At its core, molybdenum disilicide (MoSi2) is suitable for high-temperature applications because of its exceptionally high melting point of 2030°C and, most critically, its ability to form a protective, self-healing glass layer on its surface. This unique combination of thermal stability and active defense against oxidation makes it a premier material for components like furnace heating elements.

While its high melting point sets the stage, the true advantage of MoSi2 is its dynamic response to heat. It doesn't just endure high temperatures; it actively creates a shield of silica (SiO2) that grants it outstanding resistance to oxidation and thermal shock.

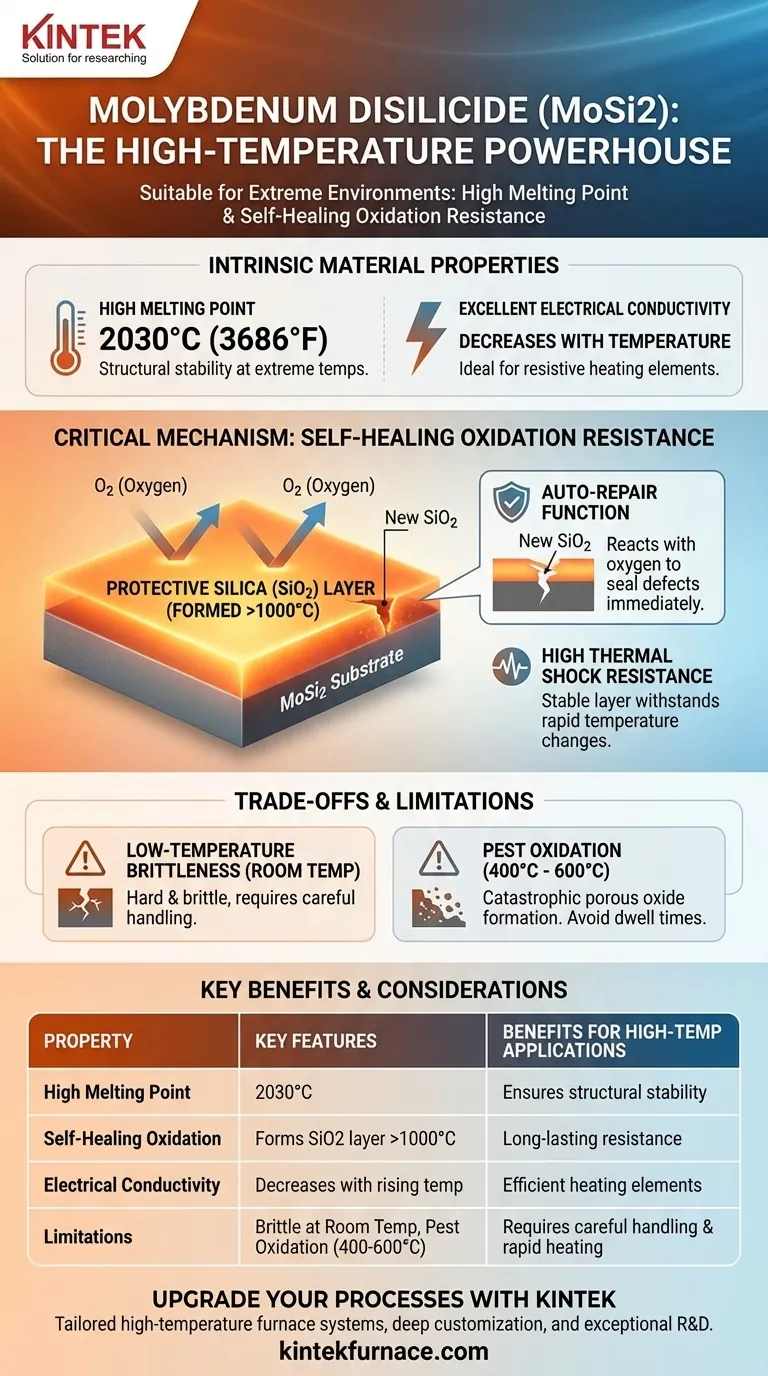

The Foundation: Intrinsic Material Properties

Before its unique protective mechanism kicks in, the fundamental nature of MoSi2 gives it a high operational ceiling.

High Melting Temperature

MoSi2 has a very high melting point of 2030°C (3686°F). This provides a significant buffer for applications that run at extreme temperatures, ensuring the material remains solid and structurally stable.

Excellent Electrical Conductivity

Unlike many ceramics, MoSi2 has good electrical conductivity that decreases as temperature rises. This behavior makes it an ideal material for resistive heating elements, where it can efficiently convert electrical energy into heat.

The Critical Mechanism: Self-Healing Oxidation Resistance

The standout feature of MoSi2 is not just its ability to resist oxidation, but its method for doing so. It creates a dynamic, renewable barrier.

Formation of the Protective Silica (SiO2) Layer

Above approximately 1000°C, the silicon within the MoSi2 material reacts with oxygen in the atmosphere. This reaction forms a thin, dense, and non-porous layer of glassy silica (SiO2) on the surface.

This silica layer acts as a highly effective barrier, preventing oxygen from reaching the underlying MoSi2 and causing further oxidation.

The "Auto-Repair" Function

This protective layer is "self-healing." If a crack or spall forms in the silica layer due to mechanical stress or thermal shock, the newly exposed MoSi2 underneath will immediately react with oxygen to form new SiO2, effectively sealing the defect.

This continuous repair process is the primary reason for the material's long service life in high-temperature, oxidizing environments.

High Thermal Shock Resistance

The stable, well-adhered silica layer helps the material withstand rapid changes in temperature without catastrophic failure. This is critical for furnaces and kilns that are frequently cycled on and off.

Understanding the Trade-offs and Limitations

No material is perfect. The same properties that make MoSi2 excellent for high-temperature use also introduce specific challenges and limitations.

Low-Temperature Brittleness

Like many advanced ceramics and intermetallic compounds, MoSi2 is very hard and brittle at room temperature. This makes it susceptible to fracture from mechanical impact and requires careful handling during installation and maintenance.

The "Pest" Oxidation Problem

In a specific intermediate temperature range, typically 400°C to 600°C, MoSi2 can undergo a catastrophic form of oxidation known as "pest oxidation." At these temperatures, it forms a porous, non-protective oxide that can cause the material to disintegrate into powder.

This makes MoSi2 unsuitable for applications that dwell for long periods in this moderate temperature zone. It is designed to be heated rapidly through this range.

High Hardness and Machinability

The material's high hardness contributes to excellent wear resistance but also makes it very difficult and expensive to machine. Components are typically formed into their final shape before the final sintering process, as post-sintering modification is challenging.

Making the Right Choice for Your Application

The decision to use MoSi2 must be based on a clear understanding of its operational window.

- If your primary focus is continuous operation in extreme-temperature (1000°C to 1800°C) oxidizing environments: MoSi2 is an exceptional choice due to its self-healing silica layer.

- If your application involves frequent and slow cycling through moderate temperatures (400-600°C): You must design the system to pass through this "pest" region quickly to avoid material degradation.

- If your component is subject to high mechanical impact at room temperature: The inherent brittleness of MoSi2 is a significant risk factor that must be mitigated through careful system design and handling.

By weighing its unique protective mechanism against its known limitations, you can effectively leverage molybdenum disilicide in the most demanding high-temperature systems.

Summary Table:

| Property | Key Features | Benefits for High-Temp Applications |

|---|---|---|

| High Melting Point | 2030°C | Ensures structural stability at extreme temperatures |

| Self-Healing Oxidation | Forms protective SiO2 layer above 1000°C | Provides long-lasting resistance to oxidation and corrosion |

| Electrical Conductivity | Decreases with rising temperature | Ideal for efficient resistive heating elements |

| Thermal Shock Resistance | Stable silica layer adhesion | Withstands rapid temperature changes in cycling furnaces |

| Limitations | Brittle at room temperature, pest oxidation at 400-600°C | Requires careful handling and rapid heating through critical ranges |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and durability. Contact us today to discuss how we can support your high-temperature applications with reliable, high-performance equipment!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity