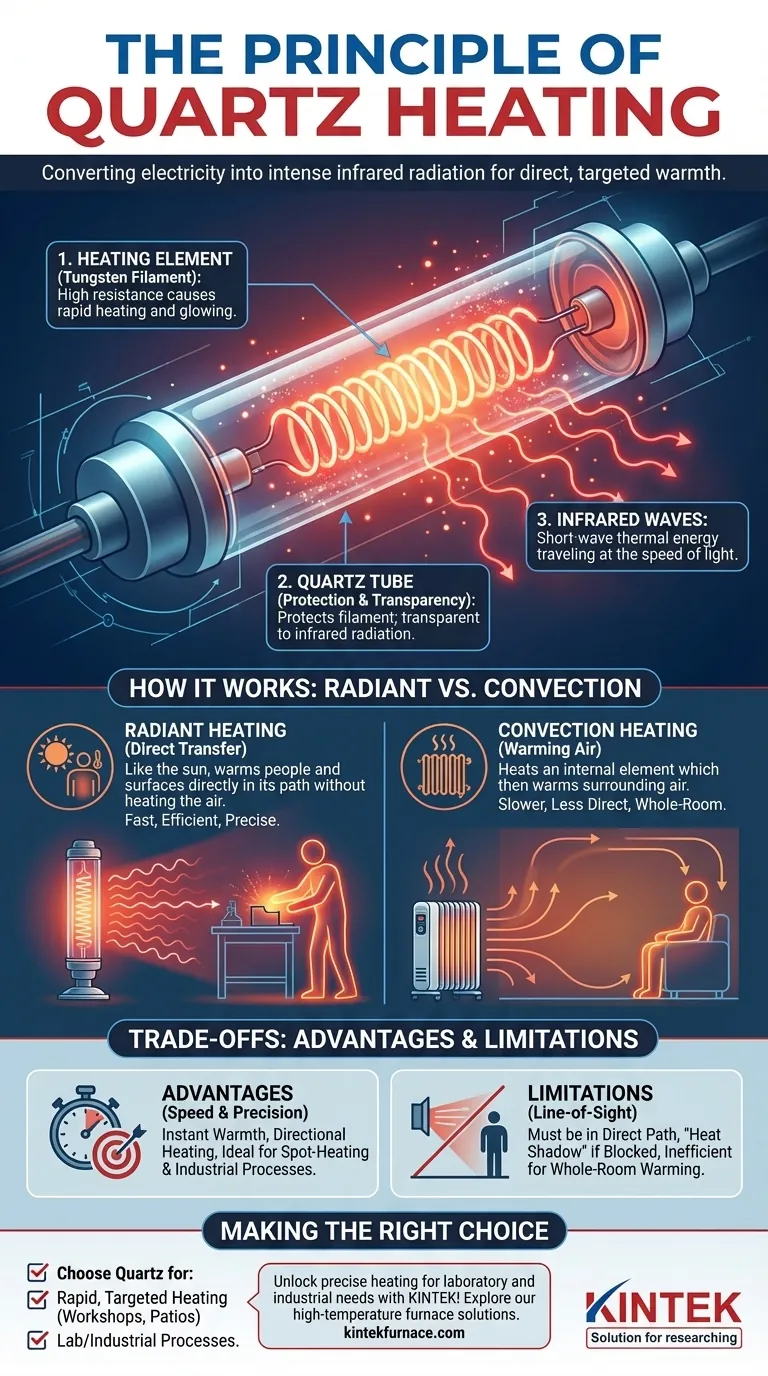

At its core, a quartz heater works by converting electricity into intense infrared radiation. A heating element, typically made of a tungsten filament, is housed inside a protective quartz glass tube. This element glows when energized, emitting thermal energy that travels in straight lines to directly warm people and objects in its path, much like the sun warms the earth.

Unlike conventional heaters that slowly warm the surrounding air, quartz heaters transfer energy directly to surfaces using infrared waves. This makes them exceptionally fast, efficient, and precise for targeted heating.

How Quartz Heaters Generate Infrared Radiation

The process involves a few key components working in concert to produce and direct heat. Understanding each part reveals why this technology is so distinct.

The Role of the Heating Element

When you turn on a quartz heater, electricity flows through a coiled filament. This filament has high electrical resistance, which causes it to heat up rapidly and glow, reaching very high temperatures.

The Purpose of the Quartz Tube

The glowing filament is encased in a tube made of quartz glass. This tube serves two critical functions: it protects the delicate filament from the air and physical damage, and its material properties are highly transparent to infrared radiation, allowing the heat to pass through with minimal loss.

The Power of Infrared Waves

The intense heat from the filament is emitted as short-wave infrared radiation. This is a form of electromagnetic energy that travels at the speed of light. It does not require a medium like air to propagate, allowing it to transfer energy directly to any object it strikes.

The Key Principle: Radiant vs. Convection Heating

The true principle behind quartz heating is best understood by contrasting it with the more common convection method. This distinction is the source of all its unique strengths and weaknesses.

Radiant Heating: A Direct Transfer of Energy

Imagine standing in the sun on a cool, windy day. Even though the air is chilly, you feel the warmth of the sun on your skin. This is radiant heat. Quartz heaters operate on this same principle, warming you directly without first needing to warm the air in between.

The Function of Reflectors

Most quartz heaters have a polished reflector behind the quartz tube. This reflector is optically designed to direct the infrared waves into a specific beam or pattern, concentrating the heat where it is needed most and preventing energy from being wasted.

Convection Heating: Warming the Air

In contrast, most common space heaters work via convection. They heat an internal element which in turn warms the surrounding air. This warm air then rises and circulates, gradually raising the ambient temperature of the entire room. This process is slower and less direct.

Understanding the Trade-offs

The "line-of-sight" nature of radiant heat creates a clear set of advantages and limitations that define its ideal use cases.

The Advantage: Speed and Precision

The primary benefit of quartz heating is its speed. You feel the warmth almost instantly because you don't have to wait for the air in the room to heat up. The use of reflectors allows for precise, directional heating, making it perfect for industrial tasks like drying paint or spot-heating a workbench.

The Limitation: "Line-of-Sight" Heating

The main drawback is that you must be in the direct path of the infrared waves to feel their effect. If an object blocks the heater, it will create a "heat shadow." The heat is concentrated on surfaces and doesn't distribute evenly throughout a space.

Inefficiency for Whole-Room Warming

Because a quartz heater is designed to heat objects rather than air, it is generally an inefficient choice for raising the overall ambient temperature of a large or poorly insulated room.

Making the Right Choice for Your Goal

Selecting the correct heating technology depends entirely on your objective. A quartz heater is a specialized tool, not a universal solution.

- If your primary focus is rapid, targeted heating: A quartz heater is an excellent choice for a workshop, garage, or patio where you need to warm a specific area or person quickly.

- If your primary focus is industrial or lab processes: The precise, non-contact, and fast-acting nature of quartz heating makes it ideal for drying coatings, curing adhesives, and other temperature-sensitive tasks.

- If your primary focus is heating an entire enclosed room evenly: A convection heater or an oil-filled radiator is a much more suitable and effective technology for the job.

By understanding the principle of direct radiant heat, you can deploy this technology where it provides the most value and avoid using it in situations where it would be inefficient.

Summary Table:

| Aspect | Description |

|---|---|

| Principle | Converts electricity to infrared radiation for direct heating of objects and people. |

| Key Components | Tungsten filament, quartz glass tube, reflector. |

| Heating Type | Radiant heating (direct energy transfer), not convection. |

| Advantages | Fast, efficient, precise, and ideal for targeted applications. |

| Limitations | Line-of-sight dependent, inefficient for whole-room warming. |

| Best Uses | Industrial processes, labs, workshops, and spot heating. |

Unlock the power of precise heating for your laboratory or industrial needs with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored to your unique requirements. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you need rapid, targeted heating or specialized thermal processing, KINTEK delivers reliable, efficient solutions to enhance your operations. Contact us today to discuss how we can support your projects with cutting-edge technology and expert guidance!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation