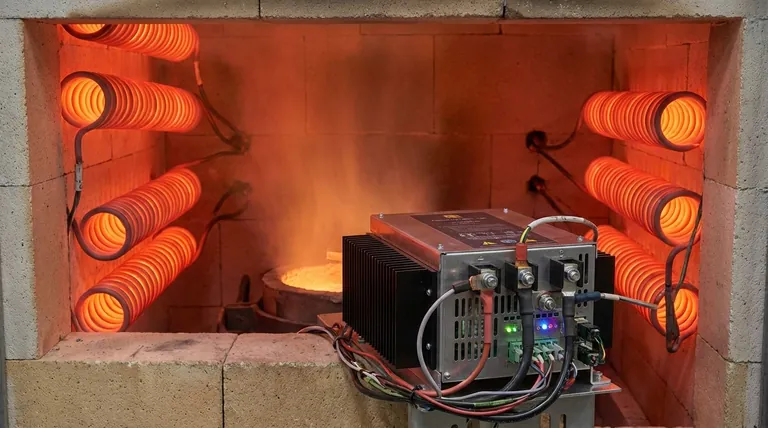

Heating coils in high-temperature furnaces are raw energy sources that require intelligent management to function correctly. Power regulators serve as the critical interface, dynamically adjusting the electrical output to the coils to match the specific thermal requirements of your metal processing application.

While the furnace controller acts as the brain, the power regulator acts as the muscle, translating low-voltage control signals into high-power adjustments. This modulation is the only way to transform raw electricity into precise, stable heat profiles without damaging temperature fluctuations.

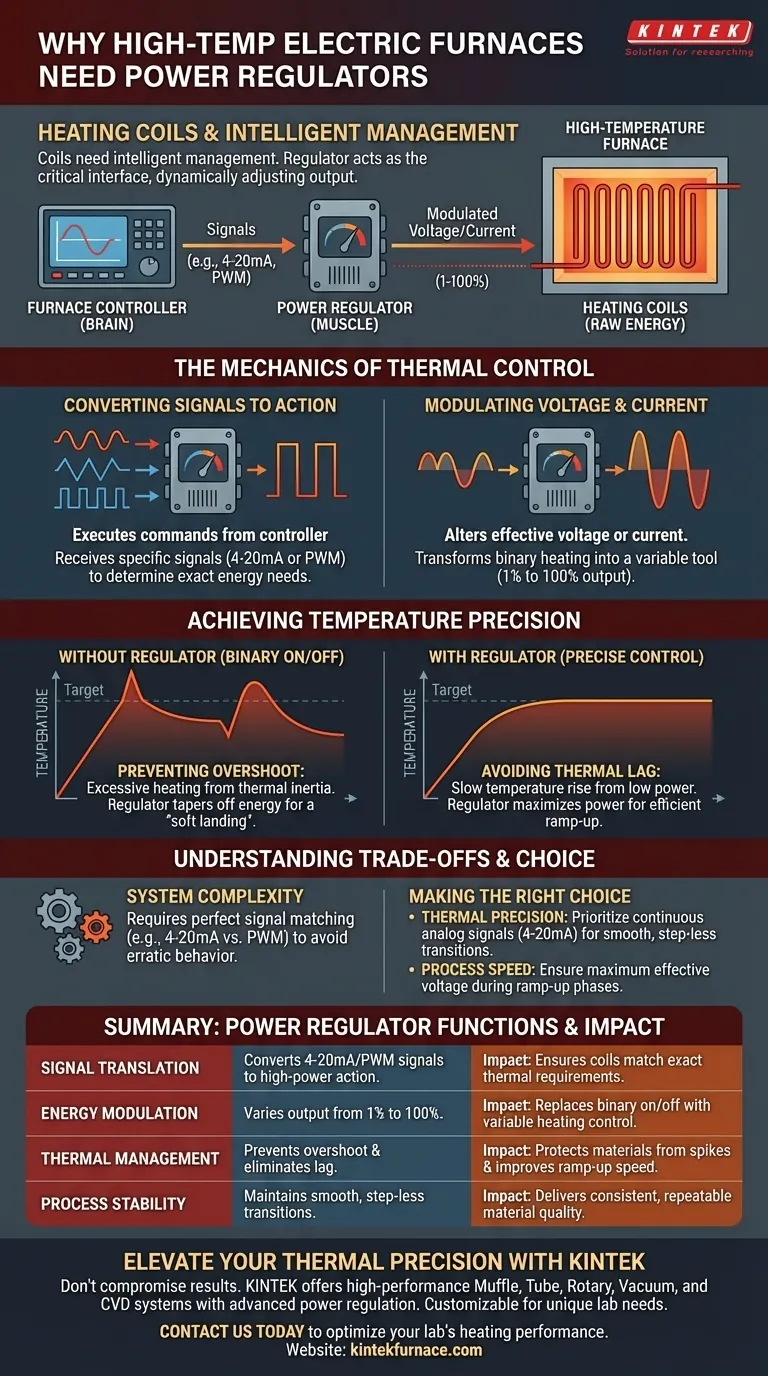

The Mechanics of Thermal Control

Converting Signals to Action

Power regulators do not make decisions; they execute commands based on input from the furnace controller. They receive specific control signals, typically 4-20mA or Pulse Width Modulation (PWM).

These signals tell the regulator exactly how much energy the system requires at any specific moment to maintain the desired process state.

Modulating Voltage and Current

Upon receiving the control signal, the regulator alters the effective voltage or current delivered to the heating coils.

This capability transforms the heating element from a binary device (simply on or off) into a variable tool. It allows the furnace to supply anywhere from 1% to 100% of its potential output based on immediate needs.

Achieving Temperature Precision

Preventing Temperature Overshoot

A major risk in metal processing is excessive heating, often caused by thermal inertia when coils run at full power for too long.

Power regulators mitigate this by tapering off the energy input as the furnace approaches its setpoint. This "soft landing" prevents the temperature from spiking beyond the target range.

Avoiding Thermal Lag

Conversely, if the power delivery is too low or static, the system suffers from a slow temperature rise.

Regulators dynamically maximize power delivery during the initial ramp-up phases. This ensures the furnace reaches operating temperature efficiently without the delays associated with insufficient power.

Understanding the Trade-offs

System Complexity and Compatibility

While power regulators are essential for precision, they introduce a layer of complexity to the furnace design.

The regulator must be perfectly matched to the controller's signal type (e.g., 4-20mA vs. PWM) to function correctly. A mismatch in signal interpretation can lead to erratic heating behavior, defeating the purpose of the device.

Making the Right Choice for Your Goal

To optimize your furnace's performance, select a regulation strategy that aligns with your specific processing needs:

- If your primary focus is Thermal Precision: Prioritize regulators that support continuous analog signals (like 4-20mA) to ensure smooth, step-less power transitions.

- If your primary focus is Process Speed: Ensure your regulator is calibrated to deliver maximum effective voltage during ramp-up phases to eliminate slow temperature rise.

The correct power regulator turns a simple heating element into a precision instrument capable of complex thermal profiles.

Summary Table:

| Feature | Function of Power Regulator | Impact on Metal Processing |

|---|---|---|

| Signal Translation | Converts 4-20mA/PWM signals to high-power action | Ensures coils match exact thermal requirements |

| Energy Modulation | Varies output from 1% to 100% | Replaces binary on/off with variable heating control |

| Thermal Management | Prevents overshoot and eliminates thermal lag | Protects materials from spikes and improves ramp-up speed |

| Process Stability | Maintains smooth, step-less power transitions | Delivers consistent, repeatable material quality |

Elevate Your Thermal Precision with KINTEK

Don't let inefficient energy management compromise your metal processing results. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable with advanced power regulation to meet your unique laboratory needs.

Our precision-engineered high-temp furnaces ensure stable heat profiles, preventing temperature overshoot and reducing thermal lag for superior efficiency. Contact us today to discover how KINTEK can optimize your lab's heating performance.

Visual Guide

References

- Serdar Ekinci, Євген Зайцев. Efficient control strategy for electric furnace temperature regulation using quadratic interpolation optimization. DOI: 10.1038/s41598-024-84085-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why Use Three Independent Heating Elements in Oxidation Kinetics? Achieve Precise Zonal Control for Accurate Data

- What properties make graphite heating elements easy to machine? Design Freedom for High-Temp Performance

- What is the primary purpose of thermal insulation cotton in annealing? Master Gradient Heat Control in Silicon Steel

- What type of heating elements are used in furnaces designed for 1200°C or less? Discover Efficient Solutions for Your Lab

- What is the significance of the temperature coefficient of resistance for a heating element? Choose the Right Element for Your Application

- Why is temperature uniformity important in processes like sintering, and how do high temperature heating elements help? Ensure Consistent Quality and Performance

- What material is used for the crucible in the resistive heating evaporation process? Alumina for Purity & Performance

- How can heating elements be supported within a furnace? Ensure Optimal Performance and Longevity