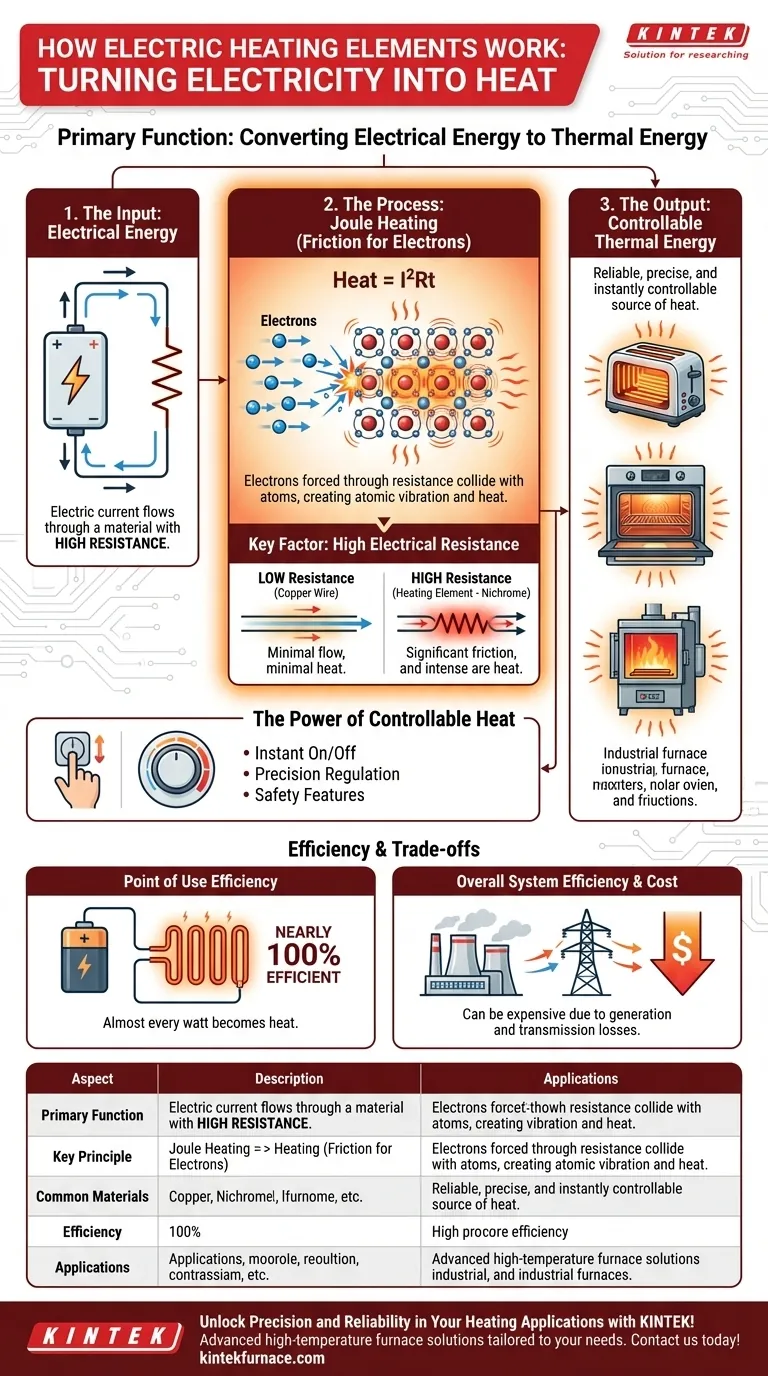

The primary function of an electric heating element is to convert electrical energy directly into thermal energy. This transformation is achieved by passing an electric current through a material with high electrical resistance. The resistance impedes the flow of electricity, causing the material to heat up in a process known as Joule heating.

At its core, an electric heating element is a specialized resistor designed for one purpose: to turn the flow of electricity into a reliable, controllable source of heat. This simple principle of energy conversion is the foundation for countless household and industrial applications.

How a Simple Wire Becomes a Source of Heat

The magic of electric heat isn't magic at all; it's a fundamental principle of physics. When electricity encounters opposition, it releases energy. Heating elements are engineered to maximize this effect.

The Principle of Joule Heating

Every electric heating element operates on the principle of Joule heating. Think of it like friction. As electrons (the electric current) are forced to move through a material that resists their flow, they collide with atoms, causing them to vibrate. This increased atomic vibration is what we perceive as heat.

The amount of heat generated is predictable. It is determined by the intensity of the current squared, the material's resistance, and the duration of the flow (Heat = I²Rt).

The Critical Role of Resistance

A material's suitability as a heating element is defined by its electrical resistance. While a copper wire is designed for low resistance to transmit power efficiently, a heating element is made from materials specifically chosen for their high resistance.

This high resistance is what forces the conversion of electrical energy into heat, rather than allowing it to pass through with minimal loss.

Materials Engineered for Heat

Heating elements are typically made from alloys like nichrome (nickel-chromium). These materials are ideal because they not only have high resistance but can also withstand very high temperatures without oxidizing, melting, or becoming brittle.

Why This Matters: The Power of Controllable Heat

The conversion of electricity to heat provides a level of control and convenience that is difficult to achieve with other heat sources like combustion.

From Fire to a Flick of a Switch

Electric elements offer the raw power of fire with the precision and simplicity of an electrical circuit. Heat can be switched on instantly, adjusted with a dial, and turned off completely, providing an unparalleled level of responsiveness.

Precision and Safety

Because the heat output is directly related to the electrical current, it can be regulated with extreme precision by thermostats and controllers. This allows appliances like ovens to maintain an exact temperature and enables safety features that can shut off power to prevent overheating.

Ubiquitous in Modern Life

This technology is so reliable and adaptable that it has become invisible. You can find heating elements in toasters, electric stoves, water heaters, clothes dryers, hair dryers, and sophisticated industrial process heaters.

Understanding the Trade-offs

While effective, electric resistive heating is not without its limitations. Objectivity requires acknowledging its place among other heating technologies.

Efficiency at Point of Use

The conversion of electrical energy into heat within a resistive element is nearly 100% efficient. Almost every watt of electricity consumed by the element becomes a watt of heat energy released into the immediate environment.

Overall System Efficiency and Cost

However, the "wall-to-heat" efficiency can be misleading. The electricity itself had to be generated at a power plant and transmitted over lines, both of which involve energy losses.

For this reason, direct resistive heating can be one of the more expensive forms of heating compared to alternatives like natural gas furnaces or high-efficiency electric heat pumps, which move heat rather than creating it.

Making the Right Choice for Your Goal

Understanding this principle allows you to see the technology around you with greater clarity and make informed decisions.

- If your primary focus is on understanding appliances: Recognize that the glowing wires in a toaster or space heater are simply a resistor doing its job—turning electrical flow into useful heat.

- If your primary focus is on choosing a heating system: Remember that while electric resistive heat is simple and efficient at the point of use, its operational cost is directly tied to your local price of electricity.

- If your primary focus is on the physics: The core concept is Joule heating, where a material's resistance to electron flow is harnessed to generate thermal energy on demand.

By mastering this fundamental energy conversion, you can appreciate how countless modern technologies provide clean and controllable heat.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Converts electrical energy into thermal energy via Joule heating |

| Key Principle | High electrical resistance causes heat generation (Heat = I²Rt) |

| Common Materials | Nichrome and other alloys for high resistance and temperature durability |

| Efficiency | Nearly 100% efficient at point of use |

| Applications | Household appliances (toasters, ovens) and industrial heaters |

Unlock Precision and Reliability in Your Heating Applications with KINTEK!

At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for superior performance and durability. With our strong deep customization capability, we precisely meet the unique experimental requirements of diverse laboratories, ensuring optimal efficiency and safety.

Ready to enhance your lab's heating processes? Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals