The key to preventing muffle furnace maintenance is not avoiding it entirely, but shifting from reactive repairs to proactive, preventative care. This involves a disciplined approach to the initial setup, daily operation, and routine inspections. By following a few core principles, you can significantly extend the lifespan of the furnace, ensure its operational reliability, and prevent the costly downtime associated with unexpected failures.

Preventing major maintenance issues is a matter of strategy, not luck. It begins with correctly preparing the furnace before its first use and is sustained by integrating safety and routine checks into your standard operating procedures.

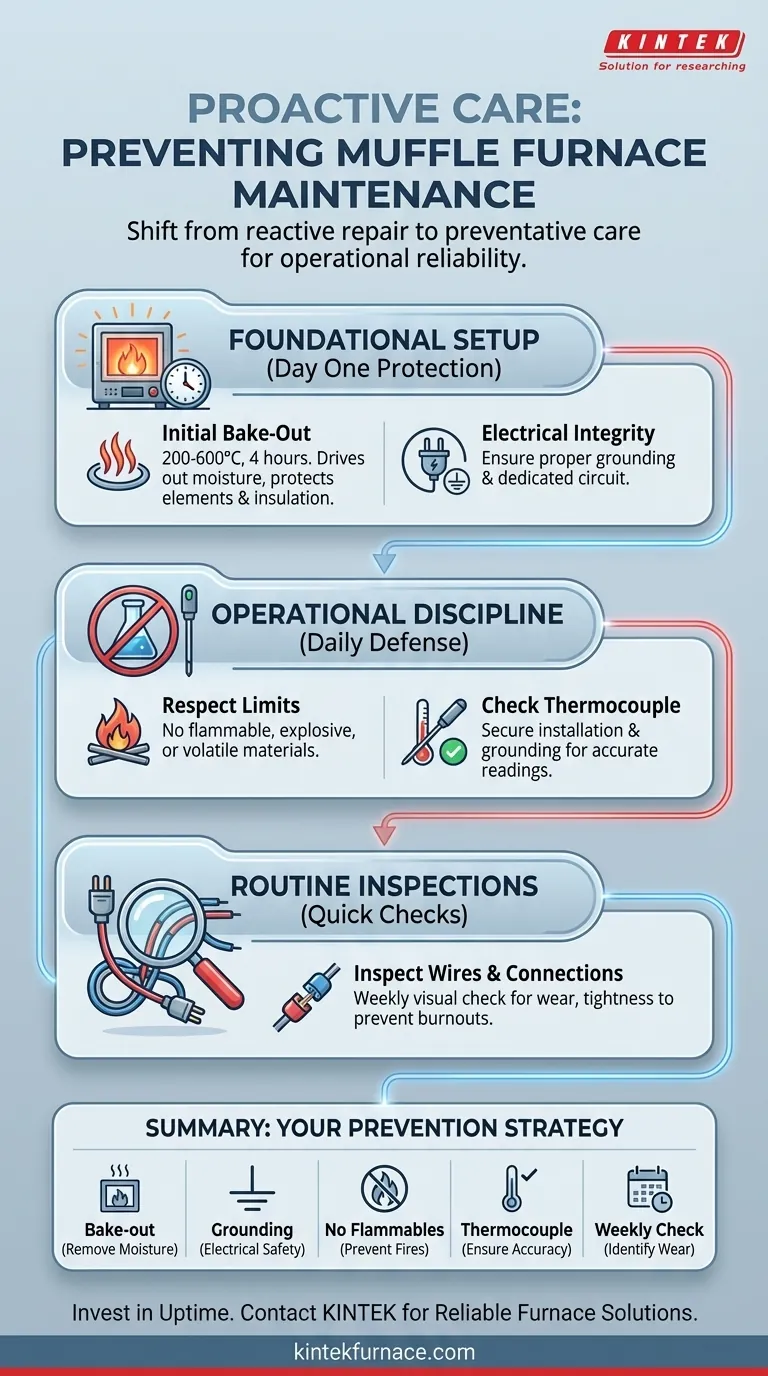

Foundational Setup: Preventing Problems from Day One

The most critical maintenance prevention occurs before you even run your first real sample. These initial steps are designed to protect the furnace's most vital components from damage.

The Importance of the Initial Bake-Out

Before its first use or after a long period of inactivity, you must bake the furnace. This process involves heating the chamber to between 200°C and 600°C and holding it for approximately four hours.

This procedure is not optional; it is essential for driving out any accumulated moisture from the refractory insulation. Firing a damp furnace can cause the moisture to turn to steam rapidly, which can crack the insulation or, more critically, damage the electric heating elements, leading to premature failure.

Ensuring Electrical Integrity

A stable and safe electrical supply is fundamental to the longevity of the furnace's control systems and heating elements.

Ensure the furnace is properly grounded. This is a non-negotiable safety measure to prevent electric shock and protect the sensitive electronic controller from electrical faults.

Use a dedicated electrical circuit and gate to control the main power. This prevents overloading the circuit, which can damage the furnace's power supply and electronics, and ensures a stable voltage for consistent heating performance.

Operational Discipline: Your First Line of Defense

How you use the furnace every day has a direct impact on its long-term health. Careless operation is a common cause of avoidable damage.

Respecting Material Limits

Never place flammable, explosive, or volatile materials inside the furnace. This is primarily a safety rule, but an internal fire or explosion will cause catastrophic damage to the chamber and heating elements, representing the most severe form of maintenance failure.

The Role of Accurate Temperature Measurement

The furnace's thermocouple is its nerve center, providing the temperature data that the controller uses to regulate the heating elements.

Regularly check that the thermocouple is securely installed and well-grounded. A loose or poorly grounded thermocouple can provide inaccurate readings, causing the furnace to overheat or underheat. Chronic overheating, even by a small margin, will drastically shorten the life of the heating elements.

The Core of Prevention: Routine Inspections

Simple, quick visual checks can alert you to developing problems before they become critical failures.

Inspecting Wires and Connections

Periodically perform a visual inspection of the wiring for both the furnace and the controller. Look for signs of wear, brittleness, or discoloration, which can indicate overheating or degradation.

A loose connection is a point of high resistance, which generates excess heat and can lead to a burnout or electrical fire. Ensuring all connections are tight is a simple but powerful preventative step.

Understanding the Trade-offs: Proactive Care vs. Reactive Repair

It is tempting to skip these preventative steps to save time. However, this approach trades a few minutes of proactive inspection for the risk of days of downtime and significant repair costs.

The cost of replacing heating elements or a damaged controller far exceeds the minimal effort required for a bake-out or a visual wire inspection. Investing in preventative care is an investment in operational uptime and reliability. Neglect guarantees that failures will occur at the most inconvenient times, disrupting projects and budgets.

A Proactive Maintenance Strategy

Your approach should be based on your usage patterns. A furnace used daily requires more frequent checks than one used weekly.

- If your furnace is new or has been inactive for months: Your absolute first step is to perform the full bake-out procedure to eliminate moisture.

- If you are a frequent or daily user: Prioritize weekly visual inspections of all wiring and ensure the thermocouple connection is secure and clean.

- If you suspect temperature inaccuracies: Immediately verify the thermocouple is properly grounded and seated before assuming a more significant controller or element failure.

By treating your muffle furnace as a precision instrument that requires consistent care, you transform it from a potential liability into a reliable, long-term asset.

Summary Table:

| Prevention Strategy | Key Action | Purpose |

|---|---|---|

| Initial Setup | Perform a bake-out (200-600°C for 4 hours) | Drive out moisture to prevent damage to insulation and heating elements. |

| Electrical Safety | Ensure proper grounding & use a dedicated circuit | Protect electronics and ensure stable, safe operation. |

| Daily Operation | Avoid flammable/volatile materials | Prevent internal fires/explosions that cause catastrophic damage. |

| Temperature Accuracy | Check thermocouple installation & grounding | Prevent inaccurate readings that lead to overheating and element failure. |

| Routine Inspection | Visually inspect wires & connections weekly | Identify wear, looseness, or overheating before they cause failure. |

Maximize the reliability and lifespan of your laboratory equipment.

At KINTEK, we understand that consistent performance is critical for your research and production. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements.

Ensure your furnace is a long-term asset, not a liability. Contact our experts today to discuss your specific needs and discover how our robust and reliable solutions can enhance your operational uptime.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation