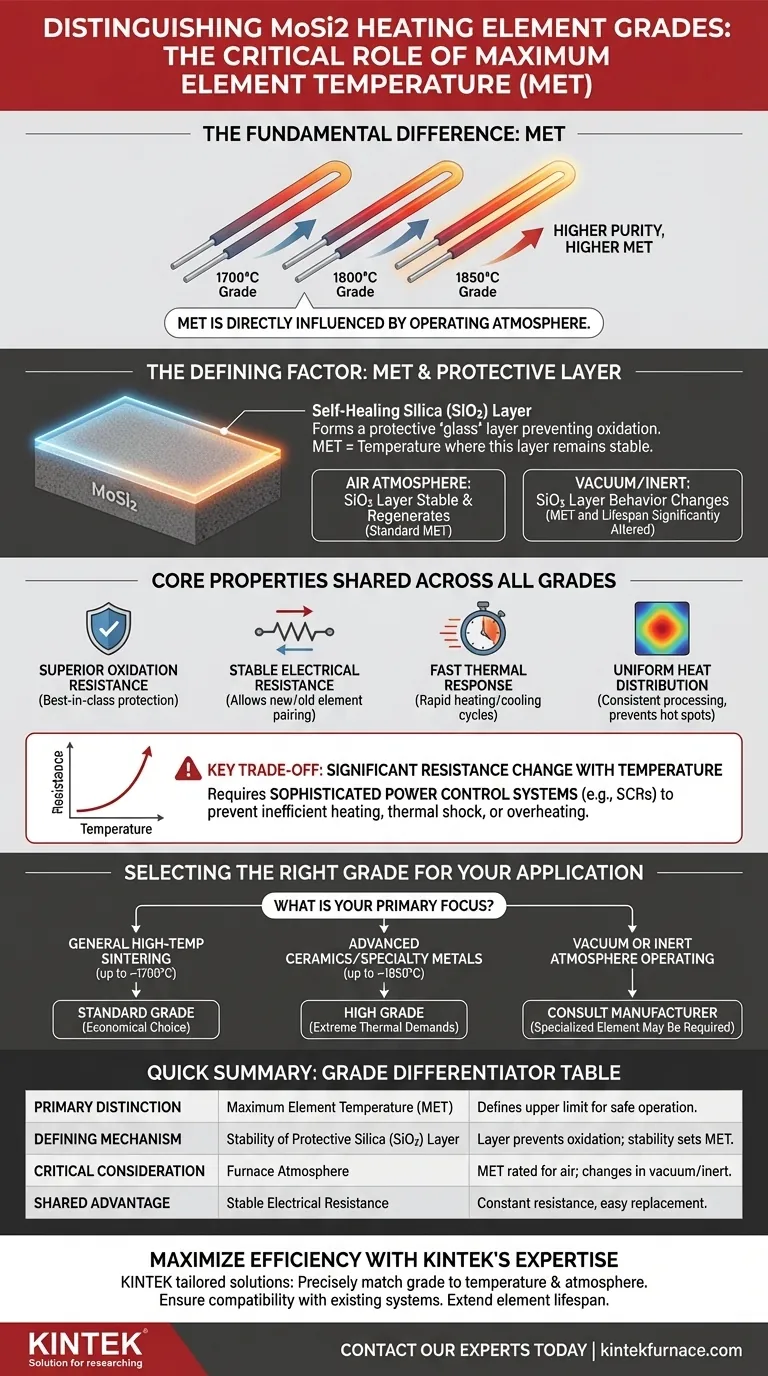

The fundamental difference between grades of Molybdenum Disilicide (MoSi2) heating elements is their Maximum Element Temperature (MET). Each grade is engineered to maintain its structural and chemical integrity up to a specific temperature ceiling, which is directly influenced by the operating atmosphere.

Choosing the right MoSi2 grade is not simply about selecting the highest temperature rating. It requires matching the element's capabilities to the specific thermal and atmospheric conditions of your process to ensure both operational efficiency and maximum element lifespan.

The Defining Factor: Maximum Element Temperature (MET)

The classification of MoSi2 elements is centered on one critical performance metric: the maximum temperature they can safely and reliably sustain. This capability is rooted in the material's unique chemistry at high temperatures.

How Grades Are Classified

MoSi2 element grades are typically named for their maximum recommended operating temperature in air, such as 1700°C, 1800°C, or 1850°C.

Higher-grade elements are composed of a purer, more refined material, allowing them to perform reliably at more extreme temperatures without premature failure.

The Critical Role of the Protective Silica Layer

All MoSi2 elements gain their exceptional high-temperature stability by forming a thin, self-healing layer of silica (SiO2) on their surface.

This protective "glass" layer prevents the underlying material from oxidizing further, allowing it to function in extreme heat. The MET of a specific grade is determined by the temperature at which this protective layer remains stable and effective.

Why Atmosphere Changes Everything

An element's MET is not a universal constant; it is highly dependent on the furnace atmosphere. The ratings are typically given for operation in air, where oxygen is available to form and regenerate the SiO2 layer.

In non-air or vacuum atmospheres, the behavior of the protective layer changes, which can significantly alter the element's maximum operating temperature and lifespan.

Core Properties Shared Across All Grades

While MET is the primary differentiator, all MoSi2 heating elements share a set of core advantages that make them suitable for demanding applications.

Superior Oxidation Resistance

The fundamental mechanism of the self-healing silica film provides all grades with best-in-class resistance to oxidation and corrosion at high temperatures.

Stable Electrical Resistance

Unlike some other element types, the resistance of MoSi2 elements remains stable over their long lifespan. This unique feature allows for new elements to be connected in series with older ones without issue.

Fast Thermal Response

MoSi2 elements possess excellent thermal responsiveness, enabling rapid heating and cooling cycles. This can significantly improve process efficiency and throughput.

Uniform Heat Distribution

These elements are known for providing even and consistent heat, which is critical for ensuring materials are processed uniformly and for preventing damaging hot spots within a furnace.

Understanding the Key Trade-off

The primary operational challenge with MoSi2 elements is a direct consequence of their material properties and applies to all grades.

Significant Resistance Change with Temperature

The electrical resistance of a MoSi2 element changes substantially as it heats up from room temperature to its operating point.

This characteristic demands the use of sophisticated power control systems, typically using silicon-controlled rectifiers (SCRs), to manage the power delivery precisely. Failing to do so can lead to inefficient heating, thermal shock, or overheating.

How to Select the Right Grade for Your Application

Your choice should be guided by the specific demands of your process, balancing performance requirements with cost-effectiveness.

- If your primary focus is general high-temperature sintering (up to ~1700°C): A standard-grade element provides the necessary performance and is the most economical choice.

- If your primary focus is producing advanced ceramics or specialty metals (up to ~1850°C): You must select a high-grade element specifically rated for these extreme thermal demands.

- If your primary focus is operating in a vacuum or inert atmosphere: You must consult the manufacturer's specific data sheets, as standard MET ratings for air do not apply and a specialized element may be required.

Making an informed decision based on these factors ensures you achieve optimal performance and longevity from your heating elements.

Summary Table:

| Grade Differentiator | Key Factor | Why It Matters |

|---|---|---|

| Primary Distinction | Maximum Element Temperature (MET) | Defines the upper temperature limit for safe, reliable operation. |

| Defining Mechanism | Stability of Protective Silica (SiO2) Layer | The self-healing layer prevents oxidation; its stability sets the MET. |

| Critical Consideration | Furnace Atmosphere | MET is rated for air. Performance and lifespan change in vacuum or inert gases. |

| Shared Advantage | Stable Electrical Resistance | Resistance remains constant over time, allowing easy replacement and series connection. |

Maximize Your High-Temperature Process Efficiency with the Right MoSi2 Elements

Selecting the correct Molybdenum Disilicide grade is critical for achieving consistent results, preventing premature element failure, and optimizing your operational costs. The wrong choice can lead to inefficient heating, process inconsistencies, and unexpected downtime.

KINTEK's expert team is here to guide you. We don't just sell elements; we provide solutions tailored to your unique thermal and atmospheric requirements.

We will help you:

- Precisely match the MoSi2 grade to your specific maximum operating temperature and furnace atmosphere.

- Ensure compatibility with your existing or new furnace system and power controls.

- Extend element lifespan and improve process reliability through expert selection.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Our MoSi2 elements are engineered for superior performance in the most demanding applications.

Ready to achieve optimal thermal performance? Contact our heating experts today for a personalized consultation and let us help you select the perfect MoSi2 solution.

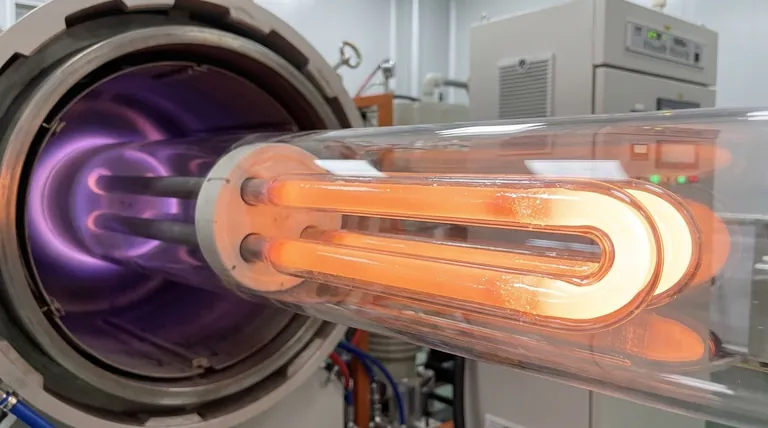

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?