The primary reason for using an electric furnace with three independent heating elements is to achieve precise zonal temperature control, which creates a highly stable, uniform heat field. In kinetic studies of ammonia (NH3) and diethyl ether (DEE) oxidation, this specific configuration is essential for eliminating internal temperature gradients that could skew experimental results.

By eradicating thermal inconsistencies, this setup ensures that observed phenomena—such as ignition temperatures and component shifts—are driven purely by the set experimental temperatures rather than local heat fluctuations.

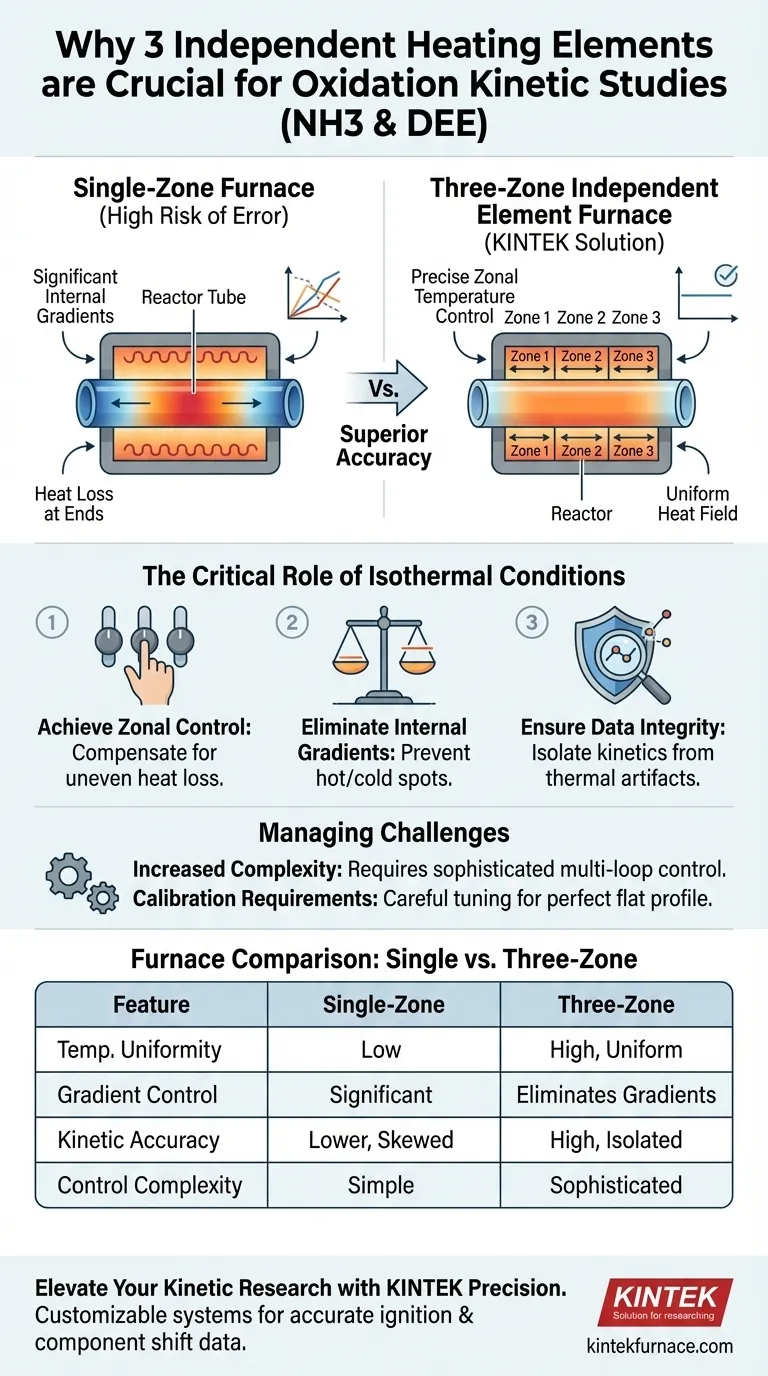

The Critical Role of Isothermal Conditions

To understand why a single heating element is insufficient for these specific oxidation studies, one must look at the requirements for kinetic accuracy.

Achieving Zonal Temperature Control

A furnace with three independent elements allows researchers to manipulate the heat profile across different sections—or zones—of the reactor.

This capability is vital because heat loss is rarely uniform across a reaction tube; the ends often lose heat faster than the center.

Eliminating Internal Gradients

By adjusting the power to the three independent elements, the system can compensate for uneven heat loss.

This results in a uniform heat field throughout the reaction zone.

Without this "zonal" adjustment, internal temperature gradients would form, creating hot or cold spots that distort the true reaction environment.

Ensuring Data Integrity

The ultimate goal of using this specialized furnace is to isolate the chemical kinetics from thermal artifacts.

Isolating Experimental Variables

In oxidation studies, researchers need to know that a reaction occurred because the overall temperature reached a specific set point, not because a localized hot spot triggered it early.

The three-element system guarantees that the temperature reading represents the entire reaction volume.

Accuracy in Ignition Studies

The primary reference highlights the importance of this setup for determining ignition temperatures.

If the heat field is not uniform, ignition data becomes unreliable, as the reaction might initiate at a temperature different from what is being recorded.

Precise thermal control ensures that component shifts and ignition points are accurate reflections of the chemical properties of ammonia and diethyl ether.

Understanding the Challenges

While a multi-zone furnace provides superior accuracy, it introduces specific operational complexities that must be managed.

Increased System Complexity

Using three independent elements requires a more sophisticated control strategy than a single-zone furnace.

You must monitor and balance three separate feedback loops to maintain the uniform field.

Calibration Requirements

Achieving a perfectly flat temperature profile requires careful tuning.

If the three zones are not synchronized correctly, you may inadvertently induce the very gradients you are trying to eliminate.

Making the Right Choice for Your Goal

When designing or evaluating an experimental setup for oxidation kinetics, the choice of furnace directly impacts data validity.

- If your primary focus is determining precise ignition thresholds: You must use a multi-zone furnace to ensure the ignition is triggered by the global temperature, not a local anomaly.

- If your primary focus is analyzing component shifts: Prioritize a uniform heat field to guarantee that the chemical conversion rates are consistent throughout the entire reactor length.

This specialized thermal configuration is the standard for ensuring that your kinetic data reflects chemical reality, not thermal error.

Summary Table:

| Feature | Single-Zone Furnace | Three-Zone Independent Element Furnace |

|---|---|---|

| Temperature Uniformity | High risk of heat loss at tube ends | Compensates for end-losses; uniform heat field |

| Gradient Control | Significant internal gradients | Eliminates internal gradients via zonal adjustment |

| Kinetic Accuracy | Lower; hot/cold spots skew ignition data | High; isolates chemical kinetics from thermal artifacts |

| Control Complexity | Simple single feedback loop | Sophisticated multi-loop control strategy |

| Application Suitability | General laboratory heating | Precise oxidation kinetics & ignition studies |

Elevate Your Kinetic Research with KINTEK Precision

Precision in oxidation studies starts with a uniform thermal environment. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnace systems specifically designed to eliminate thermal gradients through advanced multi-zone control. Backed by expert R&D and manufacturing, our high-temp furnaces are fully customizable to meet the rigorous demands of your ammonia and diethyl ether research.

Don't let thermal artifacts compromise your data integrity. Contact KINTEK today to discover how our customizable heating solutions can enhance your laboratory's efficiency and accuracy.

Visual Guide

References

- Adrián Ruiz-Gutiérrez, María U. Alzueta. A flow reactor study of NH<sub>3</sub>/DEE oxidation. DOI: 10.26754/jji-i3a.202511914

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the main advantages of ceramic heating elements over metal alternatives? Boost Efficiency and Durability

- What is the purpose of wrapping heating tapes around AP-SCVD gas lines? Prevent Condensation for Perfect Film Quality

- What is the basic function of heating elements? Convert Electricity to Controlled Heat Efficiently

- What distinguishes the different grades of Molybdenum Disilicide (MoSi2) elements? Match the Grade to Your Process Temperature

- What are the properties of silicon carbide as a heating element material? Uncover High-Temp Performance Benefits

- What heating elements are used in furnaces designed for higher temperatures? Explore SiC, MoSi2, Molybdenum, and Graphite Solutions

- What are the benefits of integrating heating elements and thermocouple systems? Enhance Precision for ECAP Processing

- What is the principle behind quartz heating? Discover Fast, Efficient Infrared Technology