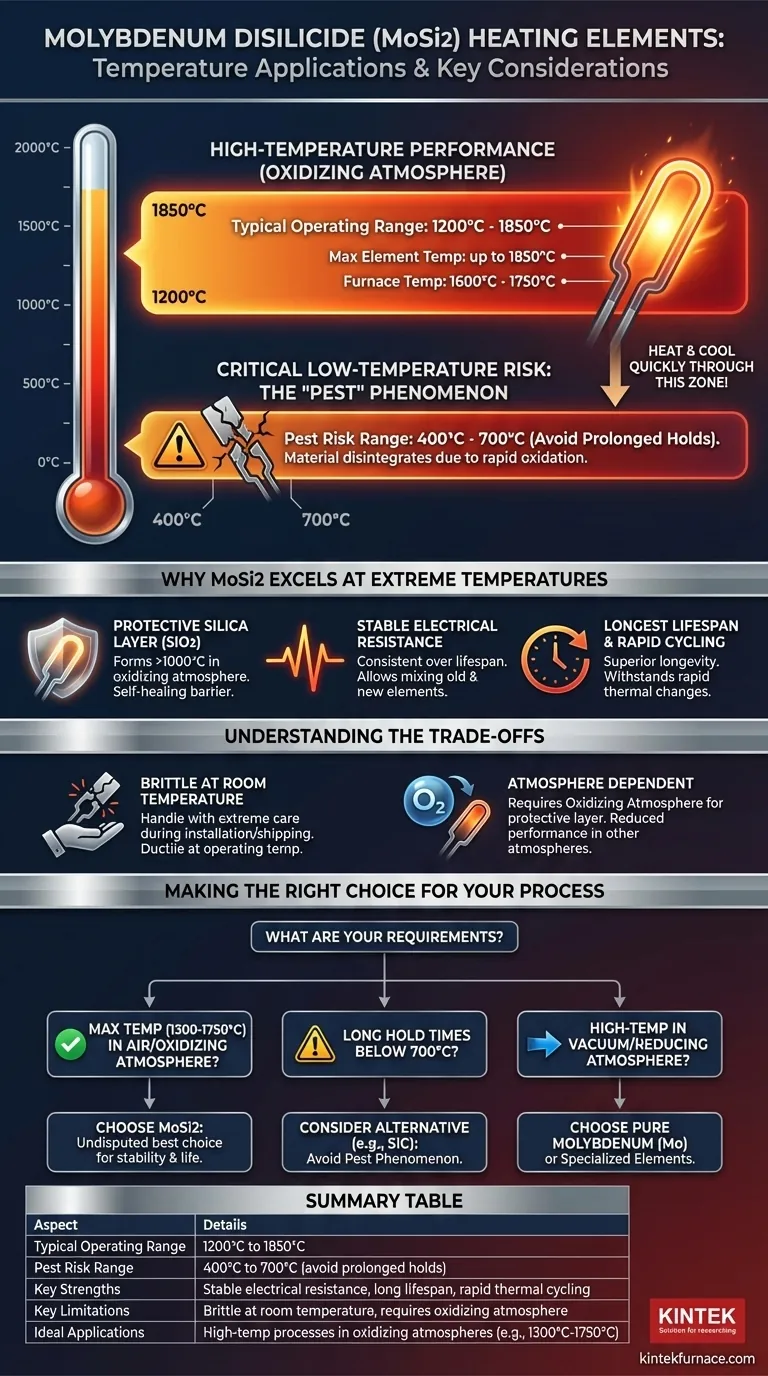

For high-temperature applications, Molybdenum Disilicide (MoSi2) heating elements are designed for a typical operating range starting at 1200°C and can reach element temperatures as high as 1850°C. However, they are vulnerable to a disintegration effect known as "pest" if held for extended periods at lower temperatures, specifically in the 400°C to 700°C range.

MoSi2 elements are unmatched for reaching extreme temperatures in oxidizing atmospheres, but their use requires a clear understanding of a critical low-temperature weakness. The key to success is rapidly heating through the sub-700°C range to avoid material failure.

Why MoSi2 Excels at Extreme Temperatures

The unique properties of Molybdenum Disilicide make it a premier choice for the most demanding high-temperature industrial and laboratory furnaces. Its performance is rooted in its chemical behavior in the presence of oxygen.

The Protective Silica Layer

At temperatures above approximately 1000°C, MoSi2 reacts with oxygen in the atmosphere to form a thin, non-porous layer of silica (SiO2) on its surface.

This passivation layer is self-healing and acts as a protective barrier, preventing further oxidation of the underlying element material even at extreme heat.

Maximum Operating Temperatures

MoSi2 elements can achieve exceptionally high surface temperatures, with some grades rated for up to 1850°C (3362°F).

This allows furnace chambers to reliably reach and maintain working temperatures of 1600°C to 1750°C, depending on furnace design and insulation.

Stability and Longevity

Unlike many other element types, MoSi2 maintains a stable electrical resistance over its life. This stability allows for new and old elements to be connected in series without issue.

They are also capable of withstanding rapid thermal cycling and boast the longest inherent lifespan of all common metallic or ceramic heating elements.

Understanding the Trade-offs of MoSi2

While its high-temperature performance is exceptional, MoSi2 is not a universal solution. Its effective use depends on managing two significant limitations.

The "Pest" Phenomenon: A Critical Low-Temperature Risk

The most significant drawback of MoSi2 is a form of accelerated, low-temperature oxidation known as "pest" disintegration.

This occurs when the element is held for prolonged periods within a temperature range of approximately 400°C to 700°C. In this window, the material can rapidly oxidize and crumble into a powder.

Therefore, furnace controllers must be programmed to heat up and cool down quickly through this critical temperature zone to prevent element failure.

Brittleness at Room Temperature

MoSi2 is a cermet (ceramic-metallic composite) and is very brittle at room temperature. The elements must be handled with extreme care during shipping, storage, and installation to avoid fracture.

Once at operating temperature, however, the material becomes more ductile and is not susceptible to mechanical shock.

Atmosphere is Key

The protective silica layer that gives MoSi2 its high-temperature durability only forms in an oxidizing atmosphere.

While they can be used in other atmospheres, their maximum temperature and lifespan may be significantly reduced. For high-temperature vacuum or reducing atmosphere applications, pure Molybdenum (Mo) elements are often a more suitable choice.

Making the Right Choice for Your Process

Selecting the correct heating element is critical for furnace reliability and process success. Your decision should be based on the specific temperature and atmospheric requirements of your application.

- If your primary focus is achieving maximum temperature (1300°C - 1750°C) in an air or oxidizing atmosphere: MoSi2 is the undisputed best choice for its stability and long life.

- If your process requires long hold times below 700°C: MoSi2 is a high-risk option, and you should consider alternative elements like Silicon Carbide (SiC) to avoid the "pest" phenomenon.

- If your primary focus is high-temperature operation in a vacuum or reducing atmosphere: Pure Molybdenum (Mo) or other specialized elements are better suited for these conditions.

By understanding both its unparalleled strengths and its specific vulnerabilities, you can effectively leverage MoSi2 for reliable, extreme-temperature heating.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Operating Range | 1200°C to 1850°C |

| Pest Risk Range | 400°C to 700°C (avoid prolonged holds) |

| Key Strengths | Stable electrical resistance, long lifespan, rapid thermal cycling |

| Key Limitations | Brittle at room temperature, requires oxidizing atmosphere for protection |

| Ideal Applications | High-temperature processes in oxidizing atmospheres (e.g., 1300°C-1750°C) |

Need reliable high-temperature furnace solutions? KINTEK specializes in advanced heating elements like MoSi2, offering products such as Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our strong R&D and in-house manufacturing, we provide deep customization to meet your unique experimental needs. Contact us today to enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering