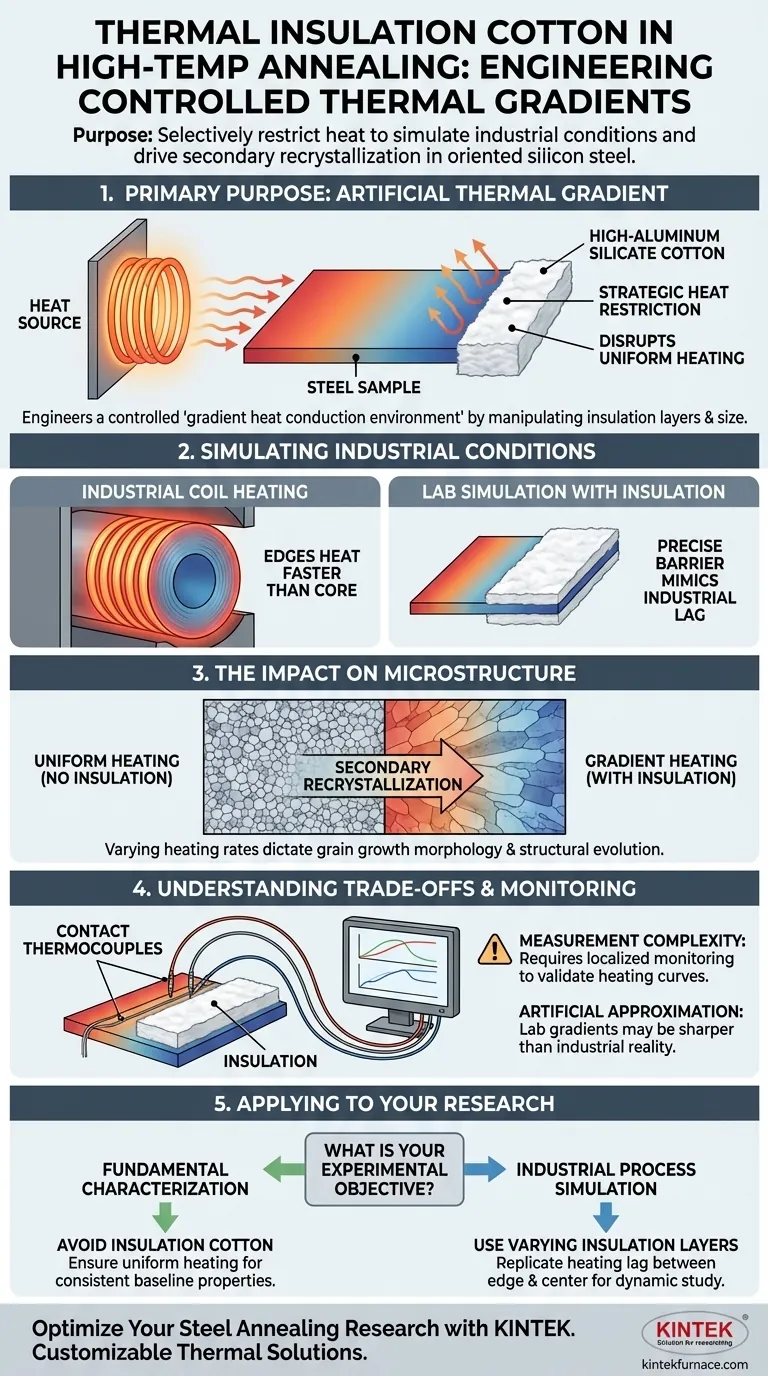

The primary purpose is to artificially engineer a controlled thermal gradient. By strategically covering specific areas of the oriented silicon steel sample with high-aluminum silicate thermal insulation cotton, researchers can selectively restrict the entry of heat energy. This process disrupts uniform heating, effectively simulating the uneven temperature distribution experienced by steel coils during industrial production.

By manipulating the number of layers and the size of the insulation cotton, researchers can create a "gradient heat conduction environment." This allows them to move beyond simple temperature tests and study exactly how varying heating rates across a single sample influence the material's structural evolution.

Simulating Industrial Conditions

Replicating Coil Heating

In large-scale industrial annealing, steel coils rarely heat uniformly. The outer edges often absorb heat much faster than the inner core.

The Role of Insulation

Thermal insulation cotton mimics this industrial reality in a small-scale laboratory setting. It acts as a barrier, slowing down heat transfer to specific sections of the sample.

Controlled Directionality

This is not random insulation; it is precise. Researchers can block heat from specific directions or edges to model exact production scenarios.

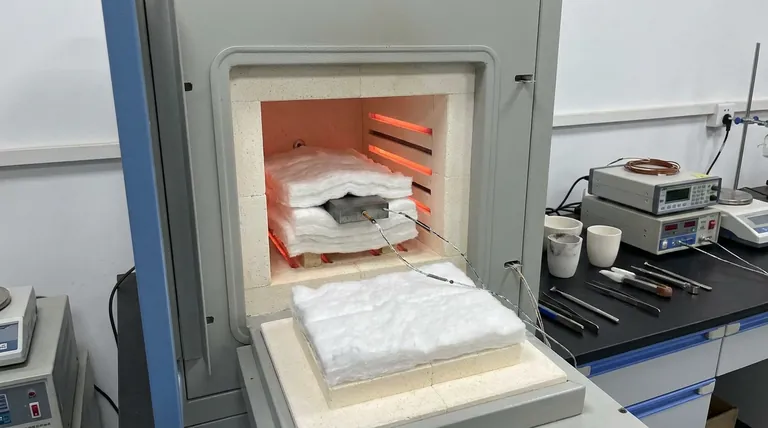

The Impact on Microstructure

Driving Secondary Recrystallization

The core phenomenon being studied here is secondary recrystallization. This is the process where certain crystalline grains grow significantly larger than their neighbors.

Linking Heat to Grain Growth

The heating gradient created by the cotton directly influences this growth. Differences in temperature rise rates across the sample lead to variations in grain growth morphology.

Quantifying the Difference

By comparing insulated areas against exposed areas, researchers can establish a correlation. They map how specific heating rate gradients result in specific grain structures.

Understanding the Trade-offs

Measurement Complexity

Introducing thermal gradients adds variables that must be rigorously monitored. Simple furnace temperature readings are no longer sufficient.

Requirement for Localized Monitoring

To validate the experiment, contact thermocouples must be placed at both the edges (fast heating) and centers (slowed heating) of the sample. Without real-time verification of the local heating curves, the data derived from the insulation cotton is unreliable.

Artificial vs. Natural

While this method simulates industrial conditions, it is still an artificial approximation. The boundary between the insulated and non-insulated zones in the lab may be sharper than the gradual gradients found in massive steel coils.

Applying This to Your Research

If you are designing an annealing experiment, the decision to use insulation cotton depends on your specific objective:

- If your primary focus is fundamental material characterization: Avoid insulation cotton to ensure uniform heating and consistent baseline properties across the sample.

- If your primary focus is industrial process simulation: Use varying layers of thermal insulation to replicate the heating lag between the coil edge and center.

The use of thermal insulation cotton transforms a standard annealing test into a dynamic study of how heat flow dictates the final crystalline structure of the steel.

Summary Table:

| Feature | Purpose in Annealing | Effect on Research |

|---|---|---|

| Material | High-aluminum silicate cotton | Strategic heat energy restriction |

| Simulation | Industrial coil heating lag | Replicates edge vs. core temperature variance |

| Mechanism | Gradient heat conduction | Drives selective secondary recrystallization |

| Monitoring | Contact thermocouples | Validates localized heating rate curves |

| Outcome | Microstructure mapping | Correlates grain growth with heating rates |

Optimize Your Steel Annealing Research with KINTEK

Precision in material science starts with the right equipment. Whether you are conducting fundamental material characterization or complex industrial process simulations, KINTEK provides the high-performance thermal solutions you need.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to accommodate your specific thermal insulation and gradient monitoring setups.

Unlock superior grain growth control today. Contact our experts to discuss your custom furnace requirements!

Visual Guide

References

- Qian Gao, Bo Li. Effect of Gradient Heat Conduction on Secondary Recrystallization of Grain-Oriented Silicon Steel. DOI: 10.3390/met14020152

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is it necessary to use an S-type thermocouple with an alumina protection tube? Master Molten Iron Monitoring

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What types of industrial applications are MoSi2 heating elements best suited for? Maximize High-Temp Stability

- How do alkali, alkaline oxides, and melting metals affect silicon carbide heating elements? Prevent Damage for Long Lifespan

- Why is a high-purity quartz tube utilized as a reaction chamber for plastic pyrolysis? Top Benefits and Performance

- What are the properties of molybdenum disilicide? Unlock High-Temp Performance and Safety Insights

- How can the power of a heating element be increased? Boost Heat Output Safely with Key Methods

- What material properties make MoSi2 heating elements suitable for high-temperature applications? Discover Self-Healing Durability