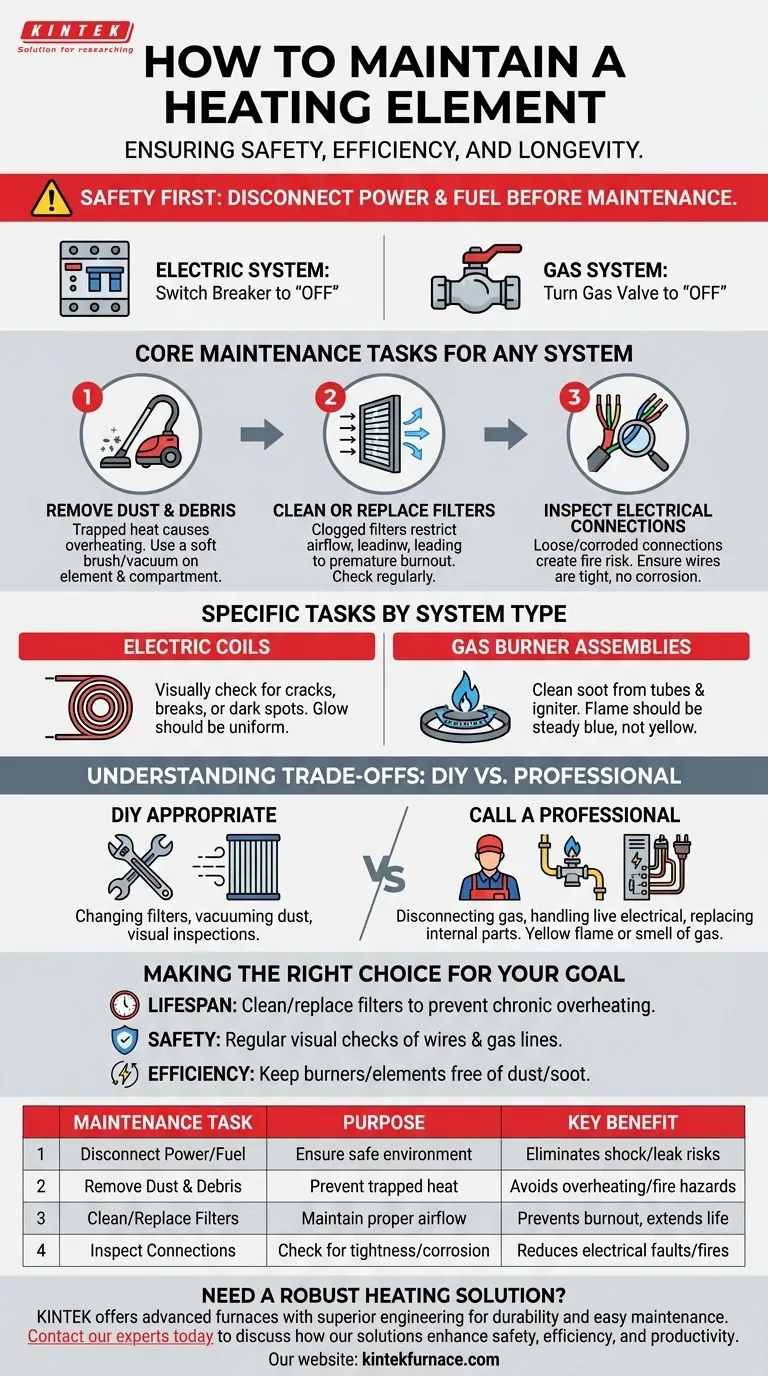

To properly maintain a heating element, you must first ensure all power or gas is disconnected from the unit. The core tasks involve removing dust and debris from the element and surrounding area, inspecting all electrical connections for tightness and corrosion, and ensuring system filters are clean to allow for proper airflow, which prevents overheating.

The goal of heating element maintenance is not just cleaning, but preventing the three primary causes of failure: overheating, corrosion, and electrical faults. A consistent, simple maintenance routine directly addresses these root causes, ensuring safety, efficiency, and a longer operational life.

The Foundation: Safety First

Before you touch any component, your first priority must be to create a safe working environment. Attempting maintenance on a live system is extremely dangerous.

### Disconnecting Power and Fuel

For an electric heating system (like an electric furnace, oven, or water heater), locate the dedicated circuit breaker in your electrical panel and switch it to the "OFF" position. This is the only guaranteed way to de-energize the element.

For a gas system (like a gas furnace or water heater), find the gas shut-off valve near the appliance and turn it to the "OFF" position. This is typically a handle that you turn 90 degrees until it is perpendicular to the pipe.

Core Maintenance Tasks for Any System

These fundamental steps apply to nearly all types of heating systems and form the basis of good maintenance. They focus on keeping the system clean and clear of obstructions.

### Remove Dust and Debris

Dust, lint, and other debris are insulators. When they coat a heating element, they trap heat, forcing the element to run hotter and longer to achieve the target temperature.

Use a vacuum with a brush attachment or a soft-bristled brush to gently clean the heating element itself and the compartment around it. This single step is critical for preventing overheating and potential fire hazards.

### Clean or Replace System Filters

A clogged air filter is one of the most common causes of heating system failure. It restricts airflow, which is necessary to carry heat away from the element.

Poor airflow forces the element to overheat, which can trip safety limit switches or, over time, cause the element to burn out prematurely. Check and replace your system's filters regularly according to the manufacturer's schedule.

### Inspect Electrical Connections

For electric elements, loose or corroded electrical connections create high resistance. This resistance generates intense, localized heat that can melt wire insulation, damage terminals, and create a significant fire risk.

Visually inspect all wires connected to the element. Ensure they are tightly secured and show no signs of corrosion, fraying, or discoloration from overheating.

Specific Tasks for Your System Type

While the principles are similar, the specific components you inspect will differ between electric and gas-powered systems.

### For Electric Coils

Electric heating elements are often simple coils of wire. After cleaning, visually inspect the coils for any cracks, breaks, or dark spots, which indicate an impending failure. A failing element may also glow bright orange in one spot while the rest of the coil is a duller red.

### For Gas Burner Assemblies

In a gas furnace, the "heating element" is the burner assembly. After shutting off the gas, use a vacuum and a stiff brush to clean any soot or debris from the burner tubes and igniter.

When the system is running, the flame should be a steady, consistent blue color. A yellow or flickering flame indicates incomplete combustion, which produces soot and carbon monoxide and requires professional service.

Understanding the Trade-offs: DIY vs. Professional Service

Knowing your limitations is as important as knowing the maintenance steps themselves. Certain tasks are safe for a homeowner, while others carry significant risks.

### When DIY is Appropriate

Simple, non-invasive tasks are generally safe for DIY maintenance. This includes changing air filters, vacuuming dust and debris from accessible areas, and performing visual inspections of the element and its connections (with the power off).

### When to Call a Professional

Any task that involves disconnecting gas lines, handling live electrical components, or replacing internal parts should be left to a qualified technician. If you notice a yellow gas flame, smell gas, or find damaged wiring, shut down the system immediately and call for professional service. Annual professional tune-ups are highly recommended.

Making the Right Choice for Your Goal

Your maintenance priorities can be tailored to your primary objective, whether it's maximizing lifespan, ensuring safety, or boosting efficiency.

- If your primary focus is extending appliance lifespan: Consistently clean or replace your system's air filters to prevent the chronic overheating that degrades components over time.

- If your primary focus is safety: Make regular visual inspections of electrical wires and gas lines the cornerstone of your routine.

- If your primary focus is peak efficiency: Keep burners and elements free of dust and soot to ensure optimal heat transfer and combustion.

Ultimately, simple and consistent maintenance is the most effective way to protect your investment and ensure your heating system operates reliably when you need it most.

Summary Table:

| Maintenance Task | Purpose | Key Benefit |

|---|---|---|

| Disconnect Power/Fuel | Ensure a safe working environment | Eliminates risk of electric shock or gas leaks |

| Remove Dust & Debris | Prevent heat from being trapped | Avoids overheating and potential fire hazards |

| Clean/Replace Filters | Maintain proper airflow | Prevents burnout and extends component life |

| Inspect Connections | Check for tightness and corrosion | Reduces risk of electrical faults and fires |

Need a robust heating solution designed for longevity and easy maintenance? At KINTEK, we understand that reliable performance starts with superior engineering. Our advanced high-temperature furnaces, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, are built with exceptional R&D and in-house manufacturing to ensure durability and simplify your maintenance routine. Leverage our deep customization capability to get a furnace that precisely meets your unique experimental requirements.

Contact our experts today to discuss how our heating solutions can enhance your lab's safety, efficiency, and productivity.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production