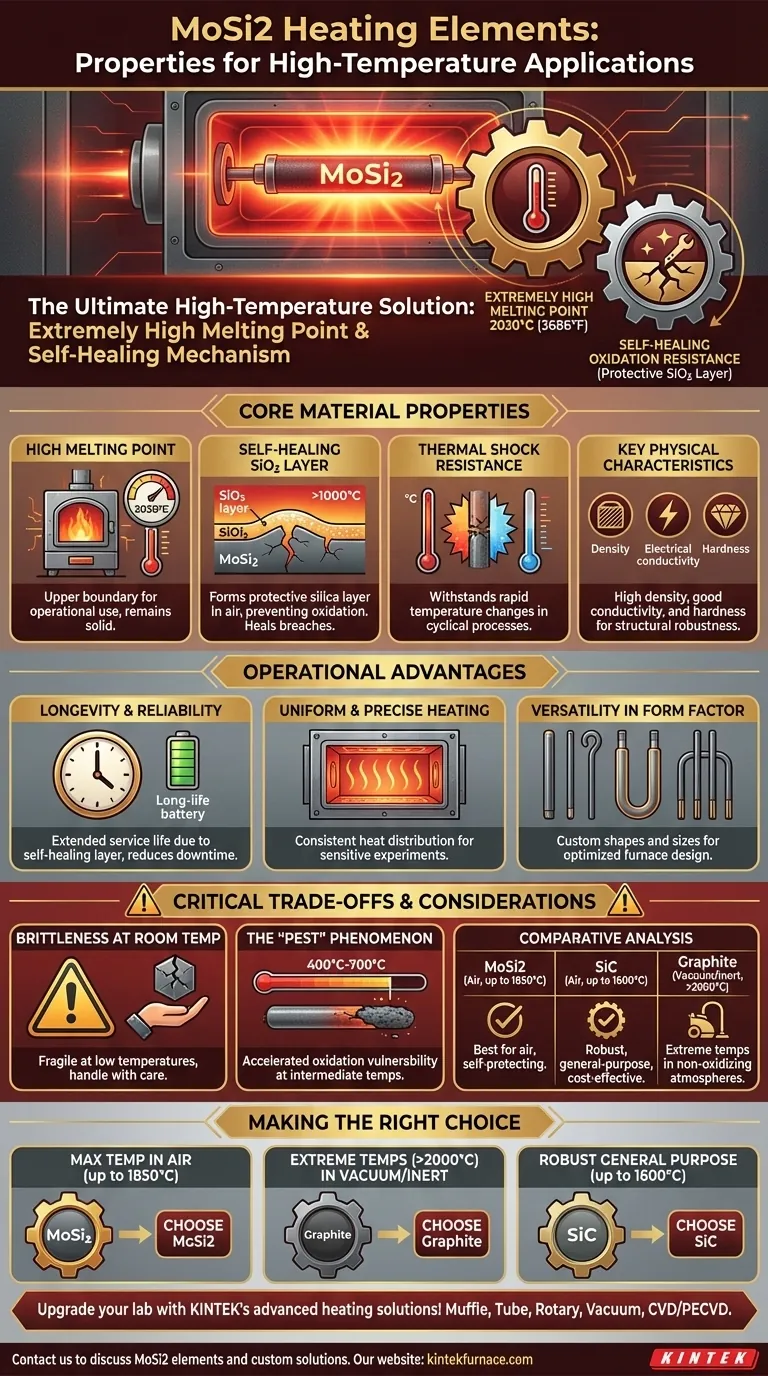

The fundamental suitability of Molybdenum Disilicide (MoSi2) heating elements for high-temperature applications stems from a unique combination of an extremely high melting point and a remarkable self-healing mechanism. Unlike other materials that degrade, MoSi2 forms a protective, glass-like layer at high temperatures that prevents its own destruction, allowing it to operate reliably in oxidizing atmospheres where many other elements would fail.

The critical factor is not just that MoSi2 can withstand heat, but that it actively protects itself from oxygen at high temperatures. This self-healing oxidation resistance is what grants it a long and stable service life in furnaces and other demanding environments.

The Core Properties of Molybdenum Disilicide (MoSi2)

To understand why MoSi2 is a dominant material in this field, we must look beyond its temperature rating and examine the underlying chemical and physical properties that enable its performance.

Extremely High Melting Point

The foundation of any high-temperature material is its ability to remain solid. Molybdenum Disilicide has a very high melting temperature of 2030°C (3686°F), which establishes the upper boundary for its operational use.

Self-Healing Oxidation Resistance

This is the most important property of MoSi2. At temperatures above 1000°C, the material reacts with oxygen in the atmosphere to form a thin, non-porous layer of protective silica (SiO2), or quartz glass, on its surface.

This silica layer is highly stable and prevents further oxidation of the underlying MoSi2. If the layer is cracked or damaged, the exposed MoSi2 simply forms new silica to "heal" the breach, giving the element its renowned longevity.

Excellent Thermal Shock Resistance

The same protective SiO2 layer that prevents oxidation also grants the element exceptional resistance to thermal shock. This means it can withstand rapid changes in temperature without cracking or failing, a crucial attribute for cyclical industrial processes.

Key Physical Characteristics

In addition to its thermal properties, MoSi2 possesses high density, good electrical conductivity, and high hardness. This combination ensures the element is not only heat-resistant but also structurally robust and efficient at converting electrical energy into heat.

Understanding the Operational Advantages

These material properties translate directly into tangible benefits for research and industrial applications.

Longevity and Reliability

The self-healing nature of the silica layer means MoSi2 elements have a very long service life, especially when operated at consistently high temperatures. This reduces downtime, maintenance costs, and replacement frequency.

Uniform and Precise Heating

MoSi2 elements can be engineered to provide highly uniform heat distribution within a furnace chamber. Their chemical inertness and stability ensure this performance is consistent over time, which is critical for material synthesis and sensitive experiments.

Versatility in Form Factor

These elements can be manufactured in a wide array of shapes and sizes, including straight rods, U-bends, and custom configurations. This flexibility allows furnace designers to optimize heating efficiency for specific equipment and processes.

Critical Trade-offs and Considerations

No material is perfect for every scenario. True expertise comes from understanding not only the strengths but also the limitations.

Brittleness at Room Temperature

Like many ceramic-based materials, MoSi2 is very brittle at lower temperatures. Care must be taken during installation and handling to avoid impact, which can easily cause the element to fracture.

Comparison to SiC Elements

Silicon Carbide (SiC) elements are another common choice for high-temperature applications. SiC is exceptionally durable and offers great performance, but MoSi2 can typically reach higher operating temperatures in an air atmosphere. The choice often depends on the specific temperature and budget requirements of the application.

Comparison to Graphite Elements

Graphite can operate at extreme temperatures, reaching up to 3000°C. However, it will rapidly oxidize and burn away in the presence of air. Therefore, graphite is only suitable for use in a vacuum or inert gas atmosphere, whereas MoSi2's primary advantage is its ability to function in air.

The "Pest" Phenomenon

MoSi2 has a known vulnerability to accelerated oxidation at intermediate temperatures, typically between 400°C and 700°C. This phenomenon, known as "pesting," can cause the element to disintegrate. For this reason, it is critical to move through this temperature range quickly during both heat-up and cool-down.

Making the Right Choice for Your Application

Your final decision should be guided by your specific operational environment and goals.

- If your primary focus is maximum temperature in an air atmosphere (up to 1850°C): MoSi2 is the definitive choice due to its self-protecting silica layer.

- If your primary focus is extreme temperatures (>2000°C) in a vacuum or inert atmosphere: Graphite is the superior material, as it will not face oxidation.

- If your primary focus is robust, general-purpose heating up to 1600°C: SiC elements are a highly durable and often more cost-effective alternative to consider.

By understanding the unique oxidative behavior of MoSi2, you can confidently specify the right heating element to ensure the success and efficiency of your high-temperature process.

Summary Table:

| Property | Key Benefit |

|---|---|

| High Melting Point (2030°C) | Enables operation at extreme temperatures |

| Self-Healing Oxidation Resistance | Forms protective SiO2 layer for long service life |

| Excellent Thermal Shock Resistance | Withstands rapid temperature changes without damage |

| High Density and Hardness | Provides structural robustness and efficiency |

Upgrade your lab's high-temperature capabilities with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering reliable and efficient performance. Don't settle for less—contact us today to discuss how our MoSi2 heating elements and other solutions can enhance your processes and drive success!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance