In applications demanding high performance and reliability, ceramic heating elements offer significant advantages over traditional metal alternatives. Their superiority stems from fundamental differences in material science, leading to better heat management, greater energy efficiency, and a substantially longer operational lifespan, particularly under demanding conditions.

The decision between ceramic and metal heaters extends beyond initial cost. It is a strategic choice between short-term savings and long-term operational excellence, where ceramic elements deliver superior value through efficiency, durability, and reduced maintenance over their entire service life.

The Core Difference: Material Stability Under Stress

The primary distinction between ceramic and metal heaters lies in how their core materials respond to the immense stress of repeated heating and cooling cycles.

Superior High-Temperature Performance

Ceramic materials possess significantly higher melting points than most metals used in heating elements. This allows them to operate at much higher temperatures without risk of melting, deforming, or changing their physical state.

This inherent thermal stability ensures consistent and reliable performance where metal elements would begin to fail.

Resistance to Oxidation and Corrosion

When metals are heated in the presence of air, they oxidize—a process similar to rusting. This oxidation degrades the metal, making it brittle and less effective over time.

Ceramic, being chemically inert, is highly resistant to both oxidation and chemical corrosion. This immunity is the primary reason for its exceptional longevity, even in harsh industrial environments.

Eliminating Thermal Fatigue

Metal heaters expand when hot and contract when cool. This constant cycle of expansion and contraction causes thermal fatigue, leading to micro-fractures and eventual failure.

Ceramic elements have a much lower coefficient of thermal expansion, making them far more resistant to the stresses of thermal cycling and ensuring a longer, more predictable service life.

Translating Stability into Operational Gains

This fundamental material stability translates directly into measurable improvements in efficiency, maintenance, and overall process quality.

Enhanced Energy Efficiency

Ceramic materials are excellent thermal insulators. This means they lose far less heat to the surrounding environment compared to metal elements.

By retaining heat more effectively, a ceramic element requires less energy to maintain its target temperature, leading to significant energy savings and lower operational costs.

Uniform Heat Distribution

Ceramic heaters are known for providing exceptionally uniform heat distribution across their entire surface. This eliminates "hot spots" that are common with metal coil heaters.

Consistent heating improves the quality and reliability of industrial processes, from plastics molding to food processing, by ensuring the workpiece is heated evenly.

Drastically Reduced Maintenance

The durability and resistance to degradation inherent in ceramic elements mean they require minimal maintenance. They do not need frequent inspection or replacement due to oxidation or fatigue.

In contrast, metal elements often require regular upkeep to manage corrosion and ensure safety, adding to the total cost of ownership through labor and downtime.

Understanding the Trade-offs

While ceramic offers clear advantages, a balanced assessment requires acknowledging where metal elements still have a place.

Initial Cost vs. Total Cost of Ownership

Metal heating elements typically have a lower upfront purchase price, making them an attractive option for projects with tight initial budgets or less demanding applications.

However, this initial saving is often offset by higher energy consumption, more frequent replacements, and increased maintenance needs, making the total cost of ownership for ceramic lower over the long term.

Mechanical Fragility

As a material, ceramic is more brittle than metal. It can be more susceptible to cracking or breaking from severe physical shock or impact.

In applications involving high vibration or the risk of direct impact, the ductility of a metal heater might be a necessary design consideration, though many ceramic heaters are engineered to be highly robust.

Making the Right Choice for Your Application

Your final decision should be guided by your project's specific priorities, balancing upfront costs against long-term performance and reliability.

- If your primary focus is the lowest initial cost for a non-critical application: A metal heater may be sufficient, but budget for higher energy use and future replacements.

- If your primary focus is long-term reliability and minimal downtime: Ceramic is the definitive choice for its exceptional durability and resistance to degradation.

- If your primary focus is energy efficiency and precise process control: The superior insulation and uniform heating of a ceramic element deliver unmatched performance.

By understanding these fundamental material differences, you can select a heating solution that aligns with your true operational goals and financial realities.

