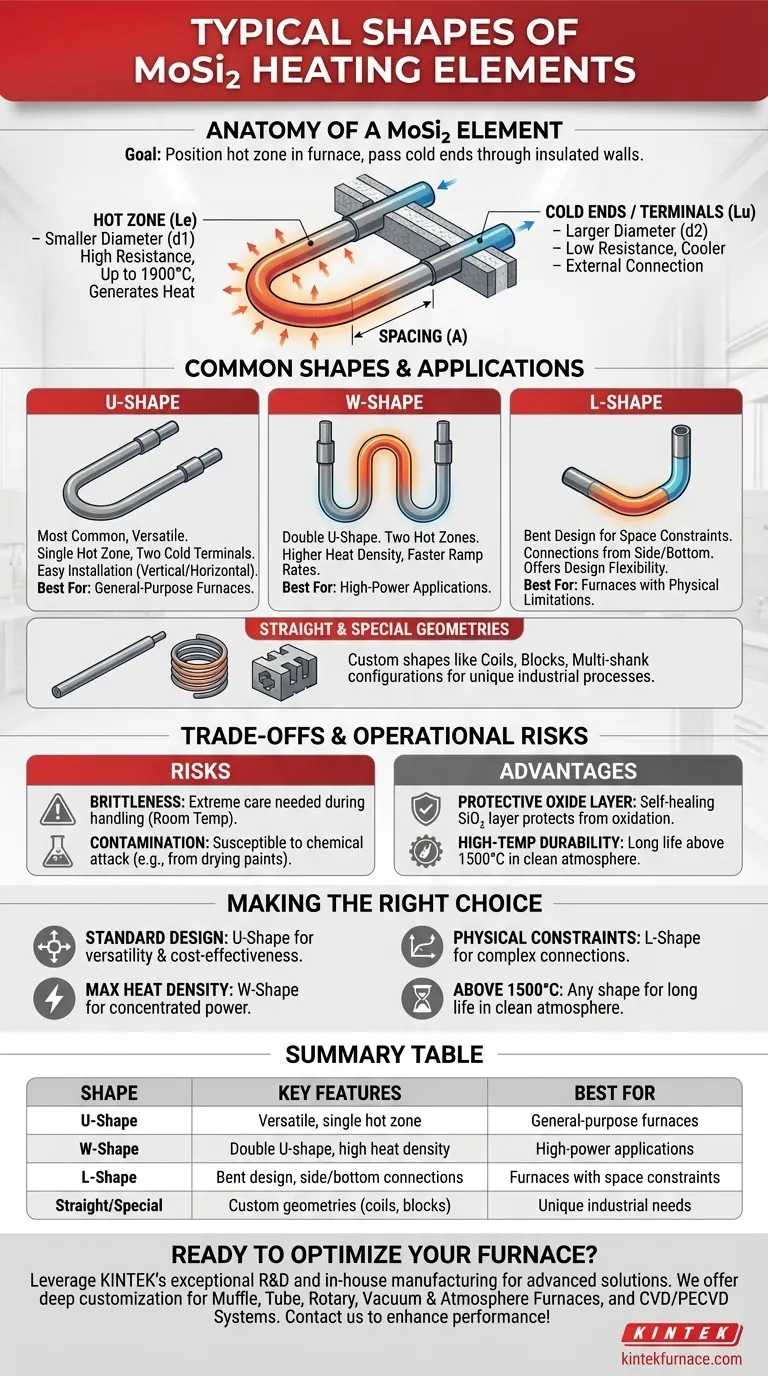

In practice, Molybdenum Disilicide (MoSi₂) heating elements are fabricated into several standard shapes to accommodate different furnace designs and heating requirements. The most common and versatile geometries are the U-shape, W-shape, and L-shape. These forms, along with more specialized options, are engineered to optimize heat distribution and simplify electrical connections outside the heated chamber.

The choice of a MoSi₂ element's shape is a direct function of furnace design. The goal is to position the slender, heat-generating "hot zone" correctly within the furnace, while the thicker, non-heating "cold ends" pass through the insulated walls for safe and efficient electrical connection.

The Anatomy of a MoSi₂ Element

To understand why different shapes exist, you must first understand the two distinct sections of a typical element.

The Hot Zone (Le)

The hot zone is the active, heat-producing section of the element. It has a smaller diameter (d1) which gives it higher electrical resistance. When current flows, this resistance generates intense heat, allowing the element surface to reach temperatures up to 1900°C.

The Cold Ends / Terminals (Lu)

The cold ends, or terminals, are the thicker sections (d2) at the ends of the element. Their larger diameter results in much lower electrical resistance, so they remain significantly cooler than the hot zone. These terminals are designed to pass through the furnace insulation for external power connection.

The U-Bend and Spacing (A)

The bend connecting the two legs of an element (as in a U-shape) and the distance between those legs (the 'A' spacing) are critical design parameters. These dimensions must match the furnace's geometry and the placement of the terminal holes in the furnace wall.

Common Shapes and Their Applications

The shape of an element is determined by how the hot and cold zones are arranged to fit a specific furnace.

U-Shape

This is the most common and versatile configuration. It consists of a single hot zone bent into a "U," with two cold terminals. U-shaped elements are easy to install either vertically or horizontally and are suitable for a wide range of general-purpose furnaces.

W-Shape

A W-shape is effectively a double U-shape, featuring three legs and providing two hot zones. This design delivers more heating power within a compact footprint, making it ideal for applications that demand higher heat density or faster ramp rates.

L-Shape

L-shaped elements are used when furnace design constraints prevent terminals from exiting straight out the back or top. The bend allows connections to be made from the side or bottom of the furnace chamber, offering greater design flexibility.

Straight and Special Geometries

While less common for furnace chambers, straight rod elements are available. Manufacturers can also produce highly specialized shapes, including coils, blocks, or multi-shank configurations, to meet unique heating requirements for specific industrial processes.

Understanding the Trade-offs and Operational Risks

MoSi₂ elements offer exceptional high-temperature performance, but they come with specific operational considerations that are critical to understand.

Extreme Brittleness at Room Temperature

At ambient temperatures, MoSi₂ is very brittle and can be easily damaged. Extreme care must be taken during shipping, handling, and installation to avoid fracturing the element.

Susceptibility to Contamination

These elements are highly susceptible to chemical attack from contaminants. As noted by experienced technicians, failing to properly dry painted or colored materials before heating can release compounds that degrade the elements, shortening their life.

The Protective Oxide Layer

The key to a MoSi₂ element's longevity is the formation of a thin, self-healing layer of silicon dioxide (SiO₂) on its surface. This layer protects the underlying material from oxidation at high temperatures, making it ideal for continuous work in oxygen-rich atmospheres.

Superior High-Temperature Durability

Despite their fragility when cold, MoSi₂ elements are highly durable at extreme operating temperatures. When operated consistently above 1500°C, they often last significantly longer than Silicon Carbide (SiC) elements, provided the furnace atmosphere is kept clean.

Making the Right Choice for Your Goal

Selecting the correct element geometry is a crucial step in designing or maintaining a high-temperature furnace. Your decision should be guided by the specific thermal and physical requirements of your application.

- If your primary focus is standard furnace design: The U-shape offers the best combination of versatility, ease of installation, and cost-effectiveness.

- If your primary focus is maximizing heat density: A W-shape element provides more heating power in a concentrated area, ideal for demanding processes.

- If your primary focus is accommodating physical constraints: L-shaped or other custom-bent elements are the solution when terminal connections cannot be straight.

- If your primary focus is operating above 1500°C: Any MoSi₂ shape provides excellent longevity, provided you maintain a clean, non-reactive furnace atmosphere.

Ultimately, the element's geometry must serve the furnace's thermal design, ensuring heat is delivered precisely and efficiently where it is needed.

Summary Table:

| Shape | Key Features | Best For |

|---|---|---|

| U-Shape | Versatile, easy to install, single hot zone | General-purpose furnaces |

| W-Shape | Double U-shape, two hot zones, high heat density | High-power or fast ramp rate applications |

| L-Shape | Bent design for side/bottom connections | Furnaces with space constraints |

| Straight/Special | Custom geometries like coils or blocks | Unique industrial heating needs |

Ready to optimize your high-temperature furnace with the perfect MoSi2 heating element? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your lab's needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your furnace performance and efficiency!

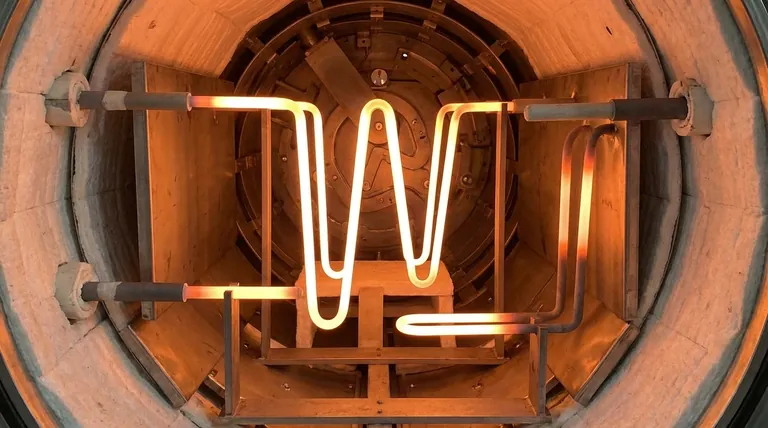

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement