For ultra-high-temperature applications, the primary materials used for heating elements are molybdenum disilicide (MoSi₂), silicon carbide (SiC), and refractory metals like tungsten (W). These materials are selected for their ability to operate reliably at temperatures far exceeding the limits of common nickel-chromium alloys, which are typically capped at around 1400°C.

The selection of an ultra-high-temperature heating element is not a simple matter of choosing the material with the highest melting point. The single most important factor is the operating atmosphere, as it dictates whether a material will perform reliably or fail catastrophically.

The Tiers of High-Temperature Materials

To understand ultra-high-temperature elements, it's helpful to first categorize materials by their operational capabilities and environments.

The Workhorses: Metallic Alloys (Up to ~1400°C)

The most common heating elements are made from nickel-chromium (NiCr) alloys, like Nichrome, or iron-chromium-aluminum (FeCrAl) alloys, like Kanthal.

These materials are prized for their ductility, relatively low cost, and excellent performance in air. Their high-temperature capability comes from the formation of a stable, protective oxide layer on their surface that prevents further oxidation.

The Air-Firing Champions: Ceramics (Up to 1900°C)

When temperatures need to exceed the limits of metallic alloys in an air-filled furnace, ceramic elements are the definitive choice.

Molybdenum Disilicide (MoSi₂) elements are a top choice for industrial furnaces operating up to 1850°C. At high temperatures, they form a protective layer of pure silica glass (SiO₂) that self-heals if damaged, providing exceptional resistance to oxidation.

Silicon Carbide (SiC) elements are robust, rigid, and chemically inert, making them suitable for aggressive environments up to 1600°C. They are often used where chemical resistance is as important as temperature.

The Vacuum Specialists: Refractory Metals (Up to 3000°C+)

For the most extreme temperatures, tungsten (W) and molybdenum (Mo) are the only viable options. Tungsten, with its melting point of 3422°C (6191°F), is the champion of high-temperature performance.

However, these materials have a critical weakness: they oxidize and disintegrate rapidly in the presence of oxygen at high temperatures. Therefore, they can only be used in a vacuum or a pure, inert atmosphere (like argon or nitrogen).

Understanding the Trade-offs: Atmosphere is Everything

Choosing the wrong material for your operating environment is the most common and costly mistake in high-temperature system design.

Oxidation Resistance: The Protective Layer

The success of NiCr, FeCrAl, and MoSi₂ elements in air is entirely due to their ability to form a passivation layer. This thin, self-regenerating layer of oxide (chromia, alumina, or silica) acts as a barrier, protecting the underlying material from burning away.

This is why these elements can operate for thousands of hours in an oxygen-rich environment without significant degradation.

The Oxidation Vulnerability of Refractory Metals

Tungsten and molybdenum do not form a stable, protective oxide layer. When heated in air, their oxides are volatile and simply sublime away, rapidly consuming the element.

Using a tungsten element in an air-firing furnace will result in immediate and catastrophic failure. Its high-temperature strength is only accessible when oxygen is completely eliminated from the environment.

Mechanical Properties and Brittleness

There is also a trade-off between temperature performance and mechanical durability.

Metallic alloys like NiCr and FeCrAl are ductile and can be easily formed into coils. Ceramic elements like MoSi₂ and SiC are significantly more brittle and must be handled with care to prevent fracture from mechanical or thermal shock.

Making the Right Choice for Your Application

Your final decision must be guided by the specific demands of your process.

- If your primary focus is general-purpose heating in air up to 1300°C: FeCrAl or NiCr alloys offer the best combination of performance, durability, and cost-effectiveness.

- If your primary focus is industrial processing in air from 1300°C to 1850°C: Molybdenum disilicide (MoSi₂) is the industry standard for reliable, high-temperature air firing.

- If your primary focus is achieving extreme temperatures (>1800°C) in a controlled environment: Tungsten or molybdenum elements are essential, but they absolutely require a vacuum or inert gas atmosphere.

Ultimately, matching the material's properties to its precise operational environment is the key to a successful high-temperature system.

Summary Table:

| Material | Max Temperature (°C) | Key Atmosphere | Key Characteristics |

|---|---|---|---|

| NiCr/FeCrAl Alloys | ~1400 | Air | Ductile, cost-effective, forms protective oxide |

| Molybdenum Disilicide (MoSi₂) | 1850 | Air | Self-healing silica layer, oxidation-resistant |

| Silicon Carbide (SiC) | 1600 | Air/Aggressive | Rigid, chemically inert, robust |

| Tungsten (W) | 3000+ | Vacuum/Inert | Highest temperature, oxidizes in air |

| Molybdenum (Mo) | High (similar to W) | Vacuum/Inert | High-temperature strength, oxidizes in air |

Struggling to choose the right ultra-high-temperature heating element for your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your experimental requirements, enhancing efficiency and reliability. Don't let material selection hold you back—contact us today to discuss how our tailored high-temperature furnace solutions can benefit your laboratory!

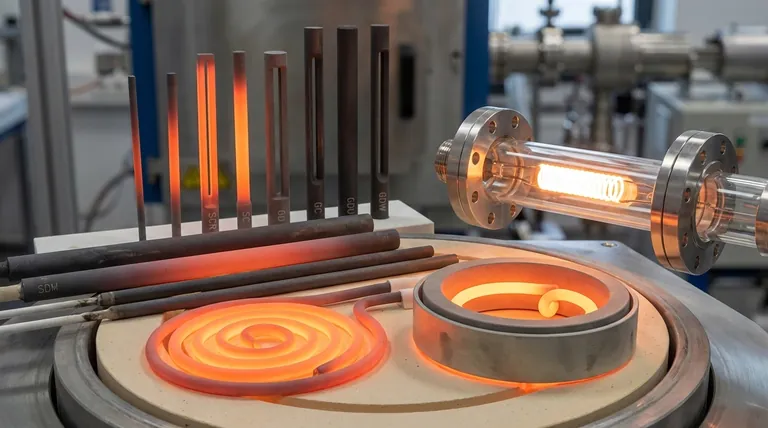

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer