In short, Silicon Carbide (SiC) heating elements are being integrated into premium residential products where performance is a key selling point. You will find them in high-efficiency electric space heaters, advanced kitchen appliances like toasters and ovens, and modern underfloor heating systems. Their adoption is driven by their ability to provide rapid, uniform heat and exceptional durability.

The core reason SiC technology is moving from industrial furnaces to home appliances is its ability to deliver superior performance. It allows for products that heat up significantly faster, distribute heat more evenly, and last longer than those using traditional heating elements.

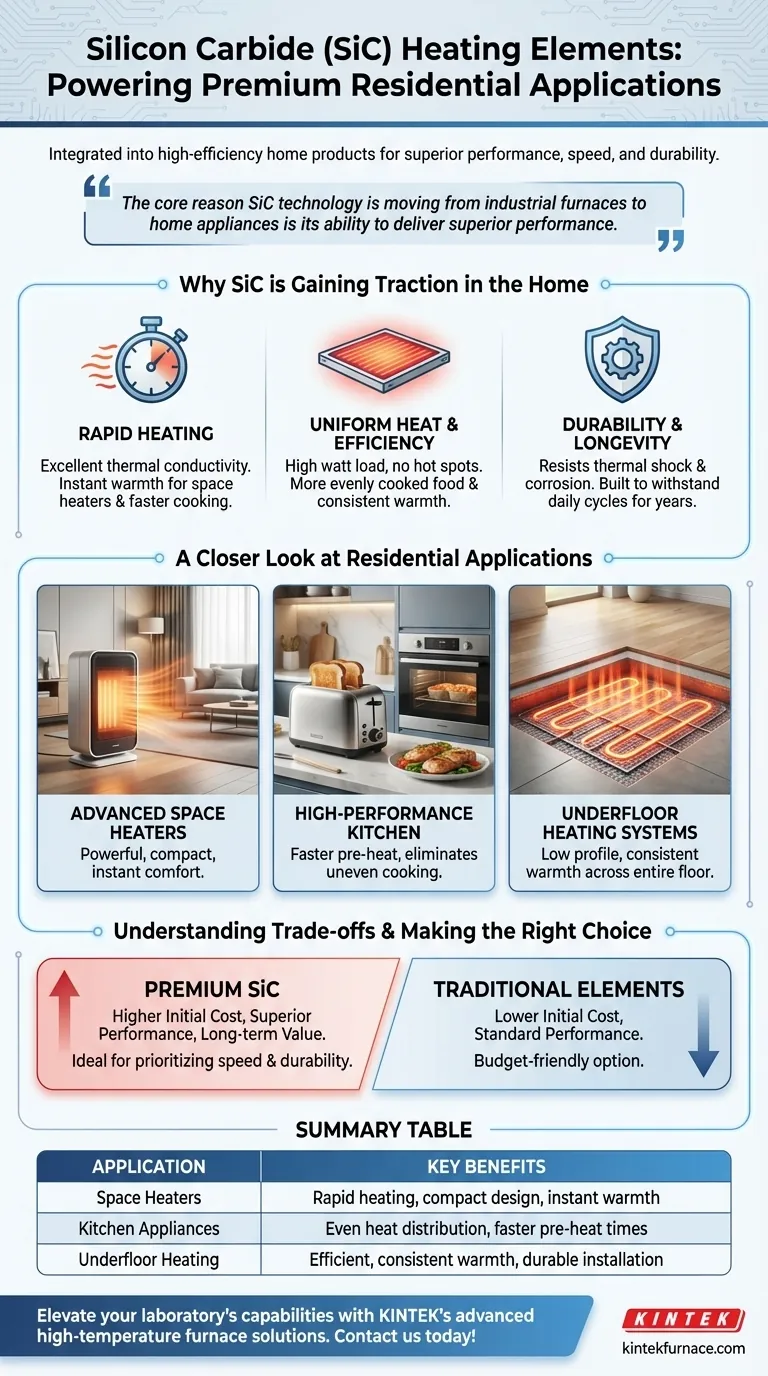

Why SiC is Gaining Traction in the Home

The use of SiC in residential applications is a direct result of bringing its industrial-grade advantages into a consumer context. The benefits center on speed, efficiency, and robustness.

The Principle of Rapid Heating

Silicon Carbide has excellent thermal conductivity. This means it transfers heat energy very quickly and efficiently.

For a residential product, this translates to a tangible user benefit: a space heater that warms a room faster or a toaster that provides even browning in less time.

Uniform Heat and Energy Efficiency

SiC elements can handle a high watt load, allowing for more compact and powerful designs. Their structure ensures highly uniform heat distribution.

This prevents hot spots, leading to more evenly cooked food in an oven or consistent warmth from a heater. This efficiency in heat transfer also contributes to better overall energy usage.

Durability and Longevity

These elements are highly resistant to thermal shock—the stress of rapid heating and cooling. They also resist chemical corrosion.

In practice, this means an appliance with an SiC heater is built to withstand the daily cycle of being turned on and off for years, leading to a longer product lifespan.

A Closer Look at Residential Applications

While traditionally found in high-temperature industrial settings like semiconductor and ceramics manufacturing, SiC is being selectively applied in the home where its unique properties offer a clear upgrade.

Advanced Space Heaters

The fast heating and compact nature of SiC allow for the creation of powerful yet smaller electric heaters. These units can begin emitting significant warmth almost instantly, improving comfort and efficiency.

High-Performance Kitchen Appliances

In toasters and ovens, the rapid and uniform heating of SiC is a major advantage. It allows for faster pre-heat times and eliminates the uneven cooking that can plague lower-end appliances.

Underfloor Heating Systems

SiC's ability to be formed into compact, durable elements makes it well-suited for underfloor heating. The system can be installed with a low profile while providing efficient, consistent warmth across the entire floor surface.

Understanding the Trade-offs

No technology is a universal solution. The decision to use SiC in a residential product involves balancing its advantages against practical considerations.

Cost vs. Performance

SiC heating elements are more advanced and typically more expensive to produce than traditional heating elements like nichrome wire.

As a result, you will primarily find SiC technology in premium or high-end appliances where consumers are willing to pay more for superior performance and durability. It is an ideal choice when cost is a factor, but performance cannot be compromised.

Industrial vs. Residential Demands

SiC elements can operate at extremely high temperatures (up to 1600°C), a capability essential for melting metal or firing ceramics.

This extreme temperature resistance is overkill for residential use. The real benefit for home products is not the maximum temperature but the speed and efficiency it delivers at much lower, safer temperatures.

Making the Right Choice for Your Goal

When evaluating an appliance, understanding the heating technology helps you align your purchase with your priorities.

- If your primary focus is performance and speed: Products with SiC heating elements are an excellent choice for their rapid heating and even heat distribution.

- If your primary focus is minimizing initial cost: Appliances using traditional heating elements will almost always be the more budget-friendly option.

- If your primary focus is long-term value: The enhanced durability and efficiency of SiC can justify a higher upfront investment through a longer product life and better performance.

Ultimately, choosing a product with a Silicon Carbide heater is a decision to prioritize industrial-grade performance and durability in your home.

Summary Table:

| Application | Key Benefits |

|---|---|

| Space Heaters | Rapid heating, compact design, instant warmth |

| Kitchen Appliances | Even heat distribution, faster pre-heat times |

| Underfloor Heating | Efficient, consistent warmth, durable installation |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our reliable and efficient heating technologies can drive your research forward!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance