At its core, silicon carbide (SiC) is a premier material for high-temperature heating elements due to its unique combination of thermal resilience, chemical stability, and structural integrity. It reliably generates extreme heat in demanding industrial environments where most metallic elements would fail, offering superior resistance to oxidation, corrosion, and thermal shock.

The true value of silicon carbide is not just its ability to get incredibly hot, but its capacity to perform reliably and efficiently at those temperatures over a long service life, ensuring process stability and reducing downtime.

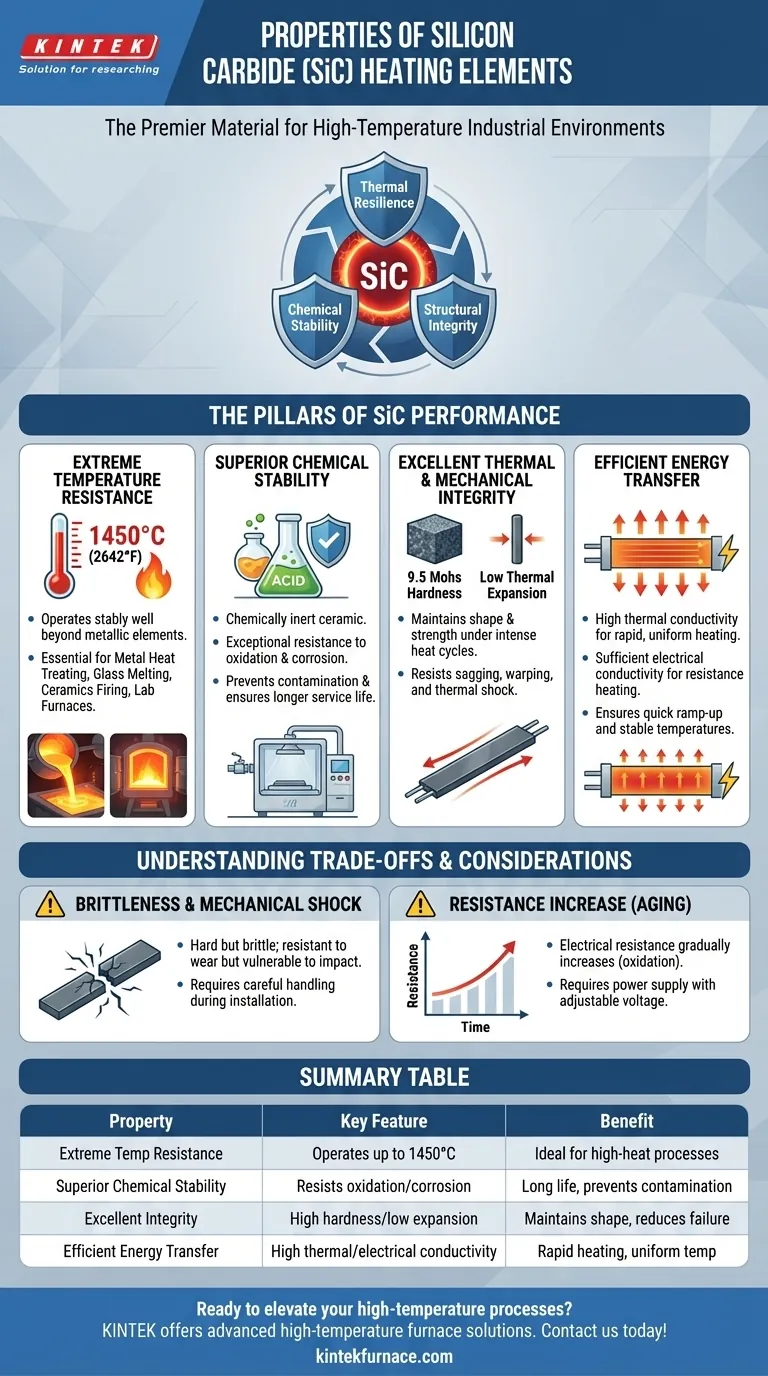

The Pillars of SiC Performance

Silicon carbide's effectiveness as a heating element is built on four key properties. Understanding how these work together is critical to evaluating its suitability for your application.

Extreme Temperature Resistance

SiC elements can operate stably at very high temperatures, typically up to 1450°C (2642°F). This capability far exceeds that of standard metallic heating elements.

This makes SiC essential for processes like metal heat treating, glass melting, ceramics firing, and laboratory furnace applications where sustained, extreme heat is a fundamental requirement.

Superior Chemical Stability

SiC is a chemically inert ceramic material, giving it exceptional resistance to oxidation and corrosion. It holds up well against acids and does not react with the materials being processed.

This inertness prevents contamination of the heated product and ensures the element does not degrade prematurely, even in harsh chemical atmospheres. This leads directly to a longer, more predictable service life.

Excellent Thermal and Mechanical Integrity

With a high hardness of 9.5 on the Mohs scale and very low thermal expansion, SiC elements maintain their shape and strength even when subjected to intense heat cycles.

This structural stability prevents the element from sagging, warping, or becoming brittle over time. It can withstand the immense stress of rapid heating and cooling without mechanical failure.

Efficient Energy Transfer

For a ceramic, SiC has relatively high thermal conductivity, which allows for rapid heating and uniform temperature distribution across the element's surface.

It also possesses sufficient electrical conductivity to function as a resistance heater, efficiently converting electrical energy into heat. This combination ensures quick ramp-up times and stable temperature maintenance.

Understanding the Trade-offs and Considerations

No material is without its practical limitations. An objective assessment of SiC requires acknowledging its specific operational characteristics.

Brittleness and Mechanical Shock

Like most advanced ceramics, silicon carbide is hard but brittle. It is highly resistant to wear and abrasion but can fracture if subjected to sudden mechanical impact or shock.

Care must be taken during installation, handling, and operation to avoid dropping the elements or subjecting them to physical stress.

Resistance Increase (Aging)

Over its service life, a SiC element's electrical resistance will gradually increase, a phenomenon known as aging. This is primarily caused by oxidation.

This change is predictable but must be accounted for in the power supply system. The system must be capable of providing increased voltage over time to maintain constant power output and temperature.

Making the Right Choice for Your Application

Selecting the right heating element material depends entirely on your primary engineering goals.

- If your primary focus is achieving the highest possible process temperatures: SiC is a leading candidate, capable of stable operation well above the limits of most metallic alloys.

- If your primary focus is long-term reliability in corrosive environments: Its chemical inertness makes SiC an excellent choice for ensuring process purity and maximizing element lifespan.

- If your primary focus is process stability and structural integrity: The material's resistance to thermal shock and deformation ensures predictable, repeatable performance over thousands of hours.

By understanding these properties and considerations, you can confidently determine if SiC's unique combination of high-temperature strength and chemical resilience aligns with your specific engineering goals.

Summary Table:

| Property | Key Feature | Benefit |

|---|---|---|

| Extreme Temperature Resistance | Operates up to 1450°C | Ideal for high-heat processes like metal treating and ceramics |

| Superior Chemical Stability | Resists oxidation and corrosion | Ensures long service life and prevents contamination |

| Excellent Thermal/Mechanical Integrity | High hardness and low thermal expansion | Maintains shape under thermal stress, reducing failure risk |

| Efficient Energy Transfer | High thermal and electrical conductivity | Enables rapid heating and uniform temperature distribution |

Ready to elevate your high-temperature processes with reliable silicon carbide heating solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism