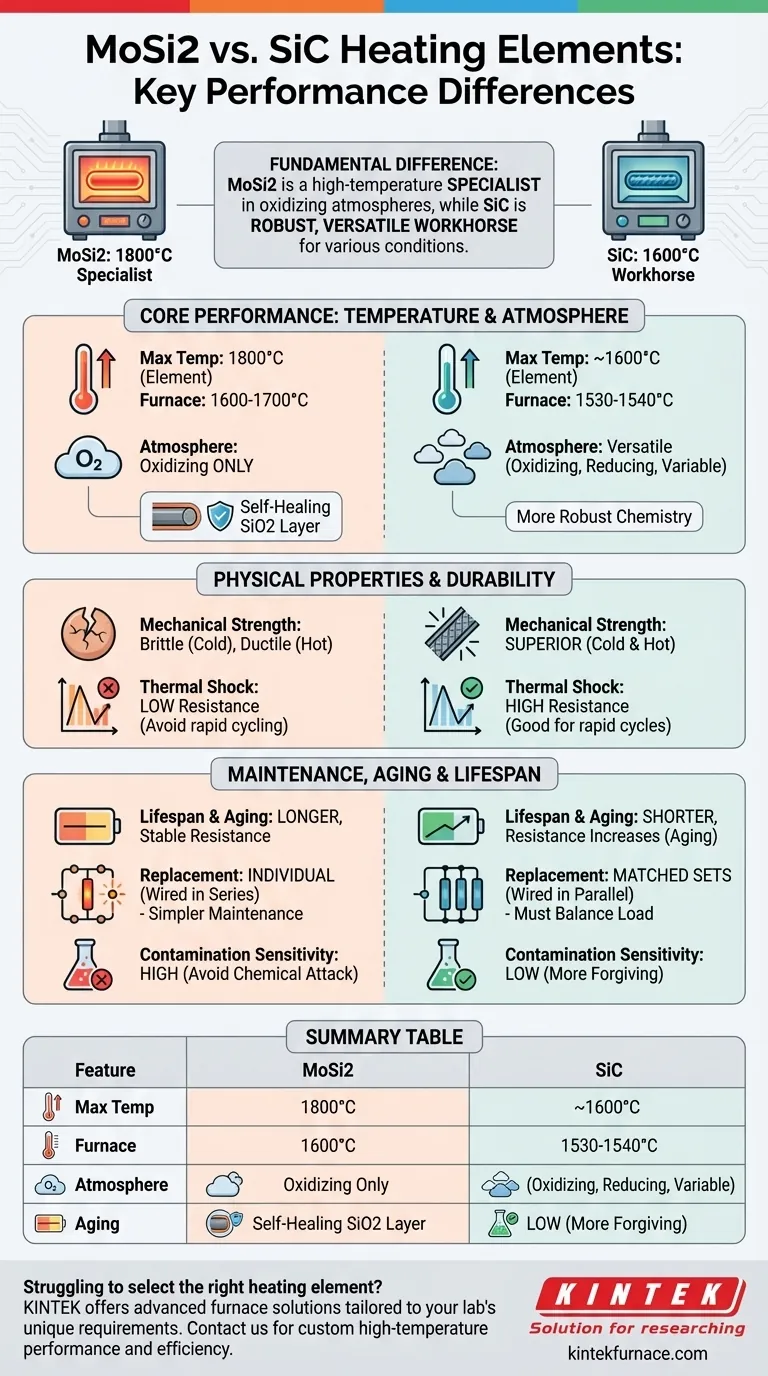

The fundamental difference between Molybdenum Disilicide (MoSi2) and Silicon Carbide (SiC) heating elements lies in their optimal operating windows. MoSi2 is a high-temperature specialist, excelling in oxidizing atmospheres up to 1800°C. In contrast, SiC is a more robust and versatile workhorse, offering superior mechanical strength and performance in various atmospheres up to 1600°C.

The choice is not about which material is universally "better," but which is precisely engineered for your specific application. MoSi2 is for extreme heat in clean, oxidizing environments, while SiC is for durability, versatility, and thermal cycling in a wider range of conditions.

Core Performance Metrics: Temperature and Atmosphere

Your first decision point must be the required temperature and the furnace's atmospheric conditions. These two factors are the most significant differentiators between MoSi2 and SiC.

Maximum Operating Temperature

MoSi2 elements are the clear choice for the highest temperature ranges. They can operate at element temperatures up to 1800°C, allowing for furnace chamber temperatures between 1600°C and 1700°C. Their performance and lifespan are best when consistently run above 1500°C.

SiC elements have a lower maximum operating temperature, typically around 1600°C. This translates to a maximum furnace chamber temperature of about 1530°C to 1540°C.

Atmospheric Versatility

MoSi2 elements are specialists. They depend on an oxidizing atmosphere (like air) to form a protective, self-healing layer of silica (SiO2) on their surface. This layer is what gives them their exceptional high-temperature stability.

SiC elements are generalists. They are inherently more robust and perform reliably across a broader range of conditions, including oxidizing, reducing, or variable atmospheres. This makes them a more versatile choice if your process chemistry is not strictly controlled.

Physical Properties and Durability

Beyond temperature and atmosphere, the physical characteristics of the elements dictate their longevity and suitability for different mechanical stresses.

Thermal Shock and Mechanical Strength

SiC has superior mechanical strength and much better resistance to thermal shock. This makes it the preferred option for applications involving rapid heating and cooling cycles.

MoSi2 is more brittle at room temperature but becomes more ductile at high operating temperatures. It is less suited for processes with frequent or rapid thermal cycling.

Aging and Lifespan

SiC elements experience an increase in electrical resistance as they age. This aging process means their power output decreases over time and contributes to a generally shorter lifespan compared to MoSi2 in high-heat applications.

MoSi2 elements maintain a more stable resistance over their life. They typically last longer than SiC elements, especially when operated consistently at the high temperatures for which they are designed.

Understanding the Trade-offs and Maintenance

The day-to-day realities of furnace operation, including maintenance and failure, present critical trade-offs that impact cost and uptime.

The Replacement Dilemma

MoSi2 elements are almost always wired in series and can be replaced individually when one fails. This simplifies maintenance and can lower the immediate cost of a single failure.

SiC elements are typically wired in parallel. Because their resistance changes with age, a new element will draw a different amount of power than the older ones. Therefore, they must be replaced in matched pairs or complete sets to ensure a balanced electrical load and uniform heating.

Contamination and Sensitivity

MoSi2 is highly susceptible to chemical attack and contamination. For example, in dental applications, coloring agents for zirconia can degrade the element's protective silica layer, leading to premature failure. This sensitivity demands excellent furnace hygiene and careful process control.

SiC is generally more resistant to chemical contamination, adding to its reputation as a robust and forgiving heating element.

Making the Right Choice for Your Application

Your decision should be a direct function of your process requirements, balancing performance needs with operational realities.

- If your primary focus is reaching maximum temperatures (above 1600°C): Choose MoSi2 for its unmatched stability in high-temperature, oxidizing environments.

- If your primary focus is versatility and rapid cycling: Choose SiC for its superior thermal shock resistance and reliable performance across various atmospheres.

- If your primary focus is simplified maintenance: MoSi2 offers the benefit of individual element replacement, which can be a significant advantage for uptime.

- If your furnace environment is not strictly controlled or contains potential contaminants: SiC is the safer, more robust choice due to its lower sensitivity to chemical attack.

By aligning the unique strengths of each element with your specific process goals, you ensure optimal performance, efficiency, and return on investment.

Summary Table:

| Feature | MoSi2 Heating Elements | SiC Heating Elements |

|---|---|---|

| Max Operating Temperature | Up to 1800°C | Up to 1600°C |

| Atmosphere Suitability | Oxidizing atmospheres only | Oxidizing, reducing, and variable atmospheres |

| Thermal Shock Resistance | Low | High |

| Mechanical Strength | Brittle at room temperature | Superior |

| Lifespan | Longer, stable resistance | Shorter, resistance increases with age |

| Replacement | Individual elements in series | Matched pairs or sets in parallel |

| Contamination Sensitivity | High | Low |

Struggling to select the right heating element for your lab's high-temperature furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your furnace performance and efficiency!

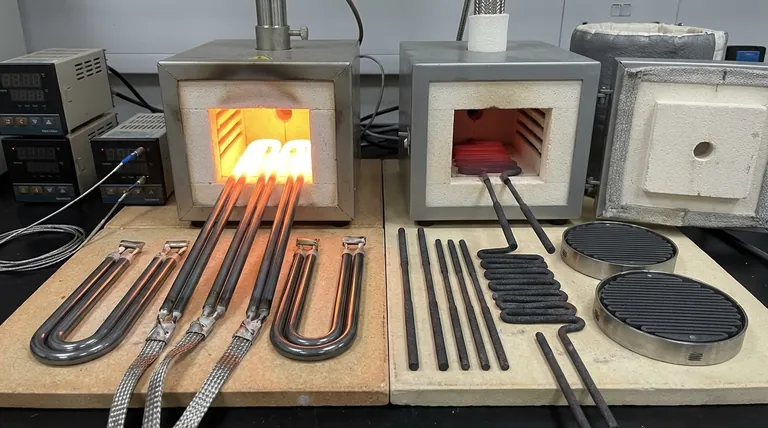

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C