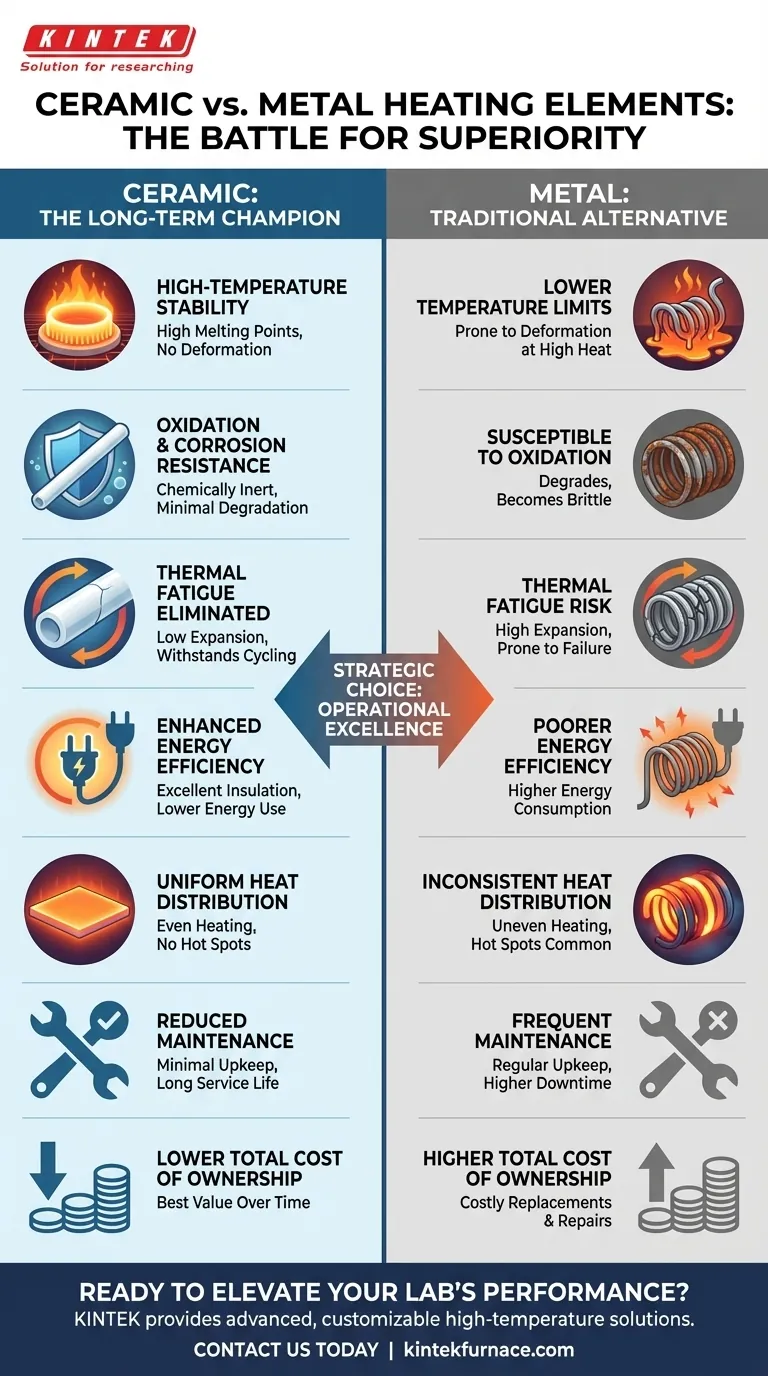

Summary Table:

| Advantage | Ceramic Heating Elements | Metal Heating Elements |

|---|---|---|

| High-Temperature Performance | Higher melting points, stable at extreme heat | Lower melting points, prone to deformation |

| Resistance to Oxidation/Corrosion | Chemically inert, minimal degradation | Susceptible to oxidation, leading to brittleness |

| Thermal Fatigue Resistance | Low expansion, withstands cycling | High expansion, prone to micro-fractures |

| Energy Efficiency | Excellent insulation, reduces energy use | Poorer insulation, higher energy consumption |

| Heat Distribution | Uniform heating, no hot spots | Inconsistent heating, hot spots common |

| Maintenance Needs | Minimal, long service life | Frequent, due to corrosion and fatigue |

| Total Cost of Ownership | Lower over long term | Higher due to replacements and upkeep |

Ready to elevate your lab's performance with advanced heating solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need ceramic heating elements for superior efficiency and durability or tailored systems for demanding applications, we're here to help. Contact us today to discuss how we can optimize your processes and reduce long-term costs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights