In short, you increase a heating element's power by decreasing its electrical resistance. The two most common ways to achieve this are by reducing the length of the element's wire or by increasing the diameter of that wire. Both actions create an easier path for electricity, causing the element to draw more current and produce more heat at a given voltage.

The core principle is an inverse relationship: to increase power output, you must decrease the heating element's resistance. For any device plugged into a standard wall outlet, the voltage is fixed. Lowering the resistance is the only way to draw more current and thus generate more heat.

The Physics of Heating Power

To modify a heating element effectively, you must first understand the fundamental relationship between voltage, resistance, and power. This relationship governs how all resistive heaters work, from toasters to industrial furnaces.

The Power Formula That Matters

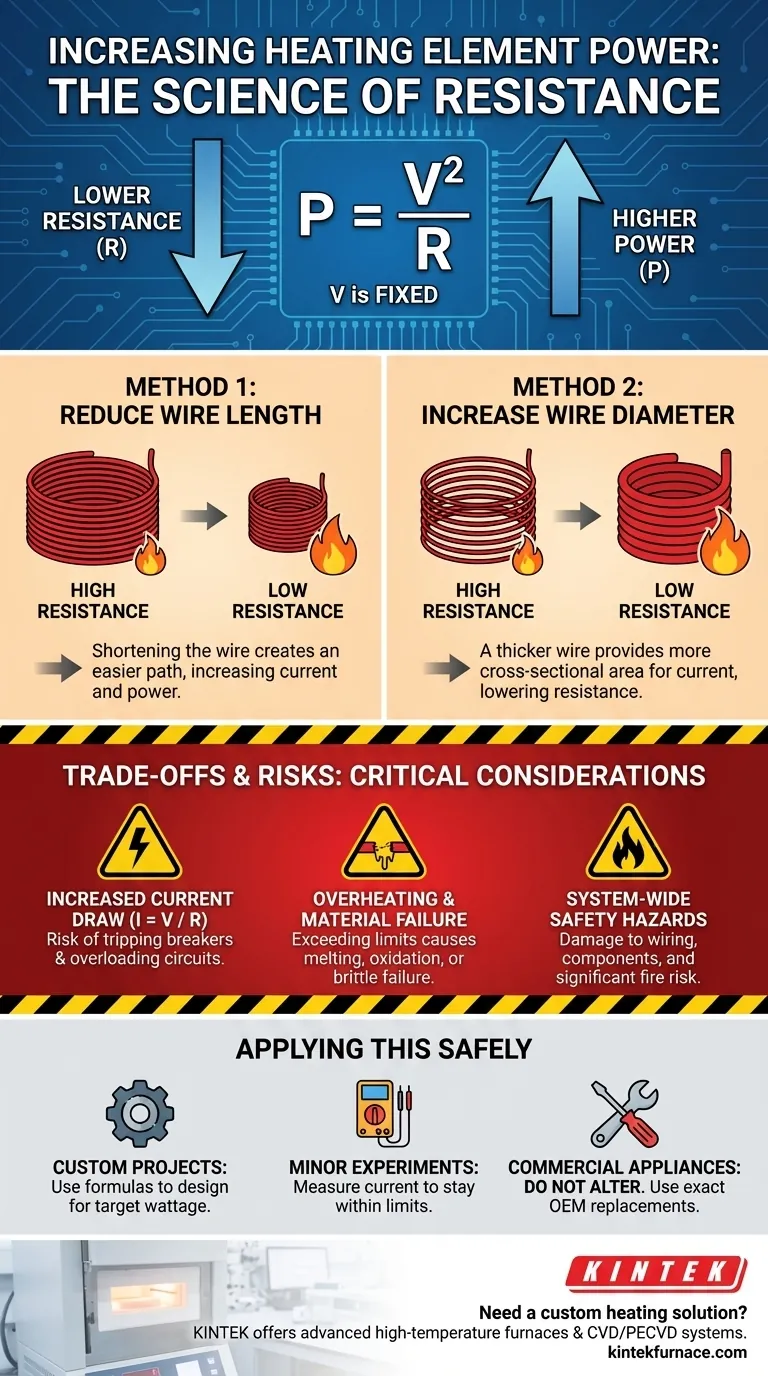

For a heating element connected to a fixed-voltage source like a wall outlet, the most important formula is Power (P) = Voltage (V)² / Resistance (R).

Because the voltage (V) is constant, this formula makes it clear that power is inversely proportional to resistance. If you reduce the resistance, the power output goes up. If you increase resistance, power goes down.

How Physical Dimensions Dictate Resistance

The resistance of a wire is determined by three factors: its length, its cross-sectional area, and the material it's made from (its resistivity).

A longer, thinner wire has higher resistance, while a shorter, thicker wire has lower resistance. Think of it like water flowing through a pipe: a long, narrow pipe restricts flow more than a short, wide one.

Method 1: Reducing the Element's Length

By shortening the wire, you reduce the total distance electricity has to travel. This decreases the overall opposition to the current.

With less resistance (R), the formula P = V²/R shows that the power output (P) will increase significantly.

Method 2: Increasing the Wire's Diameter

Using a thicker wire for the element increases its cross-sectional area. This provides more physical space for the electrical current to flow.

This "wider path" dramatically lowers the wire's resistance, causing it to draw more current and produce more heat for the same length.

Understanding the Trade-offs and Risks

Increasing the power of a heating element is not a simple tweak; it has critical consequences for the entire electrical system and the device's safety. Ignoring these trade-offs can lead to equipment failure or fire.

Increased Current Draw

Lowering an element's resistance will cause it to draw much more electrical current (Amps). The formula is Current (I) = Voltage (V) / Resistance (R).

Your home's circuits are protected by breakers or fuses rated for a maximum current (e.g., 15 or 20 Amps). A modified element can easily exceed this limit, tripping the breaker or, in a worst-case scenario, overloading the wiring in your walls.

Overheating and Material Failure

The element itself will get significantly hotter. Heating element wires, like Nichrome, are designed to operate up to a specific maximum temperature.

Pushing an element beyond its designed power rating can cause it to overheat, oxidize rapidly, become brittle, or simply melt, leading to permanent failure.

System-Wide Safety Hazards

A heating element is part of a larger system. The device's enclosure, wiring, and internal components were all designed to handle the heat produced by the original element.

Dramatically increasing the heat output can melt plastic components, damage internal wiring, and create a serious fire hazard. Commercial appliances are carefully engineered for safety, and modifying them voids this protection.

How to Apply This to Your Project

Before making any changes, you must evaluate your goal and the context of your project.

- If your primary focus is designing a new element for a custom project: Use the power formulas (P=V²/R and R=ρL/A) to calculate the precise length and diameter of wire needed to safely achieve your target wattage.

- If your primary focus is a minor power boost in a controlled experiment: Slightly shortening an existing element is the most direct method, but you must measure the change in current draw to ensure you do not exceed circuit limits.

- If your primary focus is repairing or modifying a commercial appliance: Do not alter the heating element. It is critical to replace it with an exact Original Equipment Manufacturer (OEM) part to maintain its safety and operational integrity.

Understanding these foundational principles empowers you to design and work with heating elements effectively and, most importantly, safely.

Summary Table:

| Method | Action | Effect on Resistance | Key Consideration |

|---|---|---|---|

| Reduce Length | Shorten the wire | Decreases | Risk of overheating and circuit overload |

| Increase Diameter | Use thicker wire | Decreases | Material limits and system compatibility |

Need a custom heating solution for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and safety with tailored solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis