operating environment.

Ultimately, selecting a quartz halogen heater is a decision for targeted, on-demand radiant energy where control and speed are paramount.

Summary Table:

| Aspect | Details |

|---|---|

| Function | Electric current heats tungsten filament in quartz tube with halogen gas, emitting short-wave IR for direct radiant heat. |

| Key Advantages | Rapid thermal response, high energy efficiency, precise directional control, long lifespan via regenerative cycle. |

| Common Uses | Industrial drying/curing, lab testing, infrared heating systems for targeted applications. |

| Limitations | Requires line-of-sight, sensitive to contamination, produces visible light. |

Enhance your laboratory's efficiency with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs. Contact us today to discuss how our tailored solutions can optimize your heating processes and accelerate your research!

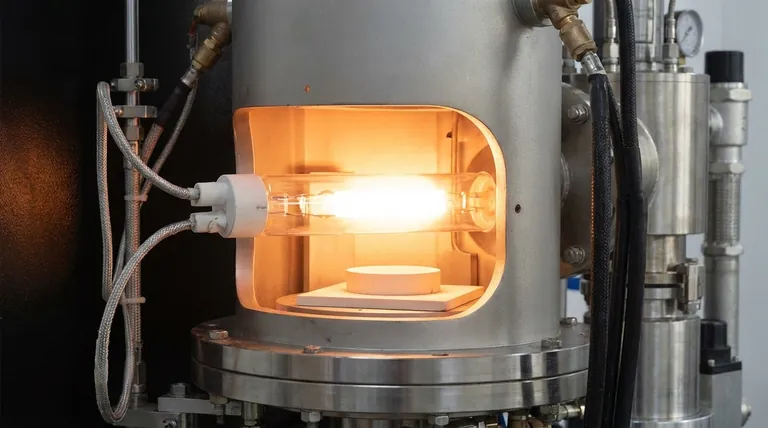

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance