In industrial heating, few parameters are as critical as watt-density. It is the measure of heat concentration on a heater's surface, calculated by dividing the total wattage by the heated surface area (watts per square inch). This single value dictates the intensity of heat transfer. Choosing the correct watt-density is the most important factor in ensuring a heating element operates efficiently, avoids damaging the substance being heated, and achieves a long, reliable service life.

Selecting a heater is not just about its total power output. The core challenge is matching the heater's concentration of heat (watt-density) to the specific material's ability to absorb it. A mismatch is the single most common cause of premature heater failure and process inefficiency.

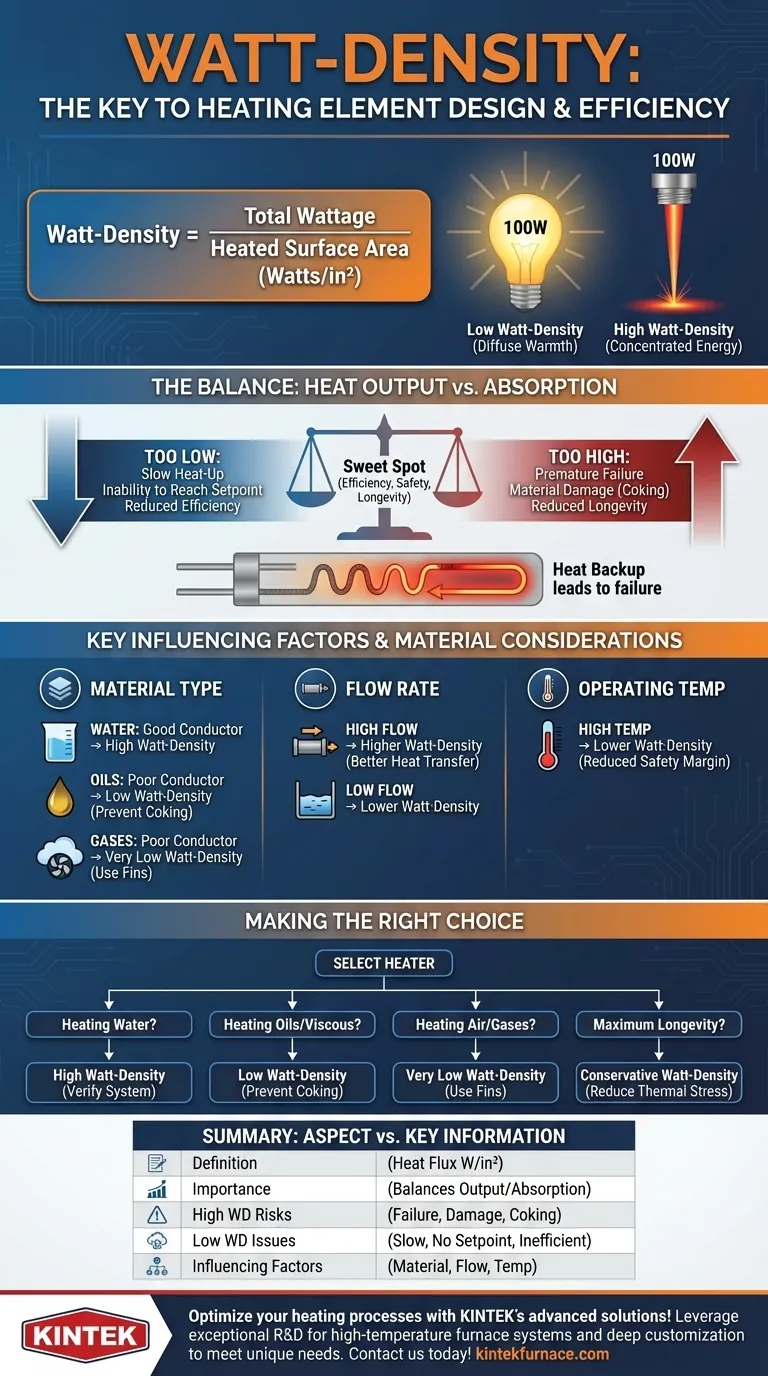

The Core Principle: Balancing Heat Output and Absorption

Watt-density is the bridge between the energy a heater produces and the capacity of the surrounding environment to accept that energy. Understanding this balance is fundamental to designing any effective thermal system.

What is Watt-Density?

Watt-density is a measure of heat flux. Think of it as the difference between a 100-watt light bulb and a 100-watt laser. Both have the same total power, but the laser's extremely high watt-density concentrates that energy into a tiny point with destructive potential, while the bulb's low watt-density spreads it out to provide gentle, diffuse warmth.

In heating elements, this value represents the rate of heat exchange from the element's sheath to the target material.

Why This Balance is Critical

A heating element's internal resistance wire generates a tremendous amount of heat. This heat must be conducted through the sheath material and transferred efficiently into the surrounding substance (the "load").

If the load cannot absorb heat as fast as the element produces it, the heat "backs up." This causes the internal temperature of the element to rise dramatically, far exceeding its design limits, leading directly to failure.

The Consequences of an Incorrect Watt-Density

Choosing the wrong watt-density has immediate and significant consequences for both the heater and the process it serves. The goal is to operate in the "sweet spot"—high enough for efficiency but low enough for safety and longevity.

The Dangers of Watt-Density Being Too High

This is the most common and costly mistake in heater specification.

-

Premature Heater Failure: When heat cannot escape quickly enough, the internal resistance wire can rapidly oxidize and break. The outer sheath material can also be compromised, leading to a complete burnout.

-

Damage to the Heated Material: For liquids, excessive watt-density can cause localized boiling or "coking"—the formation of a hard, carbonized layer on the heater's surface. This layer acts as an insulator, which ironically accelerates the heater's internal temperature rise and subsequent failure. For solids, it causes scorching or melting.

The Inefficiency of Watt-Density Being Too Low

While seemingly a "safer" option, an overly conservative (low) watt-density introduces its own set of problems.

-

Slow Heat-Up Times: The process will take significantly longer to reach its target temperature, which can reduce production throughput and efficiency.

-

Inability to Reach Setpoint: In systems with significant ambient heat loss, a heater with too low a watt-density may struggle or fail to reach the desired operating temperature.

Understanding the Trade-offs: What Determines a Safe Watt-Density?

The maximum allowable watt-density is not a fixed number; it is entirely dependent on the application. Several factors must be considered to make an informed decision.

The Material Being Heated

Different substances transfer heat at vastly different rates. This is the primary consideration.

- Water is an excellent heat conductor and can accept a high rate of thermal energy, allowing for high watt-densities.

- Oils and viscous fluids have poor thermal conductivity. They require much lower watt-densities to prevent chemical breakdown (coking) at the sheath surface.

- Gases (like air) are extremely poor heat conductors. They require very low watt-densities, often paired with fins to increase the surface area for heat transfer.

Operating Conditions

The physical conditions of the process play a crucial role.

- Flow Rate: For flowing liquids or air, a higher velocity across the heater surface carries heat away more effectively, permitting a higher watt-density. A static or slow-moving fluid requires a lower watt-density.

- Operating Temperature: As the target temperature increases, the safety margin decreases. A lower watt-density should be used for high-temperature applications to prevent overshoot and material degradation.

Making the Right Choice for Your Goal

To select the correct heater, you must match the watt-density to the specific demands of your process. Always consult manufacturer charts for specific recommendations, but use these principles as your guide.

- If your primary focus is heating water or non-corrosive aqueous solutions: You can often use a higher watt-density for rapid heating, but always verify based on system pressure and flow.

- If your primary focus is heating oils, glucose, or other viscous liquids: You must select a low watt-density to prevent coking, which would foul the heater and contaminate your product.

- If your primary focus is heating air or other gases: You must use a very low watt-density element, often with fins, to compensate for the poor heat transfer characteristics of gases.

- If your primary focus is maximum heater longevity: Choose a conservative watt-density for your application. This reduces thermal stress on the element and provides a buffer against unexpected process variations.

Ultimately, treating watt-density as the key design parameter, not just total power, is the foundation of a reliable and efficient thermal system.

Summary Table:

| Aspect | Key Information |

|---|---|

| Definition | Watt-density is heat flux measured in watts per square inch, indicating heat concentration on a heater's surface. |

| Importance | Balances heat output with material absorption to prevent failures, ensure efficiency, and extend service life. |

| High Watt-Density Risks | Can cause premature heater failure, material damage like coking or scorching, and reduced longevity. |

| Low Watt-Density Issues | Leads to slow heat-up times, inability to reach setpoint temperatures, and decreased process efficiency. |

| Factors Influencing Choice | Depends on material type (e.g., water, oils, gases), flow rate, and operating temperature for safe application. |

Optimize your heating processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your specific requirements and deliver superior performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation