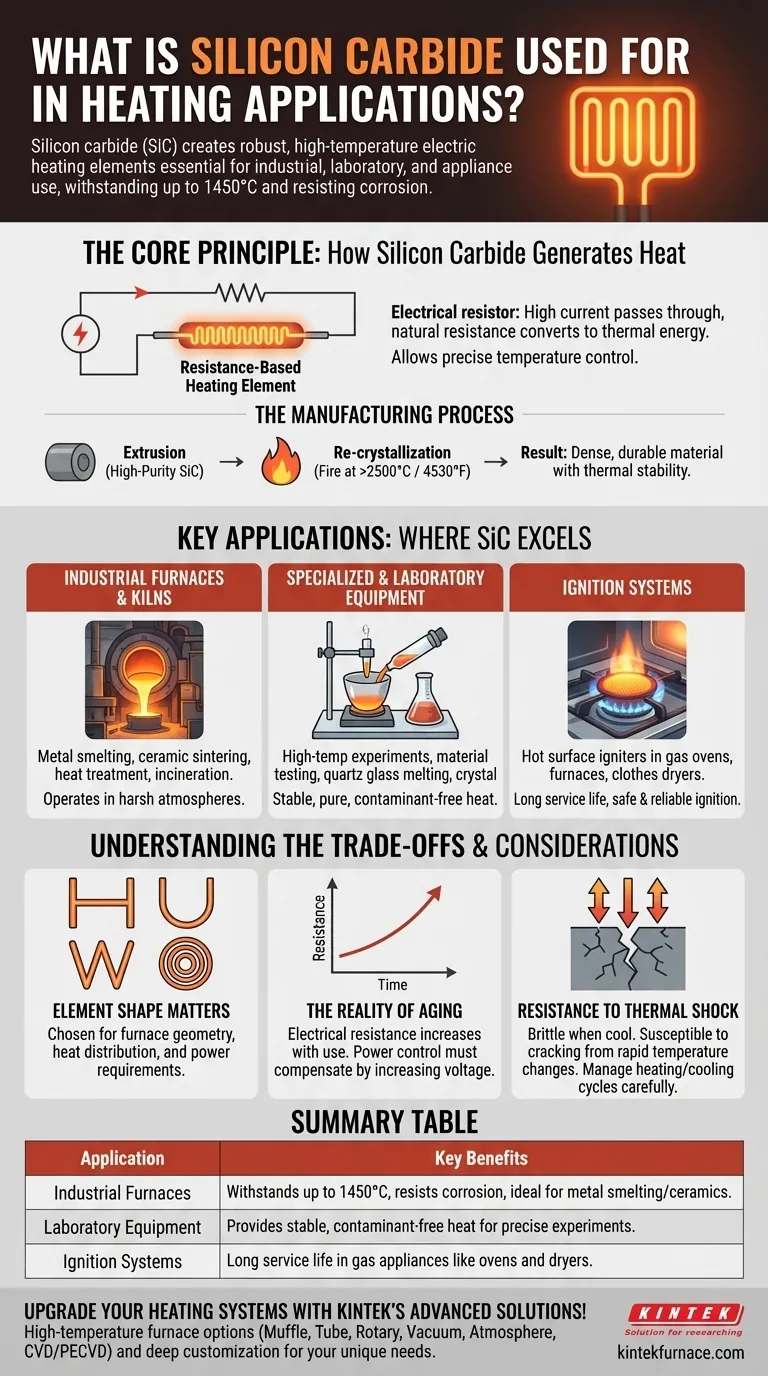

In heating applications, silicon carbide is primarily used to create robust, high-temperature electric heating elements. These elements are essential components in a wide range of equipment, from industrial furnaces used for melting metal and firing ceramics to the small hot surface igniters that light the gas in your home oven or clothes dryer.

Silicon carbide's value stems from its unique ability to withstand extreme temperatures (up to 1450°C), resist chemical corrosion, and provide a long service life. This combination makes it the material of choice for generating intense, controllable heat in harsh environments where other materials would quickly degrade or fail.

The Core Principle: How Silicon Carbide Generates Heat

A Resistance-Based Heating Element

At its core, a silicon carbide heating element is a type of electrical resistor. When a strong electric current is passed through it, the material's natural resistance causes it to heat up, converting electrical energy into thermal energy.

This process allows for highly precise temperature control by simply adjusting the voltage or current supplied to the element.

The Manufacturing Process

These elements are made from high-purity silicon carbide that is extruded into specific shapes, such as rods or tubes.

They are then fired in a process called re-crystallization at temperatures exceeding 2500°C (4530°F). This creates an extremely dense and durable material with strong, uniform bonds, giving the final product its signature strength and thermal stability.

Key Applications: Where SiC Excels

Industrial Furnaces and Kilns

This is the most common application for silicon carbide heating elements. They provide the high temperatures needed for processes like metal smelting, ceramic sintering, heat treatment of steel, and industrial incineration.

Their ability to operate in harsh atmospheres makes them ideal for these demanding industrial settings.

Specialized and Laboratory Equipment

In laboratory and R&D environments, SiC heaters are used in high-temperature experiments, material testing furnaces, and specialized equipment for quartz glass melting or high-temperature crystal growth.

Their stability ensures that experiments are repeatable and the heat source remains pure, without contaminating the samples.

Ignition Systems

On a smaller scale, hot surface igniters made from silicon carbide are a common component in modern gas-powered appliances.

Found in gas ovens, furnaces, and clothes dryers, these igniters heat up to a glow to safely and reliably ignite the flammable gas, offering a much longer service life than older pilot light systems.

Understanding the Trade-offs and Considerations

Why Element Shape Matters

Silicon carbide elements are manufactured in a variety of shapes—including straight rods (ED), U-shapes, W-shapes, and spirals (SG/SGR)—for a reason.

The shape is chosen to fit the specific geometry of a furnace, distribute heat evenly, and meet the electrical power requirements of the system. A straight rod is simple, while a U or W shape packs more heating power into a smaller space.

The Reality of Aging

While SiC elements have a very long service life, they do "age." Over hundreds or thousands of hours of use at high temperatures, their electrical resistance gradually increases.

This is a critical design consideration. The power control system must be able to increase the voltage over time to compensate for this rising resistance and maintain a constant power output and temperature. Failure to account for this is a common pitfall in furnace design.

Resistance to Thermal Shock

Silicon carbide is incredibly strong at high temperatures but can be brittle when cool. It is more susceptible to thermal shock (cracking from rapid temperature changes) than metallic heating elements.

Therefore, heating and cooling cycles must be managed carefully to maximize the element's lifespan.

Making the Right Choice for Your Application

Choosing silicon carbide is a decision based on the need for high heat in demanding conditions.

- If your primary focus is extreme industrial processes: SiC is the definitive choice for its unmatched temperature ceiling and durability in harsh chemical atmospheres.

- If your primary focus is precise laboratory heating: SiC provides the stable, clean, and controllable heat source required for sensitive and repeatable experiments.

- If your primary focus is reliable appliance ignition: A compact SiC igniter offers superior longevity and energy efficiency compared to older ignition technologies.

Ultimately, silicon carbide provides a robust and reliable solution for generating intense, controlled heat where conventional materials simply cannot survive.

Summary Table:

| Application | Key Benefits |

|---|---|

| Industrial Furnaces | Withstands up to 1450°C, resists corrosion, ideal for metal smelting and ceramics |

| Laboratory Equipment | Provides stable, contaminant-free heat for precise experiments |

| Ignition Systems | Long service life in gas appliances like ovens and dryers |

Upgrade your heating systems with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our silicon carbide heating elements can enhance your efficiency and reliability!

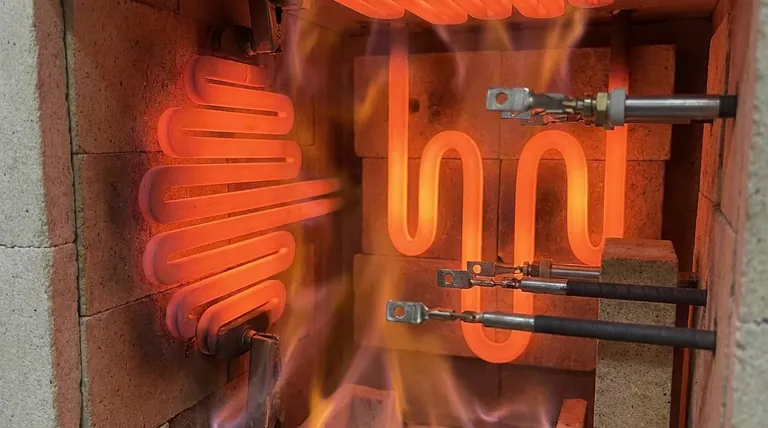

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan